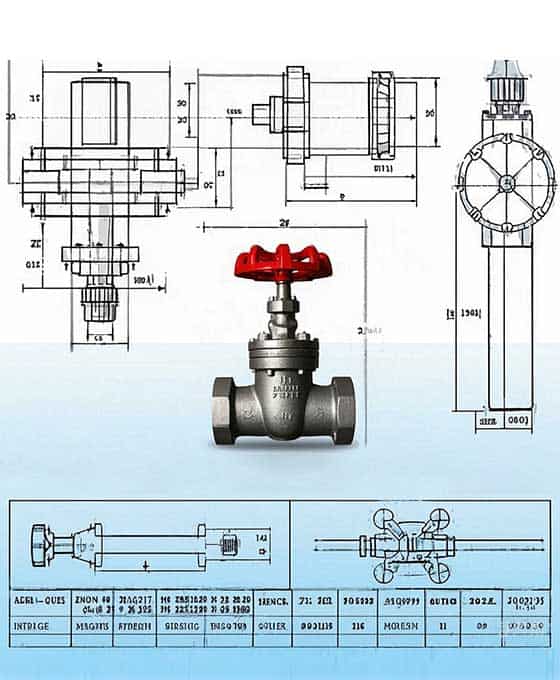

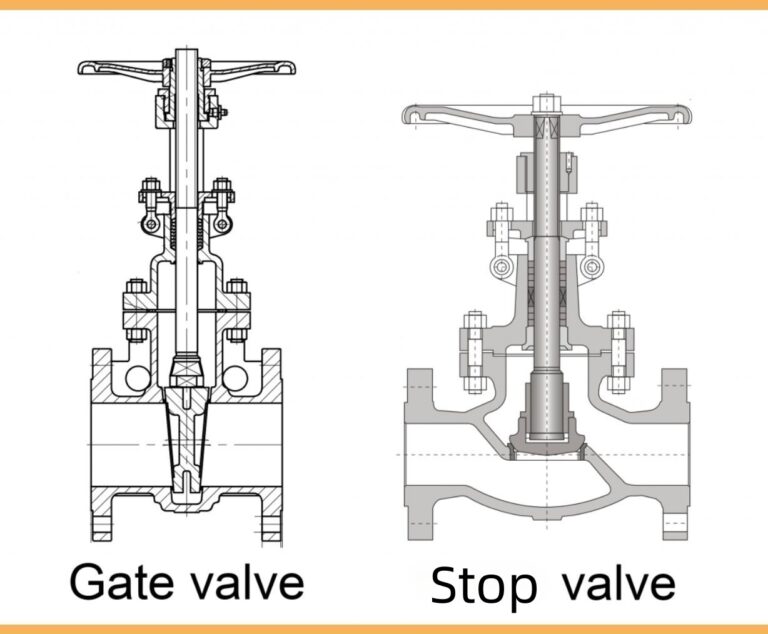

Stop Valve Vs. Gate Valve: What’s The Difference

Gate valves and stop valves play crucial roles in regulating liquid and gas flow in piping systems. Gate valves are ideal for high-pressure applications, offering strong seals and less maintenance, while stop valves are more suited for low-pressure, quick shut-off needs. Consider factors like functionality, pressure, maintenance, and cost to choose the best valve for your system.