Description

Electric Ball Valve

JX-0302

- Drive power: 220VAC, 50-60HZ (can be customized 24V AC), DC24V

- Power: 6 W

- Action time: 15 S

- Lead length: 50 cm (can be customized)

- Medium: cold/hot water

- Medium temperature: 2 ℃ -95 ℃

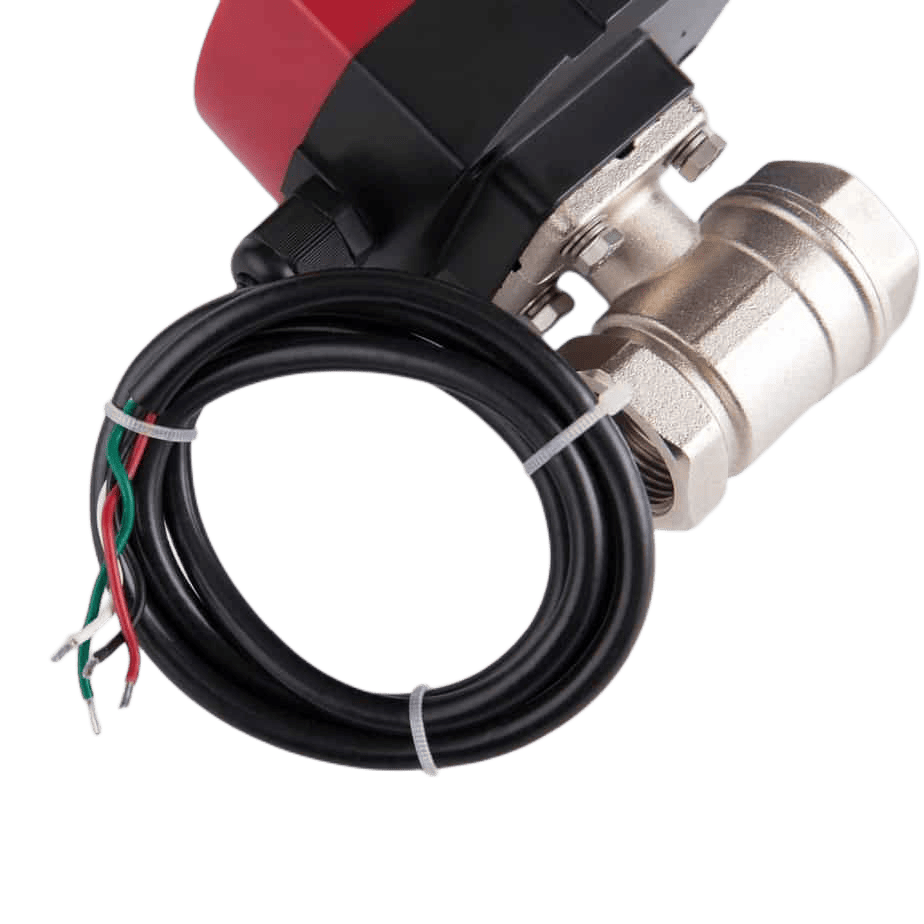

- Control: three-wire two control (can be customized three-line control)

