Flow rate, which leads to the volume of fluid traversing the system in a given time, is a crucial factor to consider. The valve’s capacity should suit the system’s highest discharge rate. Refrain from paying attention to account for these system prerequisites, which may give rise to a suboptimal functioning valve of an incorrect size, potentially culminating in the system’s failure.

Function of the valve (on/off, modulating)

When selecting an electric valve, it is essential to consider whether it operates as an on/off or modulating device. Designed to be completely opened or closed, on/off valves are most suitable for systems requiring straightforward on/off control, such as heating or cooling systems. Modulating valves, conversely, offer the capability to initiate or terminate flow and are well-suited for applications that need accurate flow regulation, like hydronic heating systems.

It is critical to select the proper valve function to ensure that the valve fulfills the control requirements of the system. Neglecting the function of the valve leads to a regulated system that fails to operate at its maximum potential.

Media type (air, water, steam)

The media variety is another crucial element when choosing a motor-operated valve. The material of the valve must be compatible with the air, water, or vapor that the system transports. A variety of media types need distinct valve materials. For instance, valves utilized in water systems must be corrosion-resistant, whereas valves used in steam systems must withstand high temperatures and pressures.

Incorrect valve material selection may result in leakage, early valve failure, and other complications that cause system failure. As a result, it is critical to determine which valve material is most suitable for the media carried by the system.

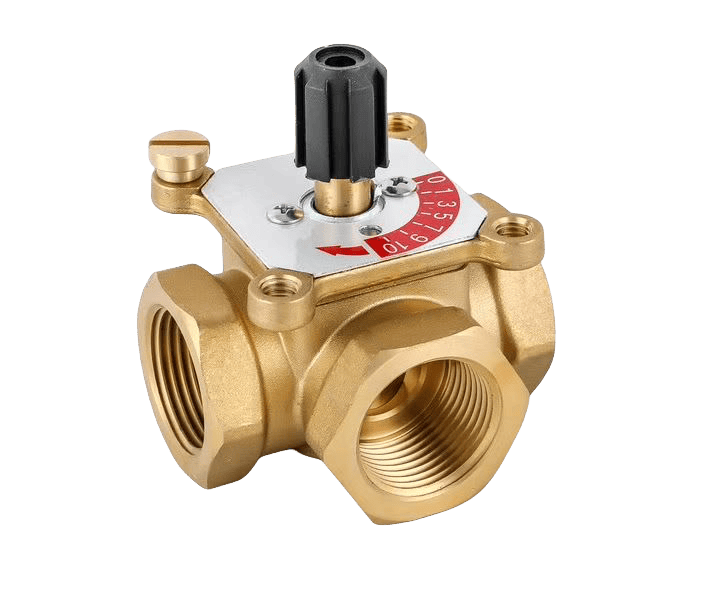

Valve material (brass, bronze, stainless steel)

A vital aspect to note when selecting a motor valve is the valve’s material composition. An assortment of valves are constructed from distinct materials, each possessing unique merits and drawbacks. Brass valves, for instance, are resistant to corrosion and able to withstand high pressures; however, they cannot utilized in corrosive or alkaline environments.

In addition to being corrosion-resistant and suitable for marine environments, bronze valves cannot be utilized in high-temperature applications. Ideal for use in steam systems, stainless steel valves are resistant to corrosion and can sustain high temperatures. Choosing the proper valve material is critical to ensure the valve can endure the system’s needs without early failing.

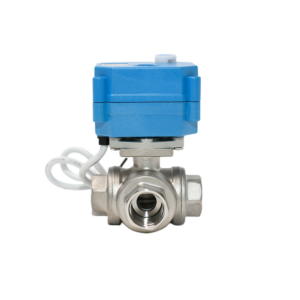

Type of electric valve

A motorized valve actuator price is a form of valve whose opening and closure are controlled by an electric motor. A variety of motorized valves exist, each possessing distinct characteristics and applications. The ball valve is an example of a motorized valve variety. It regulates fluid passage using a rotating spheroid with a perforation at its core. An alternative design is that the gate valve controls fluid flow using a wedge-shaped disk or gate.

The third form is the butterfly valve, which controls the flow with a disc that rotates 90 degrees. These valves are used to regulate the passage of enormous volumes. The globe, diaphragm, and solenoid valves are motorized for precise regulation. Other system requirements, including the controlled fluid, pressure, temperature, and flow rate, determine the type of motorized valve necessary.

Electrical requirements (voltage, current)

Additionally, it is critical to consider the motorized valve’s electrical requirements when selecting. To function, motorized valves necessitate an electrical current; therefore, the voltage and current specifications of the valve must align with the system’s electrical supply. Failure to consider the electrical requirements may lead to a valve that does not operate properly or damage to the system’s electrical components.

To ensure the valve functions at peak efficiency while preventing damage to the system, choosing one that meets the precise voltage and current specifications is critical. To avoid potential complications, adhering to the manufacturer’s instructions during the installation process of motorized valves that may necessitate particular wiring configurations is vital.

Modulating vs On/Off Valves

There are two distinct varieties of electric valves: regulating and on/off valves. The binary operation of on/off valves is entirely closed or open. These units are appropriate for systems in which precise control is not necessary. By altering the position of the valve, regulating valves ensure precise flow control. Therefore, they are ideal for process control and HVAC systems requiring specific flow. Whether regulating valves or on/off valves are utilized will depend on the specifications of the system and the necessary level of control.