Top 8 brass fittings manufacturers in South Africa

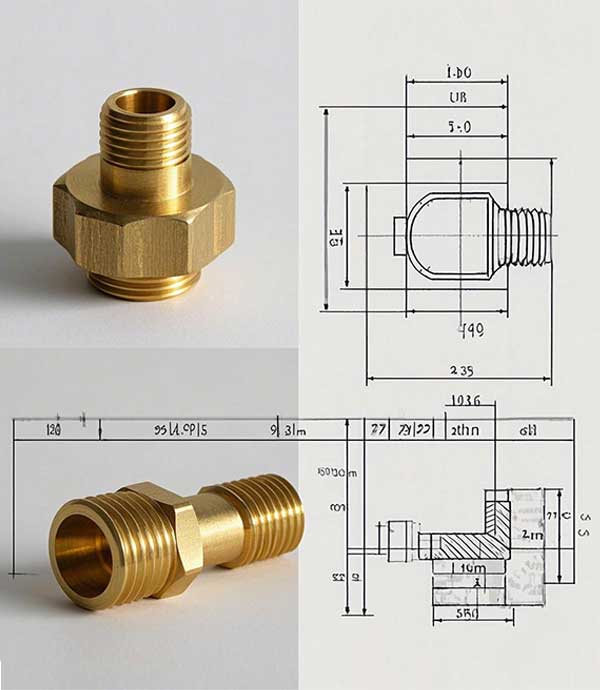

Brass fittings, known for their durability and resistance to corrosion, are a premium choice in plumbing systems. South Africa hosts top brass fitting manufacturers, including ZAJF Enterprises and Casa De Bronze, offering high-quality products across plumbing, industrial, and automotive applications. Their reliable fittings ensure optimal performance for heavy-duty projects.