FAQs of Mixing Tank Manifold

1. What are the advantages of the Mixing Tank Manifold?

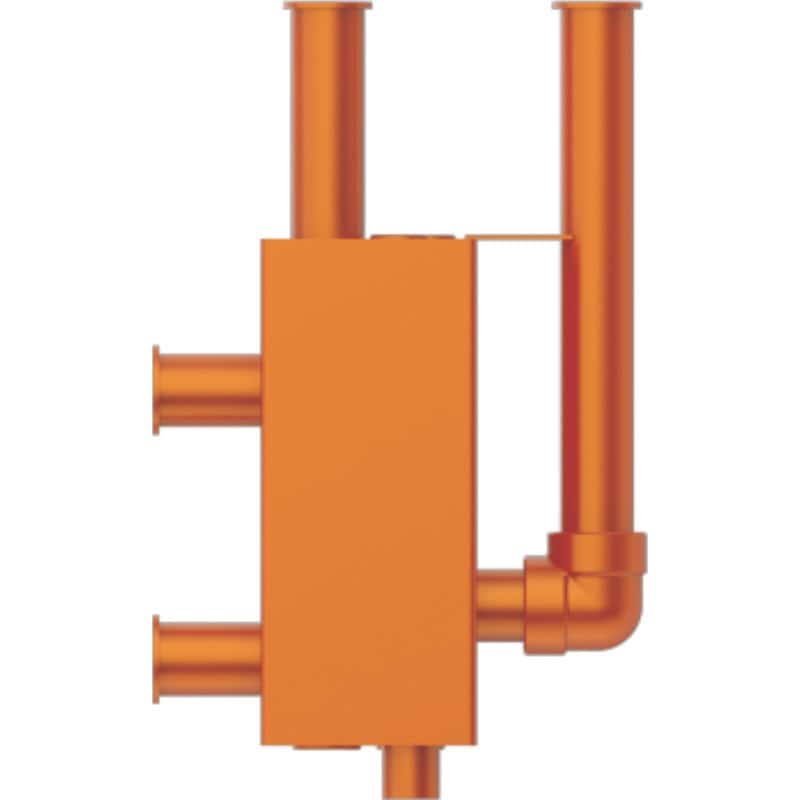

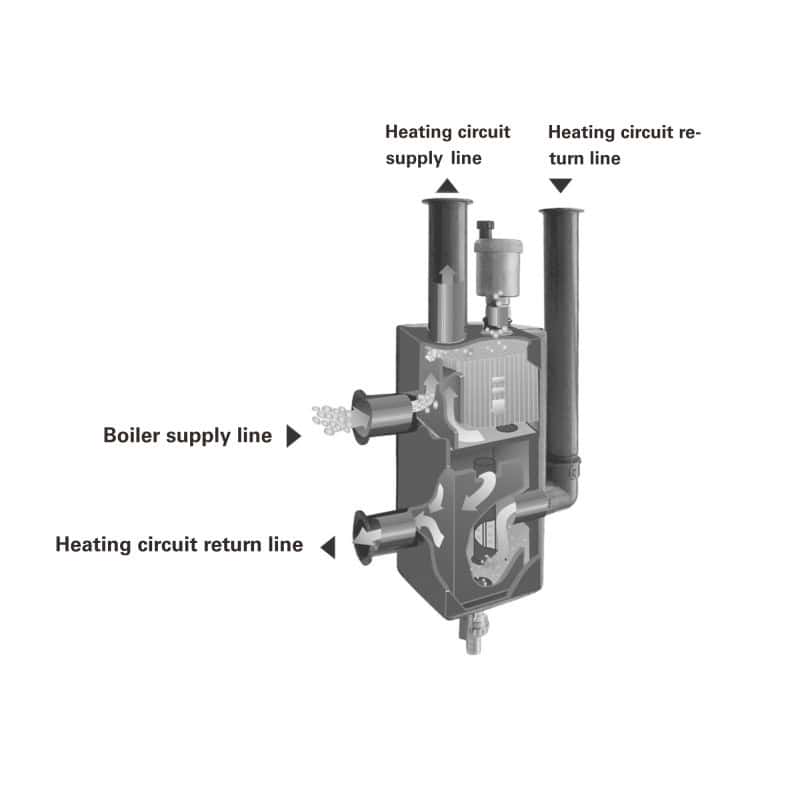

The Mixing Tank Manifold is designed to combine the mixing tank and the manifold into one unit. This helps simplify and make the heating system layout easier to manage. Because fewer pipes, valves, and connectors are needed, installation time is shorter, and the risk of water leakage is lower.

In one body, hot water from the heat source is mixed with cooler return water. This helps the system reach a stable temperature more quickly and keeps water flow balanced between different heating lines. Each floor heating loop or radiator can receive more even heat.

The integrated structure also makes it easier to install air vents, drain valves, and flow meters in a single location. System adjustment, daily checks, and maintenance become more convenient. This design is especially suitable for villas and small commercial buildings where space is limited and stable heating is important.

2. Can the Mixing Tank Manifold reduce the operating noise?

The Mixing Tank Manifold helps reduce noise when the heating system is running. The integrated mixing tank creates a stable water pressure area inside the system. This helps separate the primary heat source pump from the circulation pump at the heating end, reducing pressure changes and vibration in the pipes that often cause noise.

At the same time, the manifold distributes water evenly to each heating loop, maintaining a smooth and steady flow. This reduces the noise caused by fast water flow, sharp pipe turns, or sudden changes in pipe size. Some models are also equipped with a quiet air vent that releases trapped air in a timely manner, helping to prevent gurgling or knocking sounds. Overall, it makes the heating system run more quietly and comfortably, especially in homes and villas where low noise matters.

3. Does the packing of the Mixing Tank Manifold conform to the standard for sea transportation?

