Valves are essential plumbing products. They serve many vital functions, including regulating the flow of liquids within pipelines and turning on or off the liquid supply. The ball valve is a popular type of plumbing valve. We use ball valves in houses and industries. Due to their durability, they are buyers’ favorite choice. Let’s check out how a three-way ball works.

What is a Three Way Ball Valve?

The ball valve has a ball-shaped disk inside. The disc controls the flow of liquids and gasses in a plumbing system. The ball contains a hole in the center. When the valve is open, the hole lies parallel to the outlet. When the valve is closed, the hole moves opposite the initial state.

The three-way ball valve contains three openings and controls the flow of liquids and gases between three pipelines. These valves are perfect for multiple operations at a time, especially in industries. They can regulate flow and also work as a shut-off valve.

The openings of the three-way ball valve can be one inlet or two outlets. Depending on usage, it can be either two inlets or one outlet. The structure of the valve results in a steady flow across each opening. The number of ports does not affect the regulation of flow.

This valve’s multi-functional property makes it cost-effective. It eliminates the need to shut off the valve, as it can do both the job of regulation and shut off. It can even split the liquid and gas into two openings without disturbing the flow.

| Specifications. Product: T-port Three-way Ball Valve. Material: Stainless steel. Size: 1 Inch. Pressure: 200 Psi. Fluid Working Temperature: – 20°F to 410°F Applications: The product is Best for flow control of Water, gasses, oil, acids, and alcohols. |

Types of Three-Way Ball Valve:

Three-way ball valves come in different styles. Each type has a specific function and structure. Below are the essential types of three-way ball valves.

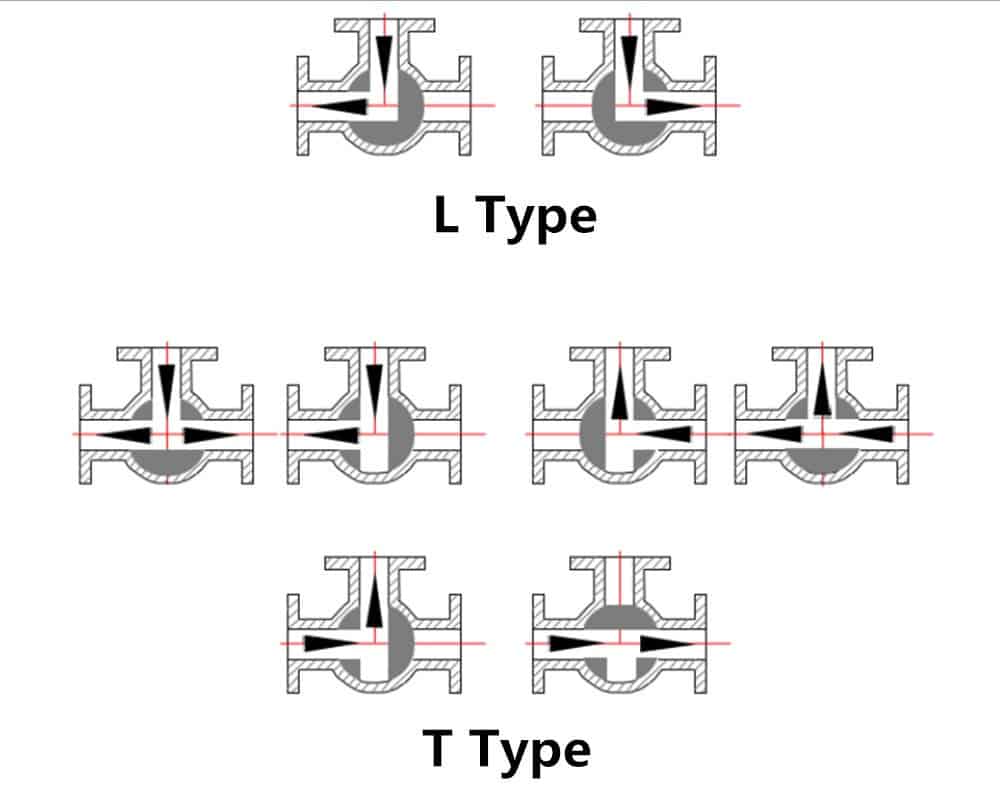

T–Port Three-Way Ball Valve:

The T-port valve is named so because of its shape. This valve can mix fluids from two inlets to one outlet and merge one channel into two outlets under certain conditions. Generally, they divide the flow of liquid and gas. The T-port three-way ball valve can mix and block the flow, allowing a streamlined flow.

