Description

Three-way Ball Valves

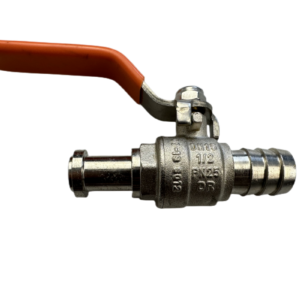

JX-0427

- Brass Three-way Ball Valve

- Product Features: Nickel-Plated Brass body and cover

- Size 1/2″ -2.”

- Forged brass and nickel-plated surface

- Normal work pressure;25 bar

- Max work temperature; -10-110℃

- Steel-level handle.

- Made from forged brass

- Sandblasted with nickel-plated finishing

- Cut off or shut off the flow

- Switch flow between two different sources

- Combine the flow from two various sources

- The alternate flow between two different destinations

- Divert flow coming from one source to another destination

- Split flow coming from one source between two outgoing destinations

- This post focuses on the fundamental design differences between L-pattern (L-port) flow and T-pattern (T-port) flow in three-way ball valves. I will also describe how to handle position and the range of handle rotation used to control flow through typical three-way ball valve designs.

What is a three-way ball valve:

A 3-way ball valve is a valve that has three openings or ports. Three, four, and five-way ball valves are applicable as multiport valves. A three-way ball valve is the most common multiport ball valve. A three-way ball valve connects a pipe or conduit to three ports or entrance points for gas or fluid flow (media). These ports are often described as one inlet and two outlet ports. We can say one outlet and two inlet ports, depending on the flow pattern through the valve. 3-way ball valves are popular. They provide a cost-effective and straightforward solution for managing shutdown—a flow channel in one valve body. The real benefit of this valve is its cost-effectiveness. This quality is due to its control and shut-off valve function.

How a 3-way ball valve works:

We have two types of 3-way ball valves that work differently from a standard ball valve. Let’s discuss how a 3-way ball valve works.

The L-pattern valve or divert valve shifts the flow from one port by twisting the handle. It is also possible when the actuator is turned 90 degrees. Assume that the bottom port is open and the left port is available. The valve diverts the flow to the proper output with a quarter turn anti-clockwise. This prohibits the movement of a transit medium in the opposite direction. It allows for a full 180-degree rotation. A 270-degree turn will also stop the press from moving. After a complete 360-degree rotation, the valve can return to its original position. Two of the three ports are operational at the same time. The primary function is to change the flow direction of the medium. As a result, the valve can have two shut-off positions and three flow options.

The T-pattern is a mixer valve because the media of two input flows combine within the T-pattern valve. On the other end, it’s leaving the valve. In a sense, each port from the three can open only once.

The T-pattern valve will function Likewise to the L-type valve as a diverter. All it takes is a quarter-turn of the handle. T-patterns can’t have a bubble-tight shut-off. Instead, they can limit flow to two ports or make it easier to pass through any or all three.

The T-pattern ball valve acts as a mixer. This mixer separates the media in two opposing directions. Like the two-way ball valve, its design allows the T-pattern to divide the flow. It can also produce a straight-through pattern. For the installed T-pattern ball valve, the standard port is still open. Turning it a quarter turn is the only method to deflect the flow. A 180-degree turn will not disturb the media flow.