Description

Water Temperature Control Valve /Thermostatic Mixing Valve

JX-0312

- 3 Way body; DN15-DN25 ( 1/2″ – 1 “)

- Driving model; Electric/Manual with position indicate;

- Descriptions Brass Thermostatic Mixing Valve

Material Brass H58-3 or CW617N

Processing Forging, CNC Machining

Surface Treatment Nickel Plated

Working Medium Hot/Coldwater

Cold Water Inlet Temperature 4°C-29 °C

Hot Water Inlet Temprature 40 °C -90 °C

Mixed Outlet Water Temperature 30°C -55 °C

Working Pressure 0.03-1Mpa

Control Precision ±2 °C

Flow Rate(1 kg pressure) 26.67 L/min

| Position | Min | 1 | 2 | 3 | 4 | 5 | 6 | 7 | Max |

| Temperature /℃ | – | 30 | 34 | 39 | 43 | 47 | 51 | 55 | – |

Rapid failsafe on either hot or cold supply failure

>> Imported sensor element delivers stable mixed water temperature

>> Extended mix temperature range: 30℃-55℃

>> Water pressure test with 100% no leakage

>> High-precision machining, professionally engineered, designed, and produced to give excellent performance.

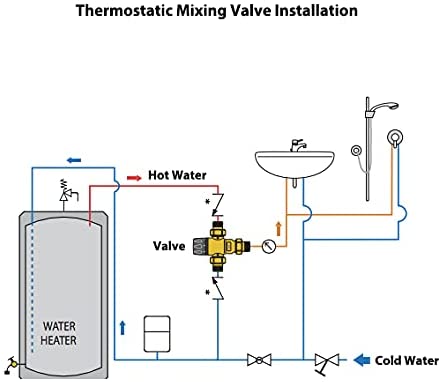

Thermostatic valve works

Thermostatic valve works

Benefits: Safety and Efficiency

The Water Thermostatic Mix Valve is changing how we think about safety and efficiency in our homes. This revolutionary valve helps you to easily maintain a safe and efficient water temperature at all times. The valve controls both hot and cold water temperatures to prevent scalding. It also ensures that hot water never exceeds your desired temperature, making it ideal for those looking for peace of mind when using it in their home.

The valve is easy to install and can be used with any type of faucet or shower system, making it an ideal choice for those wanting maximum safety and efficiency from their fixtures without having to make significant upgrades or replacements. The Water Thermostatic Mix Valve guarantees the safest possible water temperatures. It offers superior energy savings over traditional valves, helping you save money on your utility bills while ensuring the optimal performance of your fixtures.

Types of Valves

Valves are a crucial component of many systems, including the water thermostatic mix valve. Valves help ensure that liquids and gases are controlled in various environments, from heating and cooling systems to plumbing or other industrial applications. Several types of valves are available, each designed for specific purposes.

The two main categories of valves include non-return valves and control valves. Non-return valves allow liquid or gas flow in one direction only, while control valves regulate the pressure within a system by controlling the flow rate. The water thermostatic mix valve is an example of a control valve that helps maintain water temperature by allowing hot and cold water to be mixed as needed. Other types of control valves include check valves, safety relief valves, solenoid valves, and pilot-operated diaphragm actuators.

Benefits of a Water Thermostatic Mix Valve

A water thermostatic mix valve provides many benefits when incorporated into a building’s plumbing system. This type of valve helps to balance the hot and cold water supply, providing a steady stream of warm water at all times. This device is advantageous to the building’s occupants and businesses that rely on cleanly washed dishes and sanitized surfaces throughout their facility. The following describes how such devices can benefit both residential and commercial settings.

Water thermostatic mix valves can regulate temperatures even during periods of high demand. When hot and cold water is delivered simultaneously, the valves blend them accurately to provide warm water at a consistent temperature – preventing spikes in temperature that can cause scalding or burns for anyone using the tap or showerheads connected to it.

Typical Applications of a Water Thermostatic Mix Valve

A Water Thermostatic Mix Valve is a vital component of the plumbing in many homes and businesses. It helps to ensure that water is heated and cooled to the correct temperature for safety reasons and provides multiple other applications. The valve combines hot and cold water sources into one temperature-controlled output, making it an ideal solution for many applications requiring precise temperature control.