The Mixing Tank Manifold is packed to suit long-distance transport and sea shipping. Main metal parts, such as the tank and manifold, are first covered with anti-rust film to block moisture. Then EPE foam or high-density padding is used to wrap corners, joints, and other parts that may be easily damaged.

After that, the product is placed in a thick five-layer carton. Bubble wrap and moisture-absorbing desiccant are placed inside the carton to reduce movement and prevent moisture. For large unit or bulk orders, use custom wooden pallets wrapped in waterproof stretch film. This protects the product from bumps, pressure, and humidity during transportation, ensuring it does not rust, deform, or sustain damage.

4. Is the Mixing Tank Manifold export documentation prepared by Plumberstar?

We are responsible for preparing export documents for the heating system Mixing Tank Manifold. Based on the customer’s order and the customs rules of the destination country, we provide the necessary export papers. These usually include the commercial invoice, packing list, bill of lading, product certificate, material inspection report, and certificate of origin.

We can provide additional certificates and copies, such as CE and PED, etc. We prepare the documents required for export for customers free of charge. We ensure that the papers meet customs requirements and can be cleared without any issues.

5. Does Plumberstar have aftermarket Mixing Tank Manifold service outlets in foreign countries?

As of December 2025, Plumberstar does not have its own service offices in other countries for Mixing Tank Manifolds. Instead, we collaborate with local partners to support our customers.

In places like Europe and North America, local partners help with installation, repair, and parts replacement. If customers need help, our main team can also provide online support within 24–48 hours. We provide simple manuals and video guides to explain how things work. We also maintain a stock of common spare parts in nearby warehouses, allowing parts to be sent more quickly and problems to be resolved more easily.

