Description

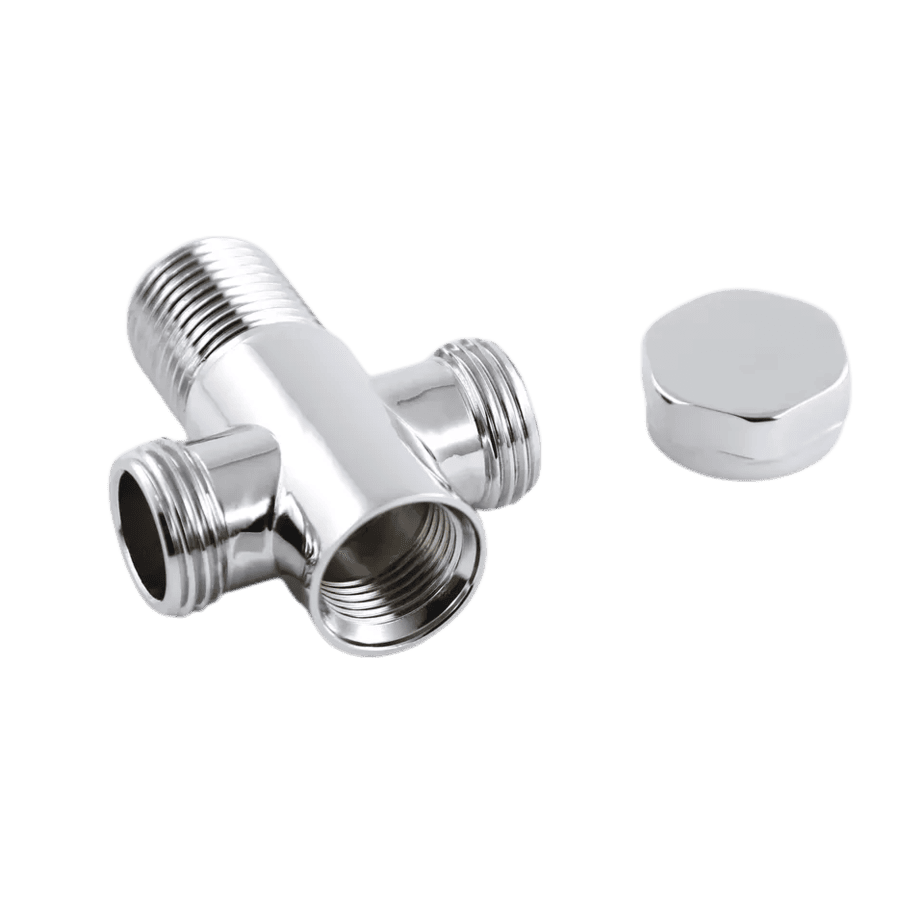

Toilet Water stop angle valve

JX-0201

Angle Valve

Size 1/2″ X1/2″,1/2″ X1/2″

Brass Body With Chrome plated

Max work temperature: -10-120℃

The max working pressure is 12 bar

Brass cartridge

3 million times open-off working is guaranteed

The angle stop valve regulates the water flow to the toilet cistern and is an essential component of the toilet plumbing system. The valve body and the internal cartridge or stem assembly comprise it. It is commonly situated in close range to the wall behind the toilet. As time passes, these internal components may deteriorate, resulting in leakage or challenges in deactivating the water supply.

This particular variety of shut-off valves is resilient and can operate efficiently for many years. Stop valves are fabricated using chrome-plated or brass finish.

Why Are Toilet Angle Stop Valves So Important?

As previously stated, an angle stop valve regulates water flow to a specific appliance while leaving the entire building unaffected. While professional plumbers are working to fix the breach, an angle stop valve serves the purpose of averting water damage. When repairing a faulty faucet, an angle stop valve can prevent you from imposing thousands in water damage or having the water to your entire house turned off for hours.

Additionally, angle stops are quite practical for home renovations. For instance, using an angle stop, it is possible to replace a solitary water-using appliance in a dwelling without stopping the water supply to the entire house or structure.

Where in Your Home Do You Find Angle Stop Valves?

These are five possible locations for angle valves in your house:

- Under your toilet (cold water angle valve)

- Your washbasin can have hot and cold water angle valves

- Your under-sink sump pumps have hot and cold water angle valves

- Two cold water valves to your water heater

- If your home has a water purifier, a cold water angle valve will be installed

Angle Stop Valves: Why Material Matters?

At this time, angle stop valves vary in quality. These tiny devices are available in various materials, including brass, copper, and plastic. Thus, what is the distinction, and why is it significant?

Brass valve angle stop valves are a durable variety as robust as steel. Copper is also quite satisfactory, particularly for those concerned with corrosion resistance. Plastic material? Despite recent additions, it is safe to state that they may not be the most helpful in the long run.

Brass Angle Stop Valves

Due to its resilience and corrosion resistance, brass is the gold standard for angle stop valves. However, wear and tear can appear on even these stalwarts. Search for:

A color alteration could serve as an indicator of oxidation or corrosion.

Leaks: Moisture or drips around the valve are cause for concern.

Durability: If the valve is difficult to move, it may be time to replace it.

Plastic Angle Stop Valves

Plastic valves generally exhibit reduced durability and are more prone to deterioration. Consider the following:

Cracks: Plastic can become brittle, which can result in the appearance of fractures.

Warping: The valve may undergo deformation due to exposure to elevated temperatures.

Discoloration: In contrast to metal valves, plastic valves are susceptible to discoloration due to chemical reactions involving water.

Stainless steel Angle Stop Valves

Stainless steel, recognized for its corrosion resistance, is a more reliable material. However, it ultimately leads to deterioration.

Greenish Deposits: The appearance of verdant deposits, such as a patina or coating, on the surface may indicate possible corrosion.

Loose Fittings: The integrity of the valve may be compromised if it appears to be swaying or is not fastened.

Decreased Water Flow: An apparent reduction in water pressure shows internal deterioration.

For timely maintenance or replacement, it is critical to recognize the indications of deterioration on any material of angle stop valves. Unexpected plumbing emergencies and expensive repairs may be averted with this proactive technique.

How Often Should Your Angle Stop Valve Be Changed?

It is recommended that angle stops be replaced every 8-10 years if not in use. The expense of replacing an angle stop in one’s house is quite nominal. Many plumbing companies offer discounts when all angle stop valves are replaced at once.

Performing an angle stop “activity” is essential at least once per month, even if the stop is not utilized. This ensures that the angle stop maintains its lifespan by preventing it from seizing.

Several turns of the handle will cycle it on and off. When the knob remains immobile, refrain from exerting force to rotate it. This could lead to the failure of the valves. Consult a professional if intervention is required.

Angle Stop Valve Applications

Angle stop valves are used in plumbing systems catering to residential, commercial, and industrial needs. Through angle stop valves, water fixtures are linked to the water supply pipelines trailing the plumbing network.

Angled stop valves are required to install the fixtures perpendicularly in the water supply pipelines. The primary function of angle stop valves is to create a separation between water fixtures and the water supply. It enables maintenance or replacement to be performed on the fixtures.

Angle stop valves are also utilized in industrial systems to isolate a specific system section for maintenance purposes. They are also implemented to regulate pressure. The right-angle configuration prevents pressure surges in the system by forming a pressure decrease across the valve. Angle stop valves may be implemented when a 90° change in flow direction is required.

Could you please feel free to contact us with more information about angle valve requirements?