Typical applications of this type of valve include shower systems, dishwashers, laundry machines, and other appliances that require a specific temperature setting. It also serves as an essential safety measure in preventing scalding injuries by instantly shutting off the hot water supply if there is a sudden change in pressure or flow rate. Furthermore, it can help reduce energy costs by automatically adjusting temperatures when necessary while keeping them consistent over time.

Installation Tips for a Water Thermostatic Mix Valve

Installing a water thermostatic mix valve can be an intimidating task for those who are not familiar with plumbing. However, following a few essential tips, anyone can easily install their own water thermostatic mix valve. The main thing to consider is that the valve needs to be installed on the cold side of the system to ensure proper operation. Additionally, selecting a location that is as close as possible to where the hot and cold water will merge to create an even mixture of temperatures is essential. Other factors, such as ensuring proper insulation placement and testing for leaks, should also be considered before beginning installation. By keeping these crucial steps in mind, anyone can successfully install their own water thermostatic mix valve!

Maintenance of a Water Thermostatic Mix Valve

Water Thermostatic Mix Valves are essential components of a plumbing system, as they provide precisely regulated hot water for tasks such as showering, dishwashing, and laundry. As with any other mechanical device, proper maintenance of a water thermostatic mix valve is essential to ensure efficient operation and reduce the chances of costly repairs down the road.

The most important part of maintenance for any water thermostatic mix valve is regular inspection and cleaning. Before inspecting or maintaining a water thermostatic mix valve, it is essential to turn off all power sources associated with the valve. This will ensure that no electrical shock occurs during the process. Visual inspections should be done monthly to check for signs of corrosion or damage to the valve parts.

Conclusion: Safe and Efficient Temperature Control

Temperature control is a significant concern for many industries. One way to ensure that temperature is safely and efficiently managed is by using a water thermostatic mix valve. This device combines two water sources at different temperatures to create an output of preset temperature, providing precise control over the flow and temperature of the water.

Using a water thermostatic mix valve helps ensure safety in many industries. For example, it can be used in food production facilities where maintaining consistent temperatures is critical for food safety and quality control while also helping to reduce waste materials due to incorrect temperatures. The mixing valve can also be used in hospitals, other healthcare settings, and industrial processes such as oil refining or chemical manufacturing.

Overall, using a water thermostatic mix valve provides an efficient way to maintain safe temperatures for various purposes across multiple industries.

More Guide Information

1. A Licensed Professional should carry out installations.

2. Install the following markings on the valve body. i.e., hot water inlet-marked H, cold water inlet-marked C.

3. After temperature setting, outlet temperature variation is within +/-2 C if inlet temperature or pressure fluctuates.

4. The external check valves at inlets prevent cross-flow of hot&cold water when inlet pressure is not the same.

5. If the ratio between two inlets is too large, one flow-limiting valve should be fixed at the side of higher pressure.

6. Before installation, provisions should be made to flush the piping of any debris or other foreign materials to ensure proper system operation.

A thermostatic mixing valve is a plumbing fixture mixes hot and cold water to provide the desired temperature. Installing one should be done by a licensed plumber, but if you’re feeling brave enough, this guide will help walk you through the process!

The first step is to shut off the water supply. This can be done by turning a knob on the wall near your sink. Once the water has been turned off, you can remove the old faucet. There are usually two screws at the base of the faucet that needs to be removed.

Once the faucet has been removed, it’s time to install the new one! The thermostatic mixing valve should go between the hot and cold water lines. It must be installed in the correct spot, or you could end up with scalding water coming out of your faucet!

Once it’s in place, reattach the screws removed earlier and turn on the water supply. Test out your new faucet by running hot and cold water through it. If everything looks good, you’re done! Congratulations, you’ve just installed a thermostatic mixing valve!

It’s essential that the thermostatic mixing valve is installed in the correct spot, or else you could end up with scalding water coming out of your faucet!

– – The first step is to shut off the water supply. This can be done by turning a knob on the wall near your sink. Once the water has been turned off, you can remove the old faucet. There are usually two screws at the base of the faucet that needs to be removed … – The thermostatic mixing valve should go in between hot and cold water lines. It must be installed in the correct spot, or you could end up with scalding water coming out of your faucet! – Once it’s in place, reattach the screws removed earlier and turn on the water supply. Test out your new faucet by running hot and cold water through it. If everything looks good, you’re done! Congratulations, you’ve just installed a thermostatic mixing valve!