Description

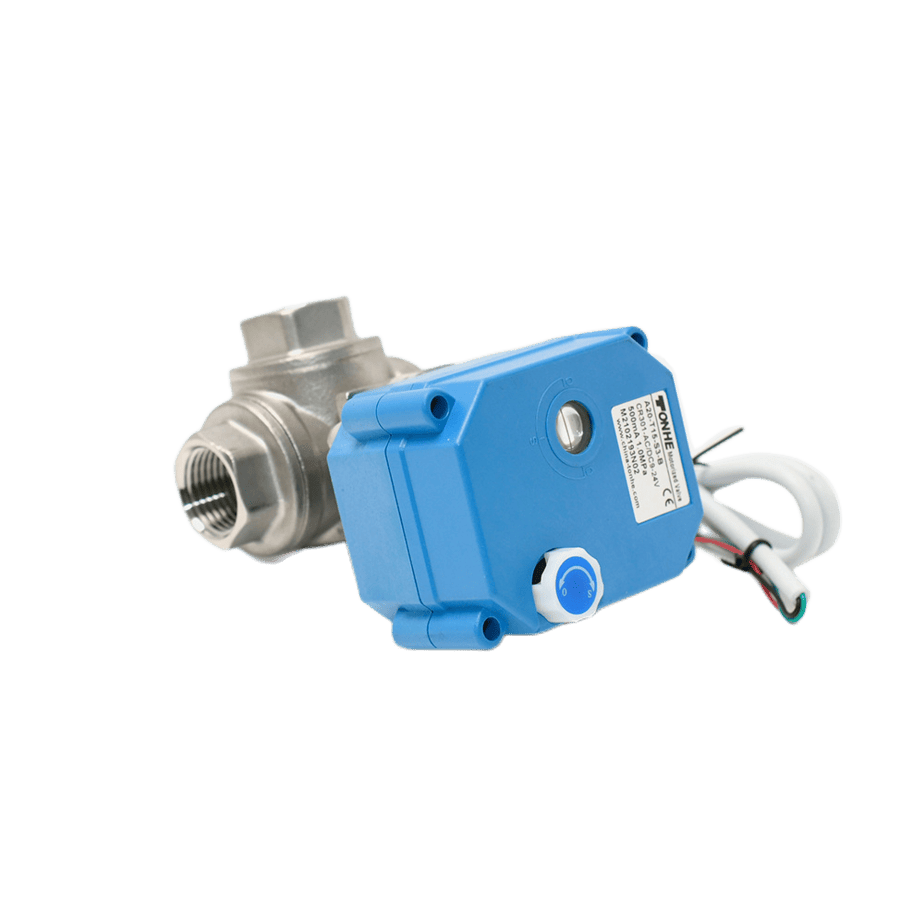

Electric Ball Valve

JX-0304

Valve size: DN15,

Connection: threaded connection (BSPP, NPT)

Valve structure: two-way, three-way

Body pressure: PN20

Operating modes: on or off, or PATDN15 CR201 DC5V

DN15 CR201 DC12/24V

DN15 CR202 AC/DC9-24V

Valve body material; SS304 SS316

Operating temperature;2-90℃

Nominal diameter;12 (mm)

Seal Material; FKM&PTFE

Valve performance characteristics; Good sealing

Working medium; Water, air, other media

Nominal pressure;1.0MPa

Connection method; Thread

Full copper and stainless steel gears are used

What is a DC12 24V actuator Ball Valve?

A DC12 24V actuator Ball Valve is a type of valve used in many industrial, commercial, and residential applications. It is constructed from stainless steel for maximum durability and reliability. The ball within the valve is moved by an electric actuator, allowing for precise control over the fluid flow.

This type of valve requires a DC12 24V power supply, making it suitable for low-voltage systems. It has been designed with corrosion resistance in mind and features a tight seal that prevents leakage or loss of pressure. The valve can be adjusted to regulate the flow of water or other types of liquids quickly and easily. In addition, its anti-jamming design ensures smooth operation even under high-pressure conditions.

Materials and Construction

Materials and construction are two of the most important elements when considering a stainless steel DC12 24V actuator ball valve. The materials used in constructing these valves must be reliable and durable, able to withstand various conditions without losing performance or functionality. High-grade stainless steel is often used for its resistance to corrosion, durability, and ability to maintain a high level of strength while also allowing flexibility. Stainless steel is also an excellent material choice for its low thermal expansion coefficient, which helps ensure the valve can open and close smoothly over time.

The construction process is equally important in determining the quality of a stainless steel DC12 24V actuator ball valve. During production, components must be precisely machined to fit together accurately with no risk of leaking or failing prematurely once installed.

Installation

Installing a stainless steel DC12 24V actuator ball valve can provide a wide range of benefits to any household. The first step in the installation is selecting the right type of valve for your particular application. If you are unsure, speak with an experienced plumbing contractor to help you determine which type of valve best suits your needs. Additionally, when purchasing the valve, purchase all necessary accessories to ensure a successful installation.

When installing the ball valve, ensure it is connected correctly and securely fastened to operate safely and effectively. It’s also important to ensure that no part of the system will come into contact with any moving parts during operation, as this could lead to premature wear or damage. Finally, before using the valve for its intended purpose, test it thoroughly for leaks and other issues that may compromise its functionality.

