Description

|

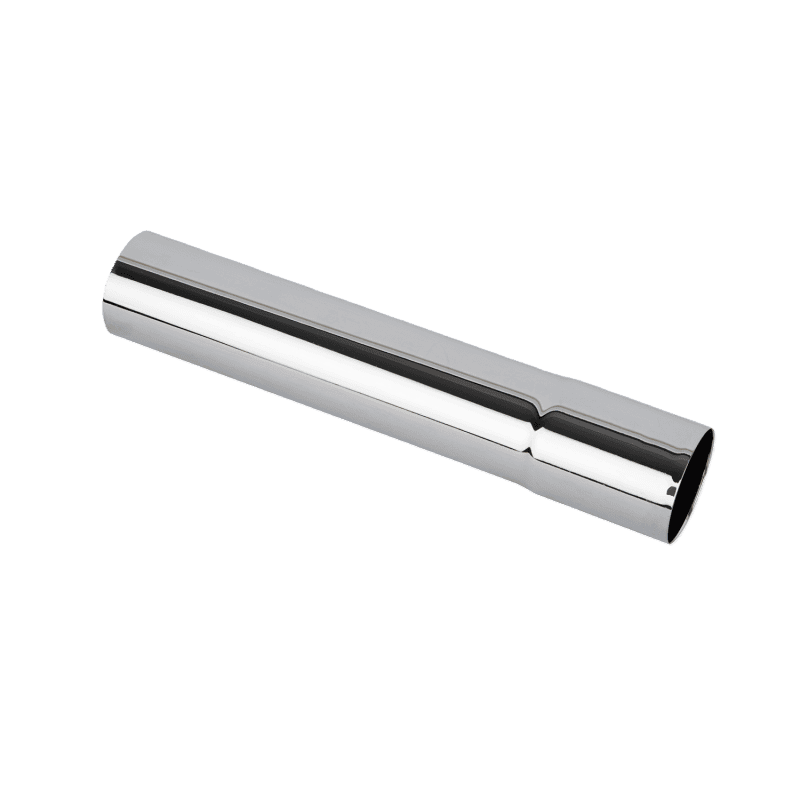

Brass Water Meter Coupling

Brass-Water-Meter-Coupling-Connector is the core accessory for water meter installation in plumbing systems, which is widely used in water supply and drainage pipes of residential buildings, commercial buildings, industrial plants, and other locations. Its core purpose is to realize the rapid and sealed docking of the water meter and the water inlet and outlet pipeline, which can effectively ensure the smooth transmission of water flow in the water supply and drainage system, and prevent water leakage through reliable sealing performance. It is a key connecting component to ensure normal measurement of the water meter and maintain stable operation of the pipeline system.

|

|

|

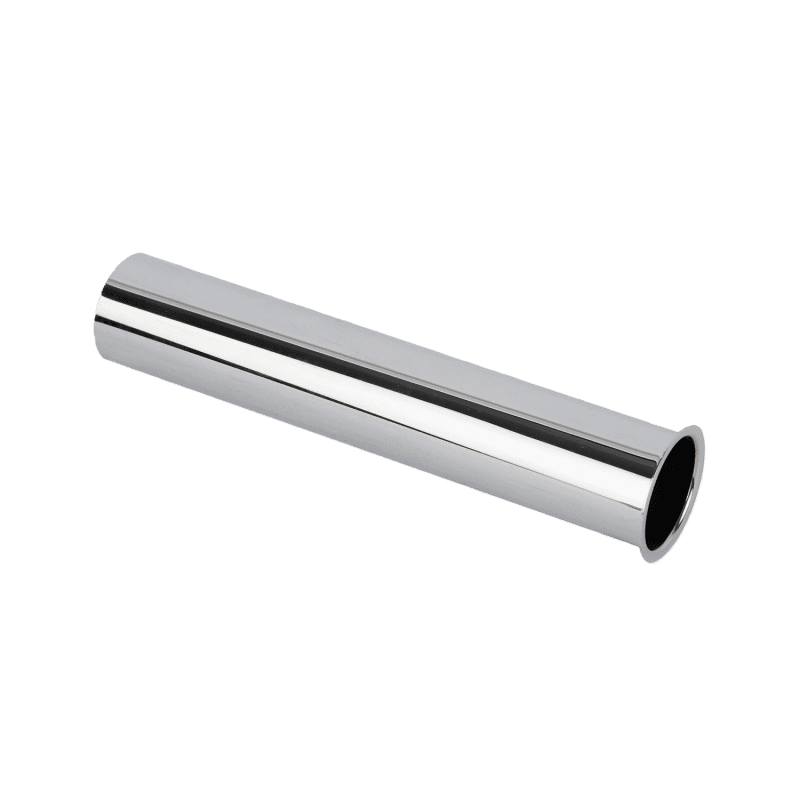

Brass Trap Connector Brass waste connectors are plumbing (plumbing) common accessories in the system, widely used in basins, sinks, bathtubs, washing machines and other sanitary ware or water equipment drainage scene use is to connect the sanitary ware drain and sewer pipe, to build a smooth drainage channel, can withstand sewage erosion for a long time, effectively prevent leakage, odor backflow and other problems in the drainage process; Adapts to various specifications of the drain and pipe, flexible connection (thread or buckle type), easy installation and disassembly, is to ensure that all kinds of water equipment drainage smooth, maintain the indoor environment dry key connection components

