FAQs of Transition Curve Pipe Fitting

1. What is the difference between Transition Curve Pipe Fitting and Transition Curve Fitting?

Same diameter transition joint, with both ends of the interface having a nominal diameter consistent with each other. Reducing the transition joint, the nominal diameters of the two ends of the interface are different. The same diameter joint is suitable for turning and connecting pipes of the same specification; the reducing joint is suitable for connecting and regulating the flow of pipes of different specifications. The type selection shall be comprehensively judged in combination with the core requirements of B-end, such as pipe diameter planning, fluid characteristics, and installation environment of the pipeline system.

2. Can Transition Curve Pipe Fitting be used on soft substrates?

Transition Curve Pipe Fitting can be used for soft substrates. Soft base materials include PVC and aluminum alloy pipes, among others. But it needs to be used with a customized structure or special accessories. When soft substrates are matched with transition joints, two points should be paid attention to: one is to select seals corresponding to hardness according to the hardness of the substrate to avoid extrusion damage to the substrate by hard seals; the other is to control the tightening force during installation, and the thread connection torque should not be too large to prevent deformation and damage of soft substrates due to excessive stress.

3. Can Transition Curve Pipe Fitting be installed or removed under pressure?

Regular Transition Curve Pipe Fitting is not recommended to be installed or removed directly under pressure; only the specially customized “Pressure Operated Transition Fitting” can be performed when certain conditions are met. Conventional operation under pressure may result in sealing failure or damage to the pipe. If shutdown and pressure relief are not possible in industrial scenarios, a specially designed transition joint with pressure operation is required.

4. Can you provide Transition Curve Pipe Fitting installation instructions and technical support?

Plumberstar, as a professional valve and pipe fitting foreign trade factory, provides comprehensive and standardized Transition Curve Pipe Fitting installation guidance and technical support services for global B-end customers.

Provide a paper installation manual with supporting technical data documents. Installation instructional videos are also available.

Before installation, the customer provides the pipeline system parameters, and can consult us about the working condition adaptation; during the installation process, support immediate consultation and installation quality verification guidance; after installation, clarify the maintenance cycle under different working conditions, and guide the customer to carry out daily maintenance operations. Perform troubleshooting and propose solutions.

5. How fluid compatible is Transition Curve Pipe Fitting?

The fluid compatibility core of Transition Curve Pipe Fitting produced by Plumberstar depends on the material selection and seal configuration. There are apparent differences in the adaptability of various material joints to different fluids, such as water, gas, oil, and chemical media. At the same time, it needs to be comprehensively judged in combination with working conditions. The 304 stainless steel transition joints are the most widely used, general-purpose materials. Apply to clean water, softened water, and other similar liquids. Seawater and chlorine-containing wastewater can be short-term compatible, but for long-term use or when the chlorine concentration is too high, it is recommended to use 316L stainless steel. Brass transition joint, cost-effective choice, more suitable for plumbing, civil scenes, such as tap water, hot water, non-corrosive gases, etc. PVC plastic transition joint is light corrosion resistant, suitable for water supply and drainage, and chemical environments.

The B-end customer needs to provide detailed working condition parameters when selecting models. The factory can meet the fluid transmission requirements of most industrial and civil scenarios through a standardized material system and customized configuration. At the same time, it provides a material inspection report and compatibility verification service to ensure long-term stable operation of the pipeline system.

6. Transition Curve Pipe Fitting When conveying corrosive media, what should be paid attention to besides the material?

When transporting a corrosive medium, in addition to the material, it is also necessary to control the dimensions of sealing parts and structural design to avoid problems such as medium leakage and joint damage, ensuring the stable operation of the transportation system.

Seals are the key to preventing leakage of corrosive media, and their materials must match the media. When conveying strong corrosive media, such as strong acids, alkalis, or organic solvents, FKM or PTFE seals are preferred. If the medium is corrosive oil containing chlorine, nitrile rubber seals should be avoided, as they are easily corroded and prone to aging. At the same time, attention should be paid to the seal’s structure. Under high-pressure conditions, the seal should be equipped with a retaining ring to prevent it from being extruded and deformed by the medium to avoid sealing failure.

An unreasonable structure will lead to medium residue or stress concentration and accelerate corrosion. On the one hand, the joint with lining can be selected, which can isolate the contact between the medium and the joint body to reduce corrosion; on the other hand, the parameters of the joint surface shall be controlled, and the labyrinth seal structure shall be adopted for the joint surface, the gap shall be ≤0.1mm, and the surface roughness Ra shall be ≤6.3μm, to avoid local corrosion caused by the residual medium in the gap. In addition, the joint cavity should have sufficient compressive strength, recommended to withstand 1.5 times the design pressure, to prevent corrosion caused by thinning of the wall thickness, and to be able to withstand the medium pressure without rupturing.