Advantages of Using a DC12 24V Actuator Ball Valve

Using a DC12 24V Actuator Ball Valve provides several advantages for those who need to use a stainless steel valve for their application. It is specifically designed to be operated using a direct current and is made from the highest quality stainless steel materials, making it resistant to corrosion and wear. The valve is also adjustable and can be used in either an open or closed position, allowing users maximum control over their system operations.

Compared with other valve models, DC12 24V Actuator Ball Valves offer superior performance due to its precision engineering. They are designed with tight sealing capabilities that can withstand extreme temperatures and pressures, ensuring your system’s highest level of safety. Additionally, these valves are lightweight and small, making them ideal for use in confined spaces or where portability is required.

Disadvantages

Stainless steel DC12 24V actuator ball valves are popular in various industries due to their durability and reliability, but some potential downsides should be considered before making a purchase. One of the significant disadvantages is cost; stainless steel is one of the more expensive materials used for valve production. As such, these valves tend to come with a higher price tag than other options. Additionally, although they can be used in various applications, these individual ball valves have limited compatibility due to their specialty nature and may not work with all systems. Furthermore, a part replacement can be difficult due to its custom nature.

Conclusion

This article concludes that stainless steel DC12 24V actuator ball valves are a reliable and efficient option when choosing a valve to control the flow of liquids. They are highly durable and can withstand high temperatures, so that they can be used in many different applications. The DC12 24V actuator ball valves offer superior performance due to their ease of operation, as they can be adjusted using a manual or automated system. Additionally, these valves require minimal maintenance and have a longer lifespan than similar valves. With its robust construction, corrosion resistance, and reliability, the stainless steel DC12 24V actuator ball valve is an excellent choice for any application requiring precise liquid control.

Wiring & Installing Procedure of 230 volt AC valve

An AC actuator has a 3-wire connection & one of them is for neutral. The other two are control wires. It would help if you didn’t connect these wires at a time. It may burn the actuator. Limit switches are there in the actuator. These switches consume energy during the opening or closing of the valve. We should observe the color-coding of the wires always.

230-volt AC valve is an automatic control solution. It is highly preferable to use. Expense & ease of wiring is the issues in this case. There are three wires- blue, brown & black in the actuator. The Blue one is negative or neutral. Black and Brown’s wires are positive. The Black one is for controlling purposes.

Sometimes an electric on-off function may fail. You can run the valve in a manual process. Replacing the faulty actuator is the best solution. It is to open or close the valves manually.

The actuator should be set on top of the valve. It can remove and remount smoothly. Maintenance is also flexible if necessary. Setting up of 24-volt electric valve with an actuator is time-saving.

Valve actuators make watery systems harmless and easier to control. The following issues are necessary to set up an AC valve actuator system:

- We should consider the torque requirements of the system. Fluid viscosity and valve size can affect the torque

- The power source intensity of the actuator installation is accountable

- Valve Mounting Connection will depend on the environment & actuators

- Protection from environmental hazards

- Programmed valve actuators can go into effect if there is any power loss. It may cause by an emergency or system failure.

- Controlling the fluid flow rate is an advantage.

Before installation, we should confirm the valve and actuator are in the same position. An ideal procedure is like below:

- Open the valve in a manual system.

- Install mounting hardware on the valve.

- Once the actuator screws, tighten all nuts and bolts.

- The actuator conduit entry should be in a normal position perpendicular to the pipeline.

- Exclude actuator cover.

- Wire actuator with proper wiring circuit.

- Turn on the power of the actuator.

- Operate the valve to close the port.

- Replace the cover and secure the cover screws.

The motor start capacitor provides enough power in an AC voltage actuator. The energized brake holds the motor in a closed position. Then the actuator can detect the open situation of the valve. It rotates back to the closed position. At that time, power to the actuator motor is cut spontaneously.

The operation of this Valve Actuator is simple. The ball valves need to rotate. This rotation is caused by torque. An accurate torque is a must. The torque comes from the motor. Torque capacity is a vital specification for choosing an actuator. It must be greater than the required torque. It may turn the ball valve into a full close or open state. The Valve Actuator operation depends on the response time. The response time or operation time of an electric actuator is inversely proportional to the torque of the actuator. More torque makes a lower response time.

Applications of 230-volt AC Valve Actuator

AC Actuator is suitable for clean gases and liquids, including cold & hot water. You must be sure the valve is fit for the application. The supplies must be ideal for the medium and the temperature. These AC valve actuators suit petroleum, electric power, water treatment, and shipping. Metallurgy, pharmacy, and chemical industries are using these actuator valves also. The usage is also found in energy, textile, food processing, and other fields. They are used in factory uses associated with manufacturing valves, pumps, and motors. They can automate industrial valves and many types of process plants.

Other fields are:

- Oil and gas plants

- Wastewater treatment plants

- Power plants

- Food and beverage plants

- Farming and agricultural plants

- Pulp and paper plants

- Vacuum & high-pressure applications

- Swimming pool water pipe

- Gaseous, liquid, gelatinous or viscous media