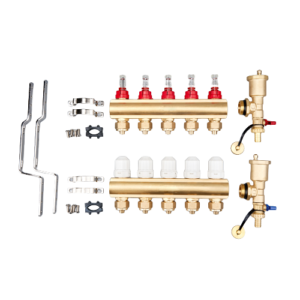

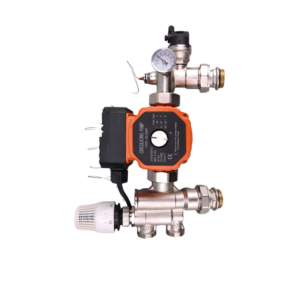

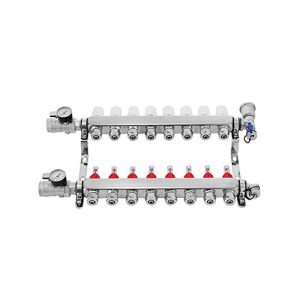

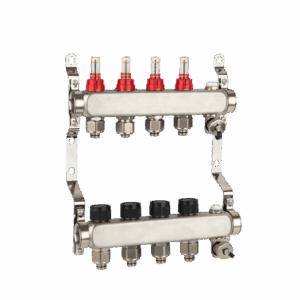

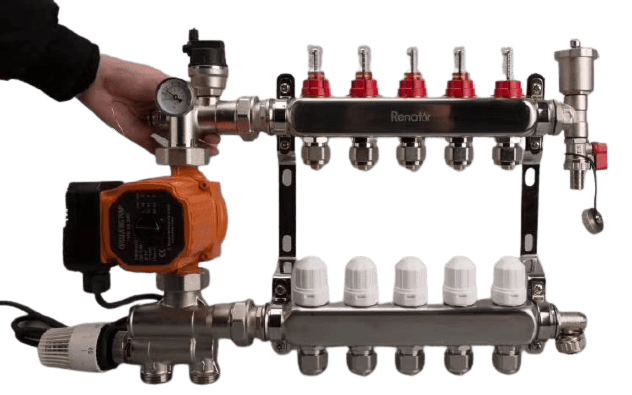

Exclusive Range of PEX Manifolds at Plumberstar

