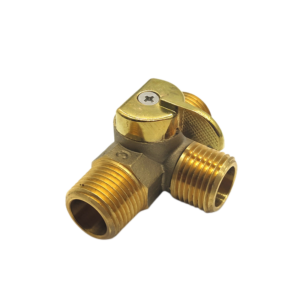

3-way Plug Ball Valve With Lead-free Brass

End the hassle of replacing corroded valves

Replacing corroded valves can be a hassle. The process of removing the old valve and installing the new one can be time-consuming and difficult. But there is a new valve available that makes the process easier. The Wedge-Lok valve is designed to replace corroded valves without having to remove the entire valve assembly.