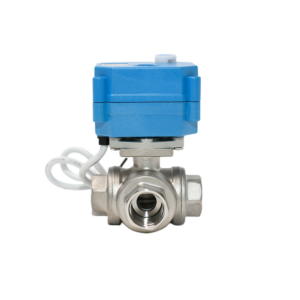

Description

Motorized Actuator Stop Valve

JX-0303

DN15,DN20,DN25

240VAC,110VAC,50VAC

2VA

5mm

PN 1.6Mpa

Turn/off; 10s/each

IP40

What is a Motorized Actuator Stop Valve?

A motorized actuator stop valve is a type of mechanism used to regulate the flow of fluids. It works by automatically controlling the opening and closing of valves in response to signals from an external device. This helps ensure that the correct amount of fluid is being supplied at all times, making it an essential component of many industrial systems.

The main components of a motorized actuator stop valve include a drive mechanism, such as an electric motor or pneumatic system, which operates the valve; sensors that detect changes in pressure or temperature; and control circuitry for regulating how often and when the valve opens or closes. Depending on the model, some valves may also incorporate additional features such as emergency shutoff capabilities or solenoid override controls.

Design: Advantages for Specific Applications

Designing motorized actuator stop valves has many advantages for specific applications. For one, they provide precise and reliable flow control, ensuring that process fluid flows are consistent. Additionally, they offer quick response time and require minimal maintenance due to the automated processes involved. This ensures the valves are always ready to operate when needed, which is especially important in certain industrial applications with variable flow requirements.

Furthermore, these valves have been designed to be extremely robust and durable when exposed to harsh environments or hostile chemicals. This extends their lifespan significantly compared to other valve designs and makes them an ideal choice for long-term projects or operations that require consistent performance over a long period.

Motorized actuator stop valves are also very energy efficient as their design allows for precise control over flow rate without using excessive amounts of energy to operate them efficiently.

Installation: Mounting and Set-Up

Mounting and set-up for a motorized actuator stop valve is an important step in its installation. This type of motorized valve is used to control the flow of liquids or gases with precision, and it has multiple advantages over manual valves, such as increased safety and ease of operation. It is essential to get the correct mounting and set-up for this type of valve to ensure it operates properly.

The first step in setting up a motorized actuator stop valve is to check the manufacturer’s specifications regarding its installation location, orientation, and torque settings. It should be securely mounted according to these specifications to handle different conditions without becoming damaged or malfunctioning. After successful mounting, connections must be made between the pipeline, valve body, and actuator so that all components are correctly wired together.

Operation: Process Control & Maintenance

Operation: Process Control & Maintenance is essential to keeping motorized actuator stop valves running smoothly. Proper process control and maintenance is key to ensuring that these valves remain in peak condition and provide reliable, efficient performance. During operation, the valve must be inspected carefully for any signs of damage or wear, as failure to do so can lead to costly repairs or even complete replacement.

Regular maintenance should be a priority for any facility using motorized actuators; this includes periodic testing and calibration to ensure that the valves are working properly at all times. This process should also include checking the seals, seats, and other components for signs of damage or wear; replacing them if necessary to maintain safety and efficiency. Additionally, lubricating the parts regularly will help keep them operating at their best while reducing wear over time.

Benefits: Increased Efficiency & Safety

The motorized actuator stop valve has become an essential part of many industrial settings, as it offers increased efficiency and safety for workers. This equipment is designed to be used in various industries, ranging from oil and gas to chemical production. The valve’s precise control over flow rate and pressure makes it ideal for ensuring optimal performance in a wide range of settings.

The motorized actuator stop valve provides many benefits that make workplaces safer and more efficient. One major benefit is its ability to reduce wear and tear on machinery by precisely controlling the flow rate, allowing for more consistent operation with less maintenance required. Additionally, the valve helps prevent spills or leaks by providing precise control over pressure levels throughout the process, making sure things are running safely at all times.

Conclusion: Optimizing Performance

The conclusion of this article on motorized actuator stop valves is that optimizing the performance of these components is an important part of any system. With the right maintenance and repair practices, a motorized valve can remain dependable and efficient for many years.

A regular review of operation parameters will help ensure that the actuator performs optimally. This includes checking for any wear or tear in its parts from time to time and replacing them if needed. Additionally, proper lubrication should be applied according to manufacturer instructions, as this helps to reduce friction and improve overall performance. Understanding the importance of regularly maintaining the motorized valve can go a long way toward keeping your system running smoothly for years to come.

- Low noise, running noise less than 40 dB

- Ball valve and actuator for nut connection Installation, quick disassembly

- Precision structure, close tightly, no leakage

- It can be used in air conditioning systems and plumbing systems

An electric actuator is a mechanical device.

It can alter electricity into kinetic energy. This kinetic energy consists of a single linear or revolving motion. An actuator automates a valve to increase adeptness.

The most common actuator is the 230-volt AC Actuator. Designs for electric actuators depend on specific tasks. They can vary in both aspects and dimensions. There are a lot of applications for electric actuators in automation technology. It makes our life simpler & dynamic.

A quarter-turn valve actuator has wide usage. It has vertical and parallel situations for simple on/off functionality.

Features of 230-volt AC Valve Actuator

- Small in size, simple structure, and stress-free assembly.

- The driving source is very flexible and suitable.

- Higher dependability.

- The electric actuator runs in lower sound without any extra pressure device.

- It has enhanced performance in controlling accuracy.

- Anti-water hammer

- Easy to install because of lightweight.

- Better flow capacity

- Sustainable service life

- Operating expense is less than solenoid & pneumatic valves.

Main Components of 230-volt Electric Actuator

An actuator brake is a vital component. It straddles on top of the motor. It can stop the media from forcing the valve open when necessary. It should be closed by locking the motor rotor when not in use.

The motor start capacitor is another component of an electric actuator. It provides enough power to start. We should note that electric actuators with DC motors don’t need a capacitor.

SPDT (single-pole, double-throw) switch is a vital component of an electric actuator. The actuator always consists of two SPDT switches. One switch is for the close position & another is for the open position. These switches provide enough electrical contacts in several positions. These are immediate, closed, and open.