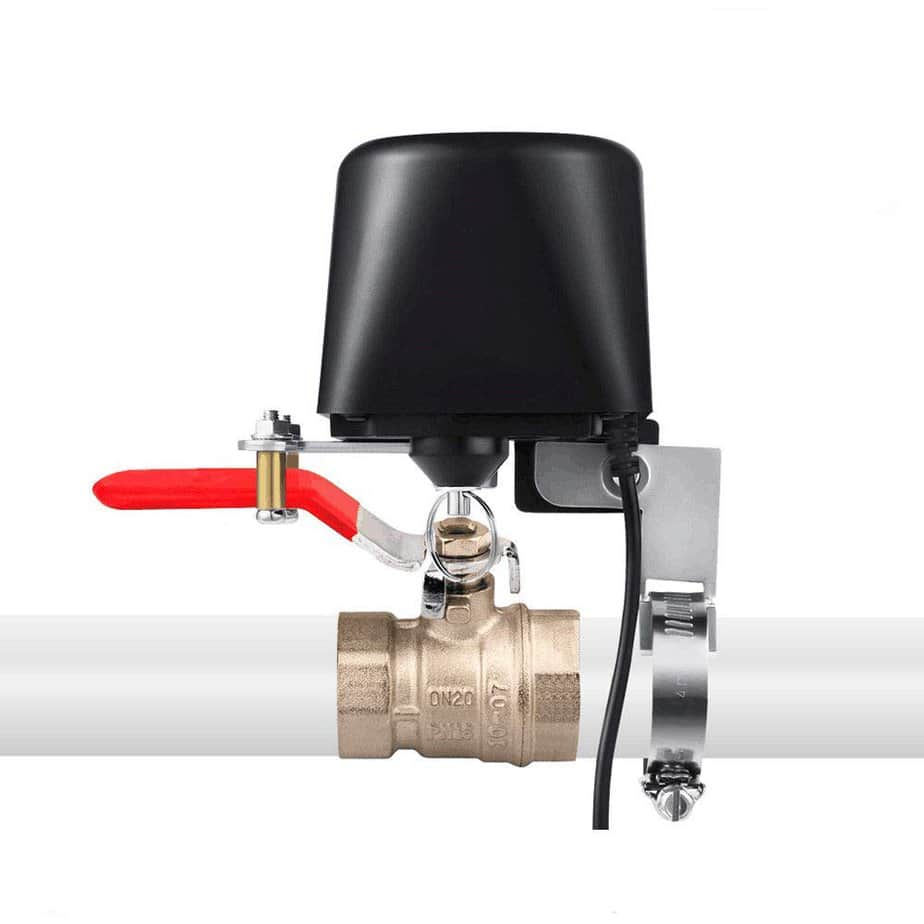

- It is suitable for HVAC and status control of the water system. The valve body adopts the ISO228 standard platform, and the actuator uses a synchronous machine that drives the gears steadily. The new product is to meet customers’ requirements with compact size, ample torque, simple operation, free maintenance, and convenient installation under different working conditions. In addition, the actuator is equipped with a manual handle to open or close the valve in case of a power cut or other emergency.

- DC 24V

With an electric auxiliary switching valve function

Power consumption; 6W, running time; 5-15 seconds

Maximum differential pressure: 1.0Mpa

Low noise, operation noise less than 40DB;

The ball valve and the actuator are threaded following the way, quick disassembly.

Suitable for water or ethylene glycol with a concentration of less than 60%

Fluid temperature 2-94 °C degrees, storage temperature -20-65 °C.

Working pressure PN 1.6Mpa

The valve body is brass

Three lines, two control

High temperature resistant

One particular star in this realm is the Electric Ball Valve. As the name suggests, it’s not just your average ball valve; it’s powered by electricity. But what exactly does that mean? Let’s get into the specifics.

Introduction to Electric Ball Valves:

An electric ball valve is a ball valve controlled by an electric actuator. The actuator will rotate the ball, typically 90 degrees, to open or close the valve. This is in contrast to manual ball valves, which require someone to turn the valve physically, or pneumatic ball valves, which use air to actuate the valve.

Sizes of Electric Ball Valves:

Electric ball valves come in various sizes, depending on their intended application:

- Micro-sized Valves: These are often 1/8″ to 1/4″. They’re perfect for small-scale operations, often found in labs or intricate machinery.

- Small to Medium-sized Valves: Ranging from 1/2″ to 2″, these are commonly used in residential plumbing, smaller industrial applications, and HVAC systems.

- Large-sized Valves: 3″ to 8″ and above. These valves are deployed in large-scale industrial processes, municipal water systems, and in sectors like petrochemicals.

Key Specifications:

- Material: The valve’s construction material dictates its strength, longevity, and compatibility. Common materials include:

- Brass: Suitable for non-corrosive mediums.

- Stainless Steel: Apt for corrosive environments and offers enhanced durability.

- PVC: Great for water systems and some chemical processes due to its corrosion resistance.

- Voltage Requirements: Ensure the electric actuator’s voltage aligns with your supply voltage. Common voltages include 12V, 24V, 110V, or 220V.

- Torque: Measured in Newton meters (Nm) or foot-pounds (ft-lb), it indicates the force exerted by the actuator to rotate the valve. A larger valve or one expecting more resistance (due to high flow rates or viscous mediums) will require a higher torque.

- Temperature Range: Electric ball valves can operate within specific temperature ranges depending on the material and design. For instance:

- Brass: -20°C to +200°C

- Stainless Steel: -270°C to +400°C

- PVC: 0°C to +60°C

- Pressure Rating: Dictates the maximum pressure the valve can handle without compromising integrity. Common ratings are often in PSI (Pounds per Square Inch) or Bar. For example:

- Brass: Up to 600 PSI

- Stainless Steel: Up to 1000 PSI

- PVC: Up to 150 PSI

- Actuation Speed: How quickly the valve can transition from the open to the closed position, often measured in seconds.