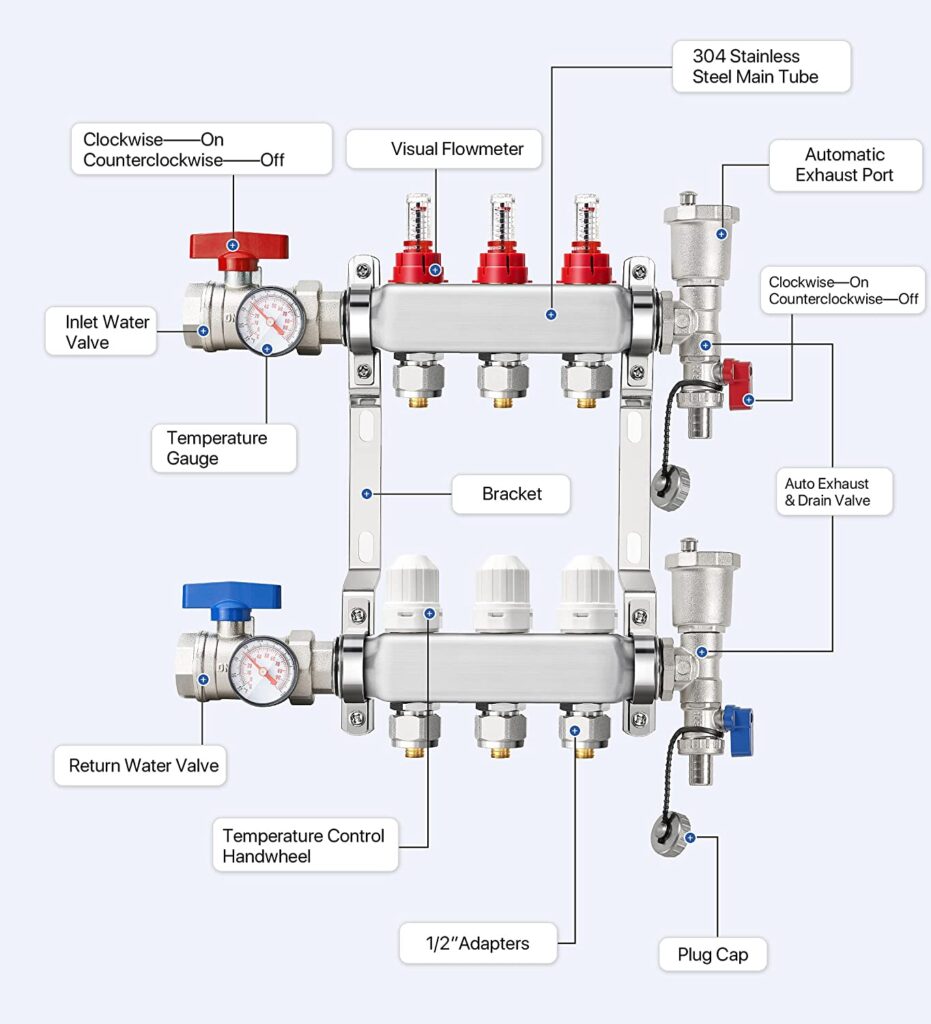

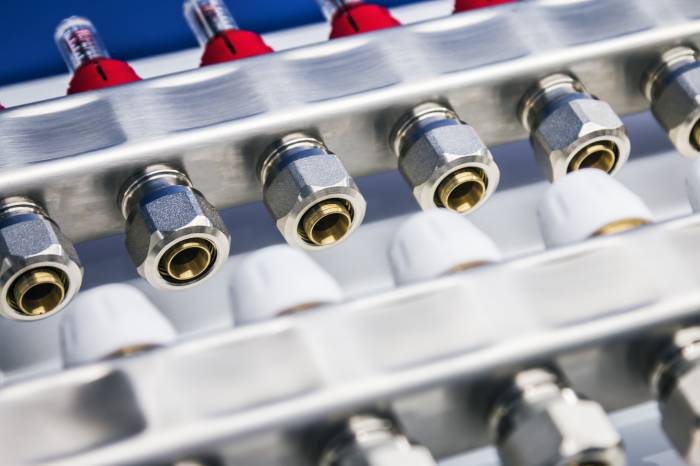

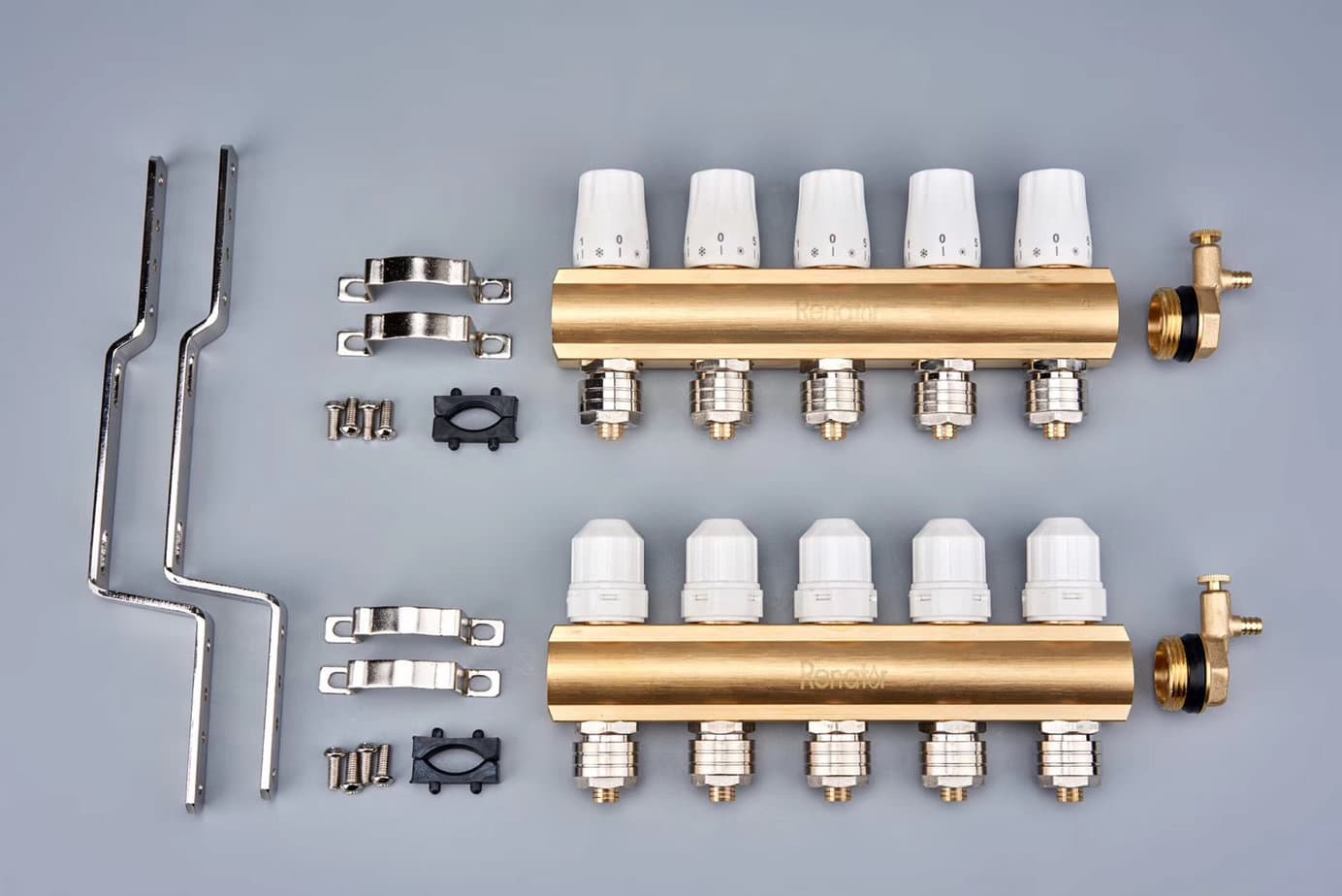

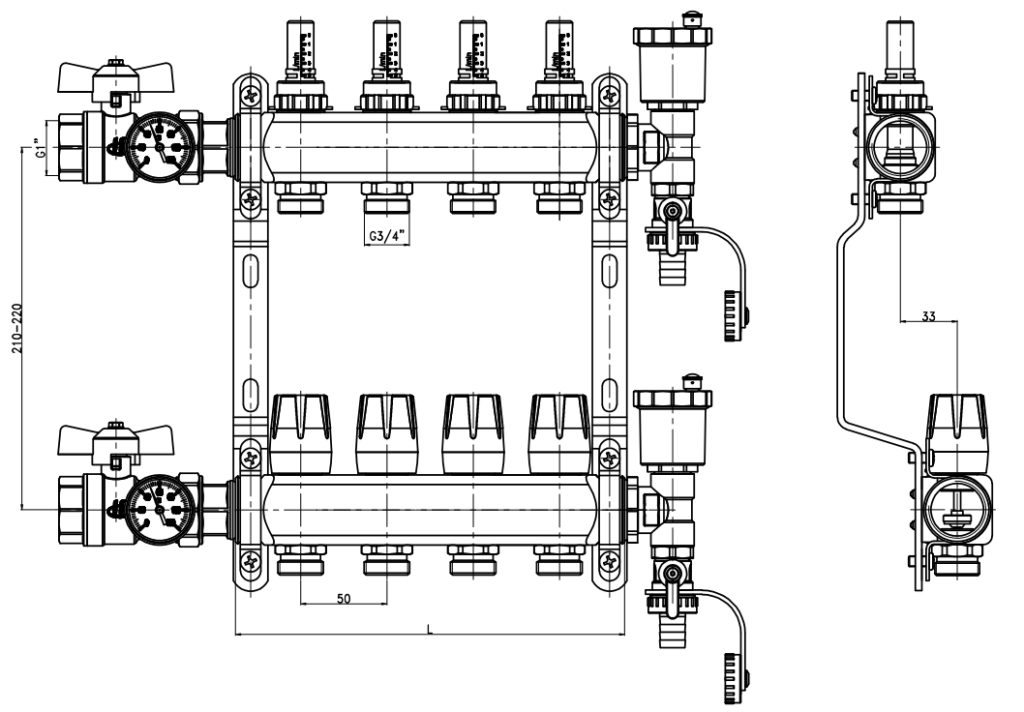

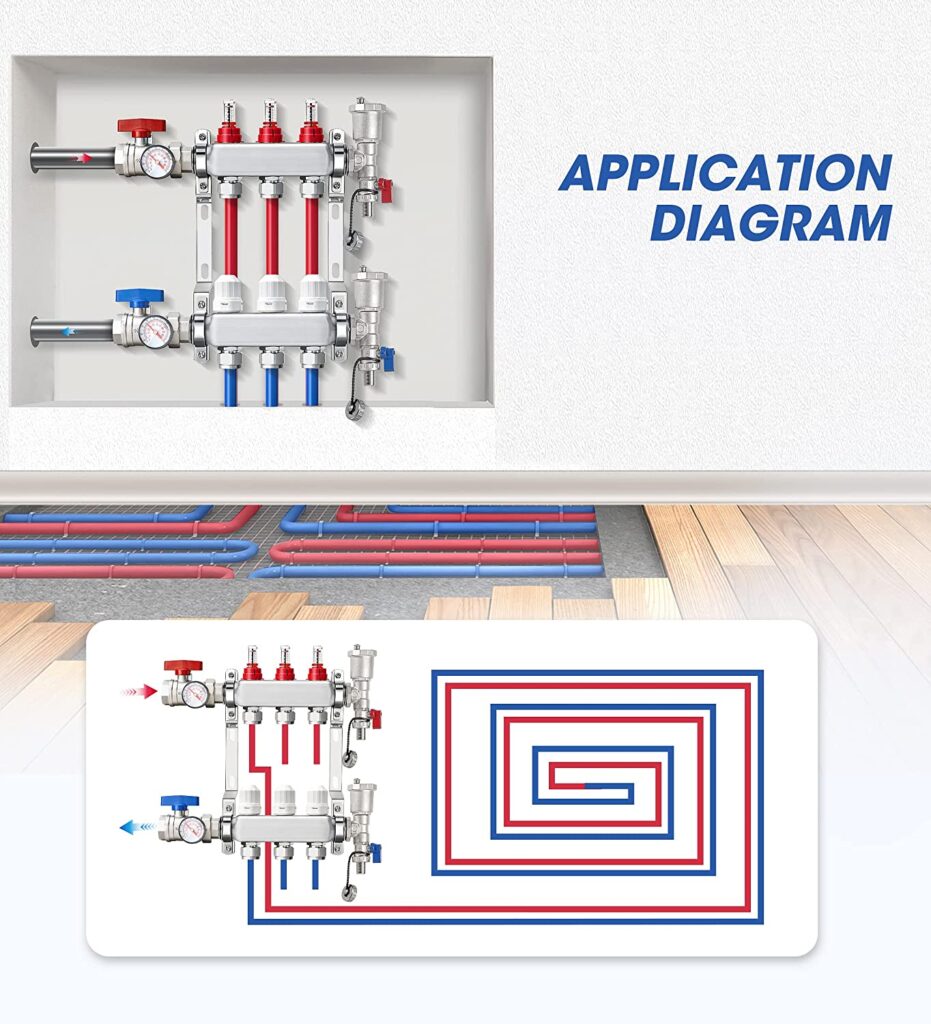

Manifolds form the heart of an underfloor heating system. They play the most crucial role in working underfloor heating systems. At Plumberstar, you get an exclusive range of PEX manifolds. Our underfloor heating manifolds are highly durable and long-lasting. With unique features, our PEX heating solutions are ideal for your demands. Our expert team is keenly aware of the rapid evolution. Thus, we continuously upgrade the products. As PEX manifold manufacturers, we provide our customers with professional assistance. Explore our premium product range and contact us to reach the inner circle.