|

|

|

Brass Male Y-Strainer Brass male threaded Y filters with BSP threaded connections are critical filtration accessories in plumbing and fluid delivery systems, especially where media cleanliness is required, or downstream equipment needs to be protected. Y-type structure design with a high-precision filter can efficiently intercept rust, sand, impurities, and other particles in the fluid. Its core use is to protect valves, pumps, water meters, and other precision equipment from wear or blockage. BSP thread (British pipe thread) connection mode adaptability, easy installation, and disassembly.

|

|

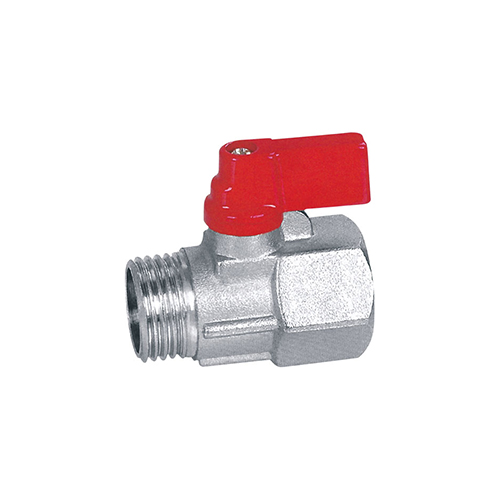

Nickel Plated Brass Mini Ball Valve

A nickel-plated brass miniature ball valve with Male and Female connections, it is the core of precision control in small fluid systems, especially for space-constrained or small-diameter pipe control requirements. Miniature design does not occupy too much installation space, external thread and internal thread double interface matching, can flexibly adapt to the same specification of small diameter pipeline or equipment interface, easy to install; through 1/4 rotation can quickly open or close the fluid, excellent sealing performance, can effectively prevent water, gas, neutral liquid and other media leakage, accurate control of fluid on and off, not only convenient for daily use and operation, but also convenient for maintenance of small equipment.

|

|

|

PTFE Brass Gas Ball Valve

The gas angle cock ball valve is a core accessory with steering and control functions in the gas transmission system, suitable for narrow installation spaces or complex pipeline layouts where the gas flow direction needs to be changed. Adapt to a variety of specifications of gas pipeline; Angle structure can achieve 90 degrees of gas pipeline steering, integrated plug valve precision control function, through the rotation of the handle can quickly open or cut off the gas supply, flexible operation and excellent sealing performance, not only convenient for daily use of gas switch control, but also convenient for gas equipment maintenance, is to ensure the safe and stable operation of the gas system key components.

|

|

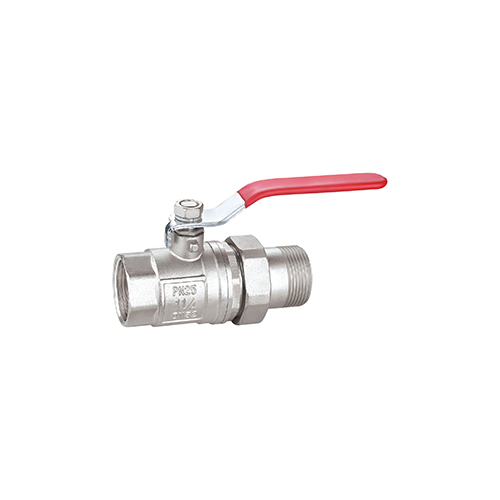

1/2″ Ball Valve with union threaded connection A ball valve with a loose joint thread connection is a common valve fitting in a fluid control system. The main body is usually made of brass, stainless steel, and other corrosion-resistant materials. The core feature is that both ends of the valve are equipped with a loose joint thread structure. It can be quickly installed, disassembled, and repaired by rotating the loose joint nut without cutting the pipeline, greatly improving the construction and maintenance efficiency. It not only ensures the smooth transmission of fluid in the pipeline system but also avoids damage to the overall pipeline during equipment maintenance and valve replacement. It is a key fluid control component that considers both practicality and convenience.

|