FAQs of Multibloc Pressure Control Valve

1. Can you provide an MTC report for the multibloc pressure control valve?

Plumberstar provides complete, standardized MTC for multibloc pressure control valves.

The report clearly marks the product model, batch number, and production date. It also details the materials of all core components—valve body, valve core, seals, valve stem, and more. This includes brass grades, material types, chemical composition analysis data, and key physical performance indicators such as hardness and tensile strength. All material information is fully traceable and verifiable.

Our MTC reports are issued in accordance with international standards such as ISO and ASTM and follow relevant testing specifications. They’re certified by Plumberstar’s quality inspection department, together with third-party authoritative testing institutions. We provide both paper and PDF electronic versions of the goods, by batch. This meets all compliance requirements for engineering project acceptance, quality review, and long-term archiving.

2. Can the multibloc pressure control valve’s set pressure be customized?

Of course, pressure can be customized.

When you send us your customization needs, Plumberstar’s technical team will first discuss the actual working conditions of all the valves with you. This includes the application scenario, target set pressure range, and flow requirements, making sure we fully understand your end-system needs. Our engineers will then calculate and select a spring with the right stiffness, along with a matching diaphragm material and thickness, to achieve the set pressure precisely.

Every customized valve is calibrated individually on a high-precision pressure test bench. Once it reaches the target pressure, we lock the adjustment mechanism. This stops parameter deviations during transportation and installation, making sure the pressure value you receive is stable and reliable.

We also provide a complete factory test report for each batch of customized products. The report clearly states the set pressure and actual test results, meeting all needs for project acceptance and quality traceability.

3. Can you provide technical drawings for the multibloc pressure control valve?

Of course. Plumberstar provides complete, standardized technical drawing sets for multibloc pressure control valves.

They’re ready to use directly for model selection, engineering coordination, and project delivery. The drawings are available in CAD vector format, high-definition PDF, and JPG/PNG formats, making them easy to use across different scenarios.

- Core drawing content includes assembly drawings, detailed part drawings, sectional views, and installation dimension drawings, plus clear pipeline connection diagrams. They fully meet the reference needs for design, installation, technical review, and other work links.

- All drawings clearly mark key technical indicators: key dimensions, tolerance grades, diameter specs, mounting holes, connecting threads, and pressure parameters. We also specify each component’s material, assembly requirements, and sealing structure details in full. This ensures the drawings match actual product parameters exactly and can be put into use directly.

- If you need exclusive technical drawings for specific specs or non-standard modified products, just provide the detailed parameters or requirements. Our technical team has 10 years of experience and can finish custom drawings in 1-3 working days. We make sure the drawings are accurate, professional, and a perfect match for the physical products.