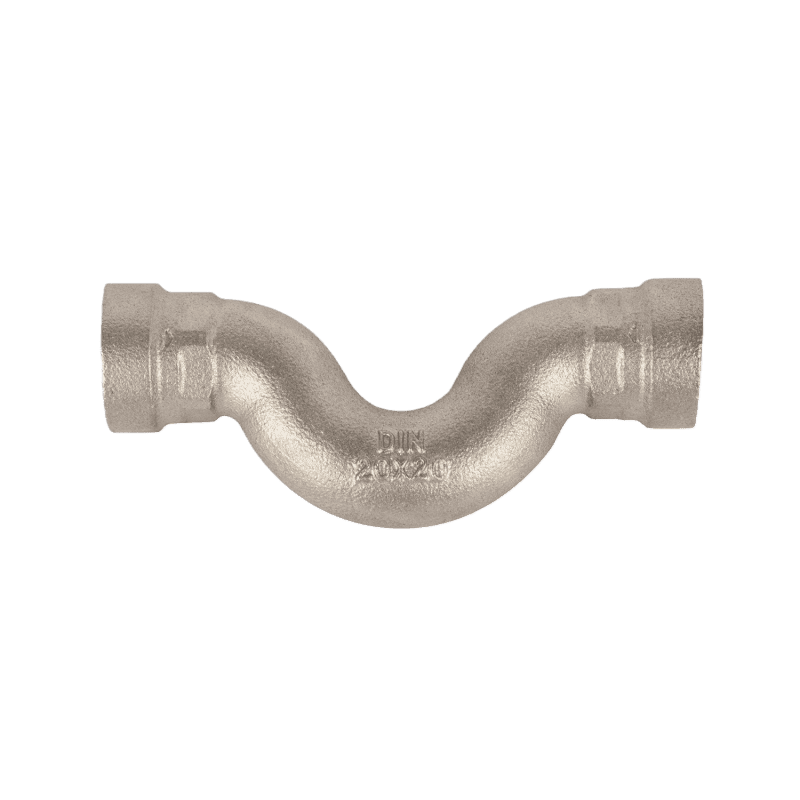

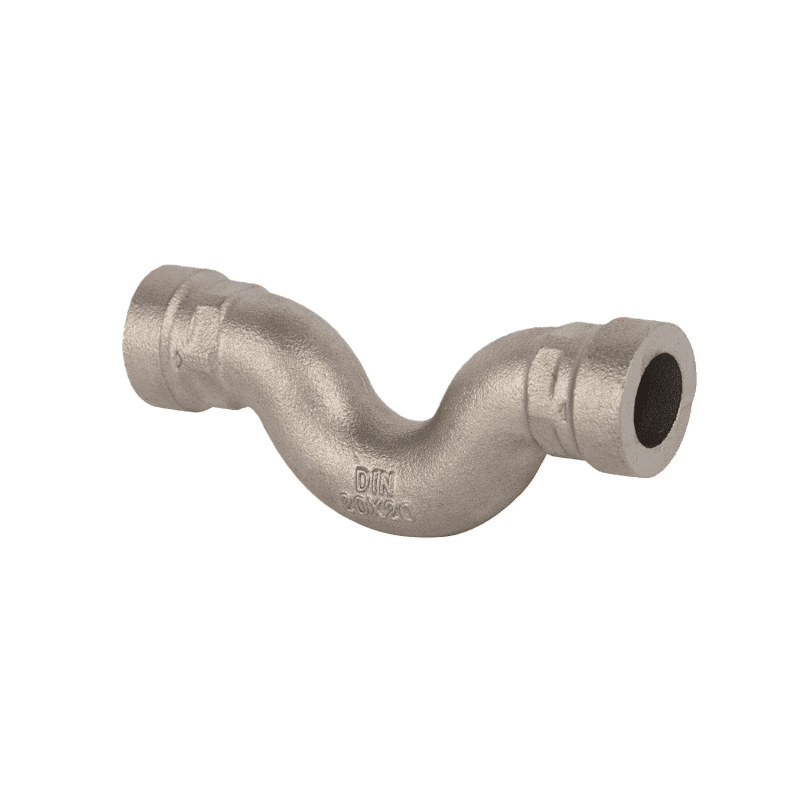

7. Transition Curve Pipe Fitting How to select the steering angle of the same diameter joint?

The transition curve pipe fitting, which involves selecting the same-diameter joint steering angle, must be combined with the installation space size, fluid characteristics, operating pressure level, and later maintenance requirements to make a comprehensive judgment.

The installation space is compact, and the short radius 90° joint is preferred. The space is extremely narrow, and the 45° joint combination steering can be adopted.

Open space, optional long radius 45°/90° joint;

Common clean fluid can be used for a 90° joint to achieve a right-angle turn or 45° to create a smooth connection.

An 180° folding joint shall be selected for turn-back transmission, and a 0°-90° adjustable angle joint shall be selected for flexible angle adjustment to ensure steering adaptation in the scene without affecting fluid transmission efficiency or joint service life.