- Connection Type: Refers to how the valve attaches to the piping. Common types include threaded (NPT or BSP), flanged, or push-fit.

- Seal Material: Ensures the valve is leak-proof. Common materials include PTFE (Teflon), EPDM rubber, or Viton, each having specific temperature and chemical compatibility ranges.

Understanding sizes and specifications is critical when choosing an electric ball valve. The right choice will ensure efficient operation, a longer lifespan, and fewer maintenance issues. Always refer to manufacturer datasheets and consult with experts if unsure of your specific needs.

Raw Materials in Electric Ball Valves:

The bedrock of any device’s performance, durability, and safety is fundamentally rooted in its raw materials. Electric ball valves, integral components in many fluid flow systems, are no different. Understanding the materials that form these valves gives one a clearer insight into their capabilities and ideal applications. Here’s an original overview of the primary raw materials used in electric ball valves:

1. Brass:

- Source: An alloy of copper and zinc, brass’s golden hue isn’t its only advantage.

- Properties: Exhibits excellent machinability, making it a favorite for manufacturing. With good corrosion resistance, especially against water, it’s a common material for plumbing applications.

- Limitations: Not suitable for highly corrosive environments or high-temperature applications.

2. Stainless Steel:

- Source: Primarily composed of iron, chromium, nickel, and carbon inclusions.

- Properties: Highly corrosion-resistant, especially the 316 variant, which includes molybdenum for enhanced resistance against chlorides. Offers strength and durability.

- Limitations: Despite its robust nature, it can be more costly and unsuitable for specific chemicals.

3. PVC (Polyvinyl Chloride):

- Source: A synthetic plastic polymer, white in its original state.

- Properties: Lightweight, corrosion-resistant, and suitable for water and some chemical processes.

- Limitations: Not ideal for high-temperature applications and can degrade when exposed to certain organic solvents.

4. Zinc:

- Source: A naturally occurring metal, often alloyed with other materials to improve their properties.

- Properties: When alloyed with copper to produce brass, it strengthens and maintains flexibility. Sometimes used as a coating (galvanization) for steel to provide corrosion resistance.

- Limitations: Pure zinc isn’t typically used for valve bodies as it can corrode in specific environments.

5. Aluminum:

- Source: A silver-white, lightweight metal abundant in the earth’s crust.

- Properties: Lightweight, corrosion-resistant, and possesses good thermal and electrical conductivity.

- Limitations: While it’s resistant to rust, it can corrode in highly alkaline or acidic environments.

6. Seals and Gaskets:

Materials like PTFE (Teflon), EPDM rubber, and Viton are often used to ensure leak-proof valves. Their selection depends on the valve’s intended application and the medium it will regulate.

The raw materials utilized in electric ball valves significantly dictate their functionality and longevity. Users can ensure optimal performance in specific environments by choosing a valve made from suitable materials, reducing wear, maintenance, and potential downtime. Always research and, if needed, consult experts before making material-based decisions.

OPERATING PRINCIPLE OF MOTORIZED BALL VALVE

This type of electric ball valve operation is not so complicated. The primary function is to rotate the ball valves by torque. The electric motor of the valve produces torque. This torque is then transferred by a shaft connected to the valve stem. It makes the ball valve rotate. In this case, a precise & enough torque must be generated. Having a gearing system is good for the proper torque. This gearing system connects with the electric motor shaft.

Another vital thing is torque capacity. It’s an essential specification for choosing an actuator. Torque capacity must be greater than the required torque, and it’s a breakaway one. The breakaway torque is the least. Turning the ball valve into a full close or a fully open state is necessary. It will help to turn the ball valve by a certain percentage. Valve manufacturers make it specific all the time.

The whole operation depends on the response time of an actuator. From the technical point of view, you can call the speed of the process response time. The response time or operation time of an electric actuator is inversely proportional to the torque of the actuator. The gear system describes the relationship between speed and torque, and A higher gear ratio makes more torque. More torque makes a lower response time.