4. Is the multibloc pressure control valve suitable for EU markets?

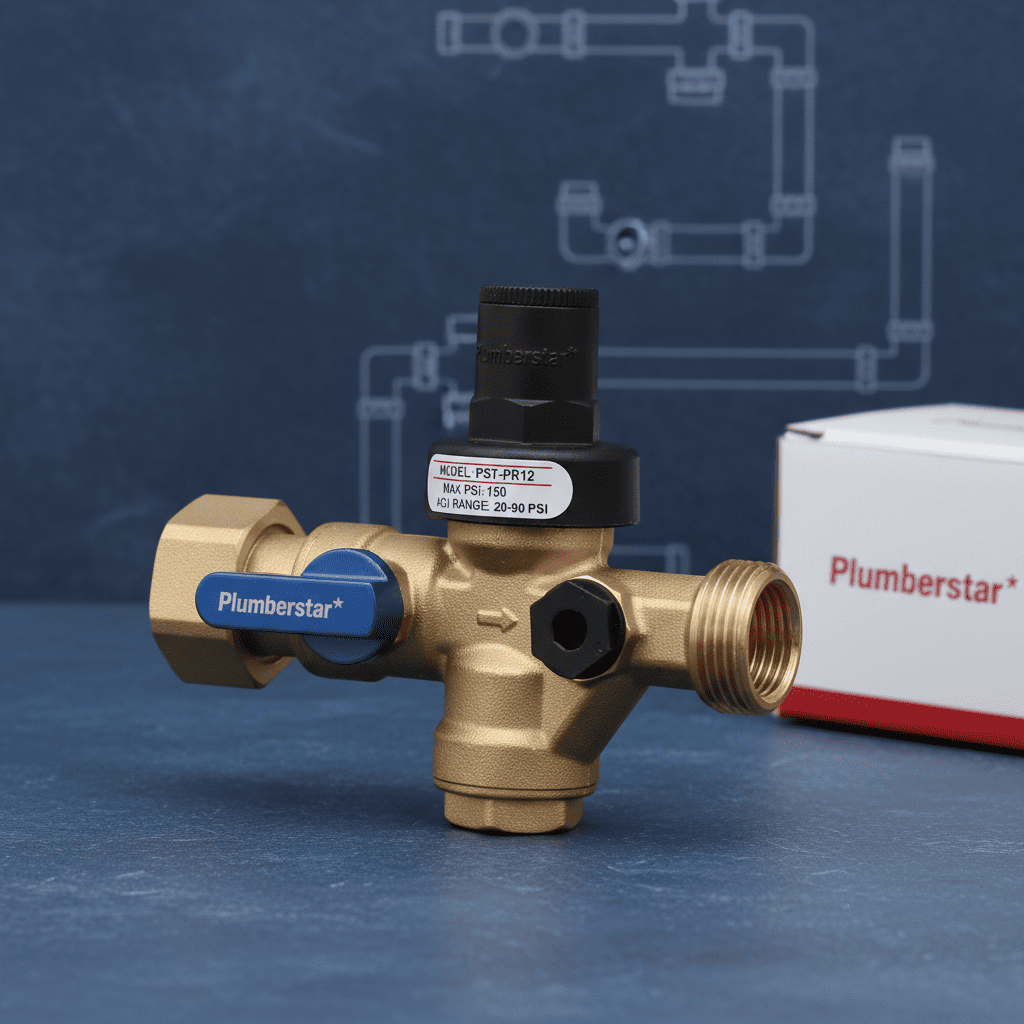

Our valve bodies and core components are made of eco-friendly materials that comply with EU RoHS and REACH directives. No heavy metals or harmful plasticizers are included. The whole manufacturing and surface treatment processes also follow EU environmental requirements. This eliminates customs clearance risks or market sales restrictions caused by non-compliant materials right from the start.

- For waterway and water supply system use, all valves use low-lead or lead-free brass materials, such as CW510L or DZR brass. They meet mainstream EU drinking water hygiene standards such as DVGW and French ACS. This ensures water quality safety and pure water output during long-term use, making them suitable for drinking water and domestic hot water systems.

- On interface adaptation, our products all use the European universal BSP thread standard. They can be directly compatible with local common pipeline and fitting systems, cutting down on-site installation adjustments and boosting construction and replacement efficiency.

- Considering the actual working conditions of heating and water supply systems in the EU, we’ve made targeted design and verification for the products’ pressure resistance, temperature resistance range, and flow stability. They can adapt to water pressure and temperature fluctuations across different EU countries and regions, ensuring stable, reliable long-term operation. This fully meets local users’ requirements for system safety and durability.

5. Does the multibloc pressure control valve support OEM customization?

Plumberstar is a professional custom valve manufacturer. We’ve long provided mature, stable OEM customization services for overseas brand owners, engineering projects, and system integrators.

We can laser engrave or silk-screen print your exclusive logo, brand name, product model, and key parameters on the valve body. We also customize the valve body’s surface treatment process based on your brand positioning, and adjust the handle style and color scheme. This boosts the overall brand recognition and appearance consistency, while keeping the product practical.

For specific working conditions, we support customizing and fine-tuning the valve’s core functional parameters. This includes pressure regulation range, flow coefficient, opening or pressure relief threshold, and more. We can also add extra functions like filter screens, anti-backflow, and water shutoff as needed.

What’s more, our technical team is involved in the entire OEM customization process. We offer one-on-one technical support from demand communication and program confirmation through sample production to mass production. This ensures the final product meets your brand positioning and actual usage needs in terms of performance, appearance, and application, helping you expand your target market more efficiently.

6. Does the multibloc pressure control valve support mixed-model shipments?

You just need to send us your product list. No matter if it’s multibloc valve combinations of different specs, or complex mixed orders with valves, pipe fittings, manifolds, floor drains, and other categories, Plumberstar can take them all and execute efficiently.

During production, our project team coordinates all production lines in a unified manner, ensuring all products are produced within the agreed time. Every product undergoes a 100% pressure test, ensuring consistent performance and quality across the board. pack and ship everything together, reducing the cost and hassle of receiving multiple shipments and having to repeat related work.

Each product model in a mixed order will come with the corresponding certificate of conformity, user manual, and other documents. We also provide a single delivery note and packing list for the entire order, with all models and quantities clearly matched. This makes it easy for you to check and verify when receiving the goods.

7. What’s the lead time for the multibloc pressure control valve?

Plumberstar’s delivery times for multibloc pressure control valves fall into two types: regular stock orders and customized/bulk orders.

- Regular bulk ordersWe arrange production based on the production plan. Production, full inspection, and shipment are all finished within 7-15 working days. The exact time can be adjusted slightly based on your order quantity.

- OEM customized ordersBasic customization—like logo engraving and packaging customization—has the same delivery time as regular bulk orders, 7-15 working days. For in-depth customization that involves parameter adjustments and structural changes, delivery takes 20-30 working days. This time includes sample making, confirmation, and mass production.

- Rush ordersIf you have urgent procurement needs, you can apply for rush production scheduling. Stock items can be shipped the same day. For bulk or customized items, delivery time can be cut by 30%-50% based on the actual situation. This needs to be negotiated and confirmed with our sales manager first.

Once your order is confirmed, we’ll give you clear delivery time notes right away. You can track production progress in real time throughout the process. After shipment, we’ll send you the logistics tracking number and provide full tracking, ensuring the goods arrive on time.