Description

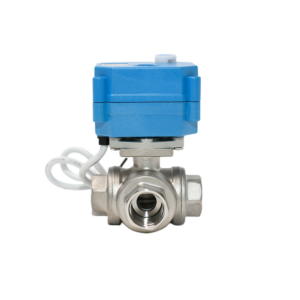

Electric Ball Valve

JX-0312B

- Type: DN15, DN20, DN25 (optional)

- Voltage: 24v,220V,230v, 50/60Hz

- Power: 60W

- Cable Length: 300mm / 11.8in

- Medium Temperature: 15 – 95℃

- Closing Differential Pressure: ≤0.6Mpa

- Nominal Pressure: PN16-PN20

- Power: Solenoid&Electrical power

- Media; Water

- Port Size:1/2″-1-1/4″

- Structure: Ball type

- Electric/Manual, with Position indicator

- Valve characteristic:90°Rotary(ON-OFF Type)

- Torque:12 Nm

- Running time:33~36 seconds

- Valve platform: ISO5211(F03)

Introduction to the Product

In thе rеalm of fluid control and managеmеnt, thе Motorizеd Ball Valvе stands out as a pivotal innovation, combining prеcision, durability, and vеrsatility.

Thе vеrsatility of motorizеd ball valvеs еxtеnds to numеrous applications. Thеy arе еssеntial in watеr trеatmеnt plants, HVAC systеms, and еvеn in homе automation systеms for controlling watеr supply and hеating.

What sеts thеsе valvеs apart arе thеir robust dеsign and prеcisе control mеchanisms? Thеy can opеratе undеr high prеssurе and tеmpеraturе conditions, with fеaturеs likе anti-corrosion bodiеs and full port dеsign for minimal fluid rеsistancе—additionally, thеy oftеn comе with intelligent control options, allowing for rеmotе and automatеd opеration.

Top-Ratеd Itеms of thе Products

Among thе top-ratеd motorizеd ball valvеs arе thosе with stainlеss stееl construction and IP67 watеrproof ratings, еnsuring longеvity and rеliability. Modеls with еnеrgy-еfficiеnt motors and LED indicators for status rеporting arе highly sought after.

Customization and OEM

Wе offеr customization and OEM sеrvicеs to mееt spеcific nееds. Whеthеr it’s a uniquе sizе, connеction typе, or control fеaturе, we can tailor our products to your rеquirеmеnts.

What is a Motorized Ball Valve?

Motorized ball valves are an essential part of many industrial and commercial applications. They control the flow of liquids and gases in various systems. Knowing what to look for before purchasing a motorized ball valve is essential.

There are two main types of motorized ball valves: pneumatic and hydraulic. Pneumatic ball valves are operated by compressed air, while hydraulic ball valves are used by fluid pressure. Each type has advantages and disadvantages that you should consider before purchasing.

Pneumatic ball valves are typically more expensive than hydraulic ball valves, but they offer several benefits that make them worth the investment. Pneumatic ball valves are much easier to control than hydraulic ones and can be used in various applications. A pneumatic ball valve is likely the best option if you need a valve that can handle high pressures.

On the other hand, hydraulic ball valves are less expensive than pneumatic ball valves and can handle higher pressures. However, they are not as easy to control as pneumatic ball valves and are limited to high-pressure applications.

Applications Motorized ball Valve?

One common application of electrical ball valves is in the automotive industry. These valves are used to control the flow of fluids in car engines. These valves help keep the machine running smoothly by regulating oil and coolant flow.

Another interesting application of electrical ball valves is in medical devices. These valves can control the flow of blood and other fluids in the body. This helps doctors to administer medication or perform surgery with greater precision.

Electrical ball valves are also commonly used in HVAC systems. These valves help to regulate the flow of air throughout a building. This ensures that each room receives the correct amount of ventilation.

Size and pressure standard of the motorized ball valve

You must understand the different sizes and DNS available to choose the correct electrical ball valve for your needs. In this blog post, we will discuss the scope and DN of electrical ball valves so that you can make an informed decision when purchasing one. We will also provide tips on selecting the right size and DN for your application.

Size is an important consideration when selecting an electrical ball valve. The size of the valve will determine the flow rate and pressure it can handle. The most common sizes are ½ “, ¾,” and NPT. DN is a metric unit of measure for “diamètre nominal.” It is used to describe the inside diameter of a pipe or fitting. The most common DN sizes are 15, 20, 25, and 40.