These valves allow fluid passage from two openings and block the third one. The flow can be left, right, or straight at a 180-degree angle.

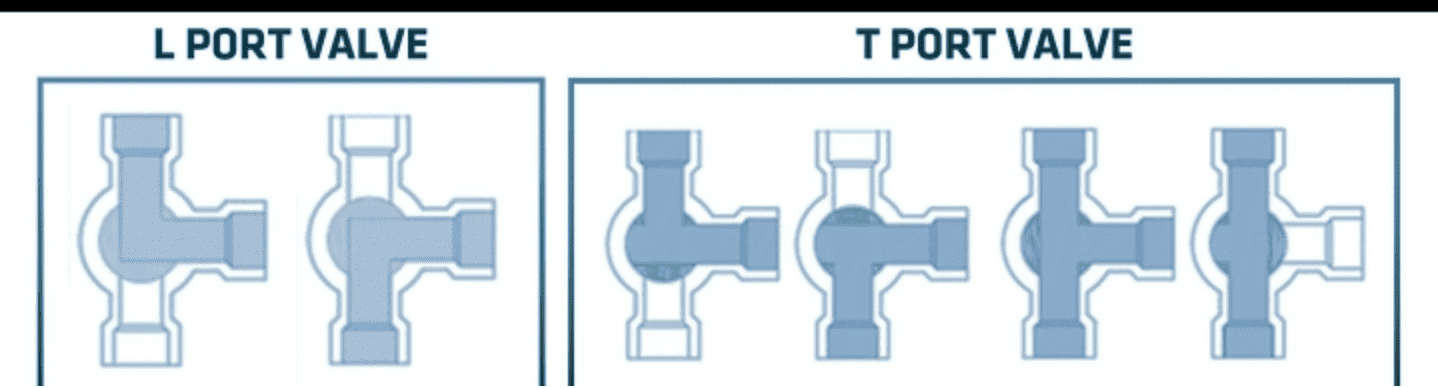

L-Port Three-Way Ball Valve:

The L-port ball valve has a shape that resembles the alphabet L. It allows the flow of liquids or gases from the inlet to one of the outlets. Unlike T-port valves, it works between two ports at a time. Because of its operating mechanism, it is also termed a Diverter Valve.

The L-port three-way ball valve can shut off or regulate the flow. The handle’s range is 90 degrees in one direction only. It applies perfectly when multiple sources are present and fluids are drawn to other pipelines. It commonly switches flow between two different pipes.

Forged Three-Way Ball Valve:

From Hydraulic and pneumatic systems

The valve body of a forged three-way ball valve is made from a single piece of metal shaped by forging. This manufacturing process involves heating and pressing the metal into shape, making the valve body more robust and durable.

The ball in the valve is usually made from stainless steel and designed to rotate inside the valve body. When the valve is closed, the ball blocks the flow of fluid through the valve. When the valve opens, the ball rotates, allowing the liquid to flow through one of the three ports.

Forged three-way ball valves are standard, where a single valve needs to control the flow between two pipelines. They are often used in the oil and gas industry. They are also applicable in chemical and pharmaceutical plants.

Floating Three-Way Ball Valve:

The “floating” in its name refers to the design of the ball, which “floats” between two sealing surfaces. The ball inside the valve floats between two seats or sealing surfaces. This allows the ball to move freely in response to changes in pressure and flow. This design is commonly used in lower-pressure applications and is less expensive than the designs used in higher-pressure applications.

Floating three-way ball valves are commonly used in various industries, including oil and gas, chemical processing, and water. They are often preferred over other valves because of their reliability and ease of use.

Applications of Three-Way Ball Vale:

The three-way ball valve has several applications, each suited to specific work. Here are the vital applications of three-way ball valves.

- The t-port three-way ball valves are used to control the flow of fluids in pipelines. We can turn the handle to pass liquids through both valve ports, allowing precise control over the direction and flow of liquids.

- We can use T-port ball valves to blend two different fluids and gases. In chemical processing systems, it can direct the flow of both media to one outlet.

- T-port three-way ball valves can divert liquids from one pipeline to another. They are common in the oil and gas industries for maintenance purposes.

- T-port valves can control the temperature of a liquid or gas by directing it to the cooling chamber. This requires fluids to be directed in a controlled manner toward heat-reducing sections.

- Three-way ball valves are applicable at points where repair is needed. They can isolate parts of pipelines and shut off the flow.

- Using a three-way ball valve can reduce the number of required valves in a system, leading to cost savings and a more straightforward, streamlined design. In a chemical processing plant, a three-way ball valve can direct the flow of different chemicals to different mixing tanks. It saves the hustle of having multiple valves for each tank, making the three-way ball valves more convenient and cost-effective.