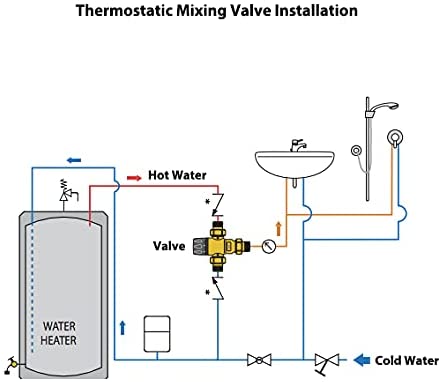

6. Can the Mixing Tank Manifold be adapted to different heating terminals?

The Mixing Tank Manifold can be used with various heating types, including floor heating and radiators. Floor heating requires warm water with a higher flow, typically around 40–50℃, while radiators require hotter water with a lower flow, usually around 60–80℃. This device combines hot water and cold water. Then it sends the right amount of warm water into the heating pipes. Each pipe can be adjusted on its own. This helps prevent floor heating from becoming too hot or too cold. With separate valves and simple temperature controls, the system can run safely and smoothly in many heating situations.

7. What are the wearing parts of the Mixing Tank Manifold?

In a heating system mixing tank, some parts will wear out over time. These usually include valve seals, O-rings, exhaust valve parts, and filter screens. They come into contact with water frequently and are frequently opened and closed, which can cause them to become old, worn, or clogged. As a B2B supplier, Plumberstar maintains a long-term availability of these spare parts. Standard parts are often shipped with the product, and additional parts can be supplied later from our local warehouses or main stock. This helps customers handle repairs and maintenance more easily.

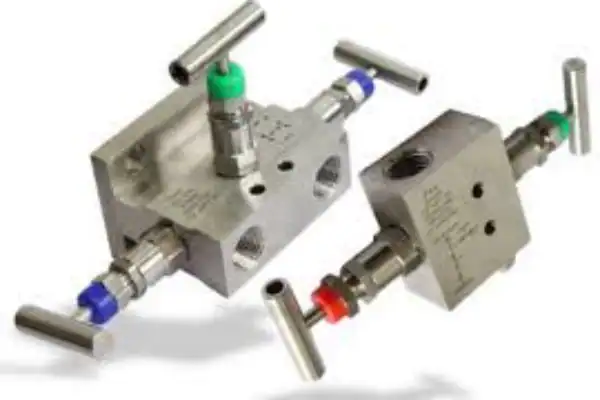

8. When should stainless steel mixing tank manifolds be used instead of brass?

The stainless steel stirred tank pipeline should replace the yellow copper pipe, mainly focusing on the strong corrosive medium, high hygiene standards, high temperature, and high-pressure conditions, and outstanding long-term stability requirements:

When the medium treated by the stirring tank is an acid-base solution, salt spray environment, or chemical corrosive raw materials, the corrosion resistance of stainless steel is far superior to that of brass, which can avoid pipeline corrosion leakage and contaminated materials.

In the food, medicine, daily chemical, and other industries with strict requirements for hygiene grade, stainless steel is easy to clean, poses no risk of heavy metal precipitation, and complies with GMP and other relevant certification standards. In contrast, copper ions in brass may penetrate materials, potentially affecting product safety.

When the working conditions involve high temperatures (usually more severe than 200℃) or high pressures, the mechanical strength and heat resistance of stainless steel are enhanced, and deformation and aging problems are less likely to occur.

In addition, for mixing systems that require long-term continuous operation, stainless steel pipes have a longer service life, which can reduce the cost of late maintenance and replacement, and are more suitable for large-scale, high-load industrial production scenarios.

9. Do you offer bulk packaging solutions of mixing tank manifolds for wholesalers?

We offer custom bulk packaging for mixing tank manifolds, made to fit the needs of wholesalers. The packing method can change based on order size, shipping distance, and storage needs. For large orders of standard manifolds, we use moisture-proof and rust-proof film, along with strong cartons or pallets. This makes stacking, storage, and shipping easier. Small parts are packed separately to stop them from hitting or scratching each other. Each box is clearly labeled with the model and quantity, so sorting is simple. We can also offer plain packaging or add your brand logo if needed.