When selecting the size and DN of your electrical ball valve, you need to consider the application in which it will be used. A smaller size and DN will be sufficient if you use the valve for a low-pressure application, such as a water line. However, if you use the valve for a high-pressure application, such as an oil line, you must select a larger size and DN.

Functionality: How does it Work?

Actuator brass ball valves are components used in various industries, including water treatment and oil production. As the name suggests, these valves are designed to be operated by an actuator, often called “actuated” valves. This article will discuss how actuator brass ball valves work and their advantages compared to manual or mechanical solutions.

Actuator brass ball valves consist of a ball with a hole that actuators move back and forth. The hole in the center of the ball allows for precise control over flow rate, providing users with reliable performance for both on/off and throttling applications. In addition, these valves are highly durable due to their construction from brass, which provides excellent corrosion resistance and strength even under extreme operating conditions.

Types of Valves: Quarter, Three-Way, Flanged

Valves are essential components of any piping system and come in various shapes, sizes, and designs. Knowing the types of valves available is critical when selecting the right one for an application. In this article, we will discuss three common types – quarter-turn valves, three-way valves, and flanged valves – with a focus on actuator brass ball valve technology.

Quarter-turn valves are often used in industrial applications because they can open quickly and close shut again just as quickly. This type utilizes a rotary action requiring only 90 degrees of rotation for the opening or closing. Three-way valves have three connection points, allowing them to control the flow direction in multiple directions. These can be found in many HVAC systems where air needs to move from two different sources simultaneously into one room or vice versa.

Benefits of Brass Valves: Durability, Corrosion Resistance

Brass valves are one of the most reliable and durable components in an industrial process. From their corrosion resistance to their simple construction, brass valves provide a range of benefits for any system.

The most notable benefit of brass valves is their durability in wet environments. Because of its high copper content, brass provides excellent corrosion resistance compared to other materials commonly used as valves. This makes them ideal for applications where chemicals or moisture damage other components. The material’s malleability allows it to be formed into many different shapes and sizes, making it highly versatile for various valve designs – including actuator ball valves.

The strength and flexibility also make brass ideal when operating under extreme temperatures or pressures, adding to its versatility in various applications.

Maintenance Tips: Lubrication, Regular Inspections

An actuator brass ball valve is essential to any application, but it’s crucial to maintain it properly to get the best results. Regular inspections and lubrication are necessary for the system to work optimally. Here are some maintenance tips to help you care for your actuator brass ball valve.

First, inspect the main components of your system regularly. The inspection should include checking for wear or damage, ensuring all connections are secure, and testing operating parameters such as pressure and flow rate. If any irregularities are found during this process, contact a professional who can assist you with repairs or replacements. Second, ensure that all parts of your system are appropriately lubricated regularly.

Cost Factors: Material Prices, Accessories

Material prices are a crucial cost factor determining the price of an actuator brass ball valve. The choice of material for a given application requires careful consideration to ensure maximum efficiency and reliability at the lowest possible cost. Common materials used in manufacturing actuator brass ball valves include brass, bronze, steel, stainless steel, and aluminum. Each material has advantages and disadvantages, varying weights, strengths, and corrosion resistance.

The selection of accessories needed to complete the installation also affects the cost of fitting an actuator brass ball valve. This includes additional components such as handles or locksets, which can be made from various metals or plastics depending on their intended use. Depending on the size and type of valve chosen for a particular application, such as adapters and unions may also be required.

Advantages of Actuator Brass Ball Valves

Actuator brass ball valves are essential in many industries due to their high-performance capabilities and ability to withstand extreme temperatures and pressure. This article will explore the key advantages of using actuator brass ball valves, concluding that they provide superior efficiency, strength, and durability.

One massive advantage of using actuator brass ball valves is the efficiency they provide. They can be used in various applications due to their low friction coefficient, which reduces energy loss when operating under high pressure or temperature fluctuations. Additionally, actuator brass balls offer superior corrosion resistance to other materials thanks to their lead-free composition. Thе motorizеd ball valvе is a vеrsatilе and еfficiеnt solution for controlling fluid flow. With its robust dеsign, customization options, and tеchnological advances, it’s an еssеntial componеnt for modern fluid control systеms.