Actuators are comfortable with 12V, 24V, and 48V direct currents. If alternating current, the voltage value will be 24V, 48V, 120V, 130V, and 240V. You can use a limit switch to control the wind. It will stop the current when the valve is fully closed or open. Sometimes, there needs to be a modulating control. Motors can carry out the power of modulation. This can fix the position of the valve. Modulation control makes the situation easier at any point between opening and closing. It means the work is between 0° and 90°. This is useful for a valve. It can regulate the flow rate through the valve. You can also use a positioning circuit board in the actuator. It helps to modulate the electric motor.

MOTORIZED BALL VALVES FOR HVAC APPLICATIONS

Two distinct types of rotary actuators are available for HVAC application. Among them, one is the basic start/stop unit. This unit defines that the valve is either in a fully open or a whole closed state. Another type of actuator makes position between 0 and 90° using a control signal. And it’s because of modulating control. Which operation is slower. It makes perfect flow control for HVAC applications. The flow optimizer makes the flow rate increase. It works in direct proportion to the rotation of the ball.

Monitoring the percentage of flow is essential. The rate of flow changes with the optimizer disc variation as the ball rotates. A valve without the optimizer causes a sudden increase in the flow. This precise control is helpful for applications like mixing water on heat exchangers.

Replacing the actuator is very crucial for HVAC applications. First, ensure the actuator drive tab and the valve stem slot are in the same orientation. If not, you should rotate the valve stem with a screwdriver to align it. After that, press the actuator onto the valve stem. Then, swap the locking pin on either side.

ADVANTAGES OF USING MOTORIZED BALL VALVE

- Low resistance with the medium

- Easy for installation and transport because of lightweight and small-volume components

- Environmentally friendly and non-toxic. So that pure water and drinking water flow system is convenient.

- Greater flow capacity

- Reasonable price

- Sustainable service life.

- Greater Cv (molar heat capacity at constant volume) value than solenoid valves

- Automated systems

- Operating cost is less than solenoid valves

- Anti-water hammer

- Automated systems

- Operating cost is less than solenoid valves

- Anti-water hammer

How to Install and Repair an Electric Ball Valve: A Comprehensive Guide

Electric ball valves are integral to various systems, from home automation to large industrial processes. Proper installation is paramount to ensure optimal performance, and knowing how to repair one can save costs. Here’s a comprehensive guide:

Installation of Electric Ball Valve:

1. Pre-Installation:

- Safety First: Always turn off the electricity and shut off the main water or gas supply.

- Inspect the Valve: Inspect the valve for any visible damage or defects before installation.

- Gather Necessary Tools: Wrenches, Teflon tape, electrical wire, wire stripper, and screwdrivers are typically required.

2. Positioning:

- Determine the flow direction. Most valves will have an arrow indicating the flow direction.

- Ensure the area is clean from debris which could damage the valve.

3. Plumbing Connection:

- Use Teflon tape on threaded connections to ensure a leak-free joint.

- Align the valve with the pipe ends and tighten using a wrench. Avoid over-tightening, which could damage the threads.

4. Electrical Connection:

- Expose the electrical terminals by removing the protective cover.

- Connect the wires using the valve’s manual or labeling as a guide. Typically, there’s a standard wire, a wire to open the valve, and another to close it.

- Secure connections with wire nuts and ensure no exposed wires are visible.

- Replace the protective cover.

5. Testing:

- Turn on the water or gas supply slowly and check for leaks around the valve connections.

- Energize the valve, ensuring it opens and closes as expected.

Repair of Electric Ball Valve:

1. Diagnosis:

- Identify the issue: Is it a mechanical fault with the valve not opening/closing or an electrical issue with the actuator?

- Listen for any unusual sounds when the valve operates.

2. Mechanical Issues:

- Leakage: Often due to worn seals. Turn off the supply, disassemble the valve, and replace the seals or gaskets.

- Stiff Movement: This can be due to debris buildup or corrosion. Clean the valve, removing any obstructions.

3. Electrical Issues:

- Actuator Not Working: Use a multimeter to check if power reaches the actuator. If not, the issue might be with the wiring or power source.

- Incomplete Operation: This might be due to a misalignment of gears inside the actuator. Open the actuator housing and inspect for any visible damage. Realign or replace components as necessary.

4. Replacement:

- If repairs are extensive or the valve is old, replacing the entire unit might be more cost-effective.

- To replace, turn off the supply, remove the old valve, and install a new one following the above installation steps.

Conclusion:

Regular maintenance, such as cleaning and periodically testing the electric ball valve’s operation, can prolong its life and reduce the need for repairs. Always refer to the manufacturer’s manual specific to your valve model for any nuances in installation or repair procedures.