Working of Three-Way Ball Valve:

A three-way ball valve is a type of valve with three ports or openings in the valve body. It works by using a rotating ball with a hole through the center that can be turned to control the fluid flow. The ball has a bore through the center through which the valve handle rotates. When the bore is aligned with one port, fluid can flow through the valve.

Here’s how each part of the three-way ball valve works.

The valve body:

The valve body is typically metal and has three openings or ports. Two ports opposite each other are the inlet ports, and the third port is perpendicular to the inlet ports and is called the outlet port.

The ball:

The ball is a spherical shape with a hole in the center. It is of the same diameter as the inlet and outlet ports. The valve handle rotates the ball to control fluid flow through the valve.

The valve handle:

The valve handle is attached to the ball and rotates the ball to align the hole with the desired port. The handle can be turned 90 degrees to open or close the valve fully. It can also be turned to an intermediate position to mix the fluids from the two inlet ports.

The seals:

The seals prevent fluid leakage around the valve stem and ball. The seals are typically made of a soft material, such as PTFE or rubber. They create a tight seal when compressed against the valve body.

The flow of fluid:

When we turn the valve handle to align the hole with one inlet port, the fluid can flow through the valve and out the outlet port. When we align the valve handle to the bore with the other inlet port, the fluid can flow through the valve and out the outlet port. When we turn the valve handle to an intermediate position, the liquid from both inlet ports can mix and flow out of the outlet port.

The T-port three-way ball valve allows three valves to open simultaneously. In the body, the valve mixes the liquids from two ports. The mixture can exit from the third port of the valve. Similarly, depending on the conditions, the situation can be vice versa.

The L-port Three-way ball valve’s flow direction can be changed by turning the handle 90 degrees. On every turn, the direction changes by sealing one port and opening the other. However, this type does not allow us to open three ports simultaneously.

The working mechanism of a three-way electric ball valve depends on the actuator. The actuator uses electric power to rotate the ball in the valve body. This causes the sources to align with the inlets and outlets and provides a passage for liquids and gases to pass through. Similarly, bringing the actuator back to its position closes the valve.

How to Install a Three-Way Ball Valve?

Installing a 3-way ball valve seems tricky, but it can be easy with the right tools and steps. Here’s a step-by-step guide on how to install a 3-way ball valve:

Materials you’ll need:

- 3-way ball valve

- Teflon tape

- Wrenches

- Pipe cutter

- PVC or metal piping

- Thread sealant

Step 1: Shut off the water supply. Before starting any plumbing project, turn off the main water supply.

Step 2: Cut the pipes. Cut the pipes where you want to install the valve. Be sure to leave enough space for the valve and fittings to be installed.

Step 3: Install the fittings. Install the fittings on both ends of the pipes. Use the appropriate type of fitting for your piping material.

Step 4: Apply Teflon tape. Wrap Teflon tape around the threads of the ball valve. It will help create a tight seal and prevent leaks.

Step 5: Install the ball valve. Screw the ball valve onto the fittings. Use a wrench to tighten the valve, but be careful not to over-tighten and damage the threads.

Step 6: Apply thread sealant. Apply thread sealant to the threads of the fittings and the ball valve. It will further prevent leaks and ensure a tight seal.

Step 7: Turn on the water supply. Turn the main water supply back on and test the valve for leaks.

Advantages of Using a Three-Way Ball Valve:

Three-way ball valves perform more than one function. They are economical and do more jobs at less cost. Below are the advantages of using three-way ball valves.

- Three-way ball valves offer less media resistance. It results in a more stable flow.

- They have a manageable and straightforward structure.

- As it has three ports, three-way the valve can mix incoming fluids.

- This valve offers a quick way to turn on or off the media supply. It is primarily a quarter-turn valve, so it can quickly be turned at 90 degrees.

- The three-way ball valve is a cost-friendly product because it can perform multiple functions at one valve’s cost.

- The valve has a reliable structure. Ball valves can perform their duty for a long time without wearing out.

- Three-way ball valves can undergo harsh pressure conditions. They often come with high-media temperature facilities.

- The three-way ball valve has a self-cleaning property. They wash away the impurities from the fluid and save the structure of the valve.

Conclusion:

Three-way ball valves are the best option for flow control across two Pipelines. They have excellent flexibility and a structure perfect for industrial use. Because they serve the function of more than one valve, they are cost-effective.

The working mechanism of this valve is very effective. You can purchase the right product by listing your requirements. This makes it easy to choose a long-lasting product.