Description

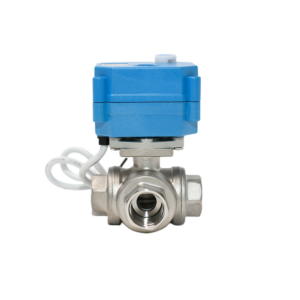

Actuator Brass Ball Valve

JX-0320

DN25 two-way external wire

DN20 two-way internal thread

DN20 two-way inner wire

DN25 two-way internal thread

DN25 two-way inner wire

DN20 tee outer thread

DN20 tee outer wire

DN25 tee outer thread

DN25 tee outer wire

DN20 tee internal thread

DN20 tee inner wire

DN25 tee internal thread

DN25 tee inner wire

DN20 two-way external wire

PN;1.6Mpa; brass, copper

What is a Motorized Ball Valve?

This ball valve features an electrical actuator, allowing easy valve opening and closing. Valves are used in plumbing, air conditioning, refrigeration, and heating systems, and they play an important role in fluid flow circuits. Most valves only need to be manually actuated to open and close. However, some particular scenarios require automatic actuation, such as air-conditioning systems, refrigeration, heating, industrial pipelines that are not convenient, or other remote and dangerous toxic environments; if you use an electric ball valve, you can solve this problem. The function of motorized ball valves is the same as that of manual ball valves, which are only driven by a motor—remote automatic opening or closing.

Motorized valves have an extensive range of applications; refrigeration and heating, water piping, gas piping, agricultural irrigation, commercial construction, industrial piping, aircraft de-icing, and automatic fire suppression are some of the uses that can benefit from these valves. There is no difference between the fluid of a motorized ball valve and a manual ball valve; the only difference is how the valve is actuated.

Applications Motorized ball Valve?

The actuator ball valve is the perfect choice for controlling the flow of water, gas, or other fluid media in a piping system. It features an electric actuator that provides precise and reliable valve control. The brass construction makes it durable and corrosion-resistant. It also has a spring-return mechanism that ensures quick and easy operation. This ball valve is ideal for residential, commercial, and industrial applications.

The actuator ball valve is perfect for controlling the flow of water, gas, or other liquid substances. The valve has a brass construction and a chrome-plated finish, making it durable and easy to clean. It also features an electrical actuator that easily opens and closes the valve. This is an excellent choice for those looking for an efficient and reliable way to control the flow of substances in their home or wholesale markets.

Overview of Actuator Brass Ball Valve

An actuator brass ball valve is a device used to control fluid or gas flow. It consists of a ball-shaped disc between two concentric rings, which can be opened or closed by turning the handle attached to the stem. When the handle is turned, it moves the stem, which rotates the partially open or fully closed ball-shaped disc. This type of valve has many advantages over other valves, including durability, ease of installation and maintenance, and corrosion resistance.

Actuator brass ball valves are widely used in residential water systems, commercial buildings, and industrial applications due to their reliable performance under varying conditions. They can also regulate the temperature in HVAC systems as they have tight shutoff capabilities with low leakage rates compared to other valves.

Materials Used

When it comes to the construction of an actuator brass ball valve, quality is key. This type of valve requires durable and reliable components to ensure its long-term effectiveness. The material used in the construction of this device matters, as it must withstand high pressures and maintain a tight seal over time.

Common materials used for this type of valve include brass and stainless steel, which have proven highly durable and reliable. Brass provides high corrosion resistance, making it ideal for use in environments with high moisture levels or acidic conditions. Stainless steel offers superior strength and corrosion resistance compared to brass, making it suitable for more extreme applications where temperatures are higher than usual.

Advantages: Benefits of Using

Actuator brass ball valves are most commonly used in many industrial settings. These valves provide advantages over other valves, making them an ideal choice for many applications. The benefits of using actuator brass ball valves include easy installation, durability, and reliable operation.

One advantage to using actuator brass ball valves is their ease of installation. Since they have few moving parts, they can be quickly installed with minimal effort compared to other valve types. This allows for greater flexibility when installing the valve in any system or application. Additionally, it requires fewer tools and materials than different valves, making it more cost-effective.

Operation: How It Works

An actuator brass ball valve is the most common type of valve used in industry today. It consists of a body, handles, and a round or ball-shaped part that can rotate within the housing. When the handle is turned, it moves the ball to either open or close off the flow of material through the valve.

The first component of an actuator brass ball valve is a hollow body with two openings that connect to pipes or other equipment. Inside this body are two opposed seats where a round plug sits and turns when operated by hand or powered by an electric motor, air cylinder, or another power source. The plug has ports cut into it, which allow fluid or gas to pass through and block them off when closed.

Installation: Easy Setup Process

When it comes to installing an Actuator Brass Ball Valve, the process is simple. The setup requires minimal tools and basic plumbing knowledge, making it an excellent choice for users who are DIY-minded or those who don’t have access to professional installation assistance. This guide will help walk you through the steps necessary to successfully install your new brass ball valve.

The first step is ensuring you have all the necessary parts for assembly. In addition to the valve itself, you’ll likely need a pipe wrench, plumber’s tape, and some Teflon sealant paste. Once everything is gathered, place the ball valve at the desired location on your piping system. Make sure that it’s perpendicular so there won’t be any issues with water flow when used.

Maintenance: Regular Care Tips

Regular actuator brass ball valve maintenance is essential to ensure it lasts as long as possible and operates correctly. Maintaining the actuation valve helps guarantee a safe, secure system that performs optimally and avoids costly repairs or replacements. Here are some top tips for regular care of your actuator brass ball valve:

First, inspect your valve regularly to check for signs of wear and tear. Make sure any screws or bolts are securely fastened, and look for signs of corrosion. Additionally, clean the valves at least once a year with a mild detergent solution to prevent any build-up of debris that could interfere with its functioning. If you notice any damage, repair it immediately; this can often help minimize further problems.

Summary of Benefits

The actuator brass ball valve is invaluable for various purposes and industries. This type of valve offers numerous benefits, making it one of the most popular choices. This valve’s intuitive design allows for easy installation and maintenance while providing reliable control over the fluid flow. Its durability is unmatched compared to other materials, making it ideal for outdoor and indoor applications.

The actuator brass ball valve has been proven to be an exceptional choice for regulating liquids or air. Its simple operation provides effective control with minimal effort. Additionally, its corrosion-resistant qualities ensure long-term performance even under extreme conditions where other valves might fail. This makes the brass ball valve suitable for various uses, including plumbing, process control, and HVAC systems. Please contact us