Introduction:

Bronze is a mixture of both tin and copper. Although its composition varies, contemporary bronzes typically contain between 80 to 90% copper. Different types of bronze can be made by adding other elements. These include manganese, aluminum, nickel, phosphorus, silicon, arsenic, and zinc. Yet, all of these have their own set of appropriate qualities. Most bronzes are modified from the original alloy by adding one or more elements.

Physical Properties

| Density | 8800 kg m3 |

| Melting point | 880-1025°C |

| Electrical conductivity | 15% |

| Appearance/color | Reddish (mostly) |

| Yield strength | 450 MPa |

Grades of Bronze

Different bronze alloys are classified by their specific chemical makeup.

Alloy 954.

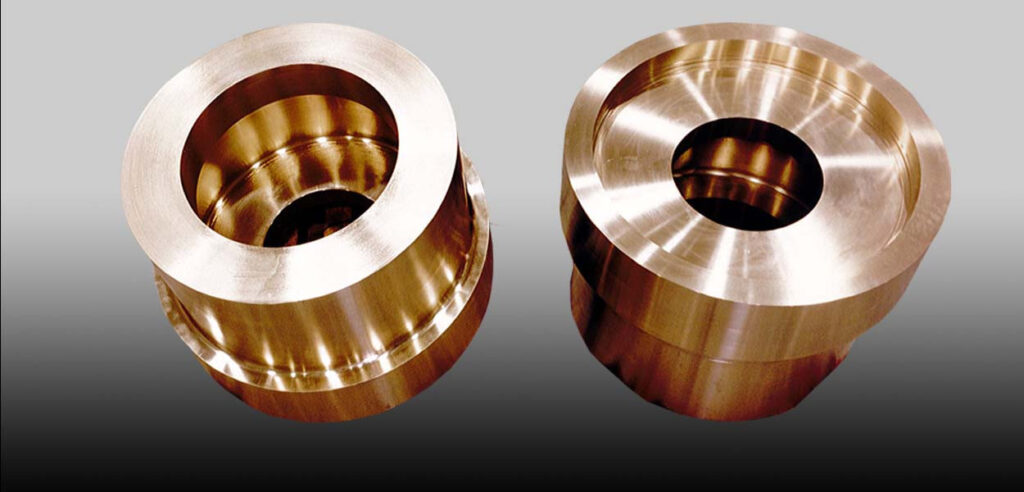

The aluminum bronze alloy has many applications, including industrial machinery and mounting.

Alloy 932.

This high-leaded tin bronze alloy is used to create non-pressure components, bushings, and washers.

Is Bronze Rust?

While bronze itself doesn’t rust, any exposed parts could eventually oxidize since copper is a constituent of bronze and oxidizes in a series of steps when exposed to air. Yet, bronze is a material that exhibits a wide range of oxidation states. In addition, the bronze’s copper helps structure a green patina that prevents further corrosion. It will rust if bronze comes into touch with sulfurous mixtures or chlorine.

The Bronze Age

The Bronze Age was entitled because bronze was the most complex metal people used then. China and India both went through the Bronze Age at the same time. Even in the Bronze Age, a few things were used to make meteoritic iron. However, the way iron was refined was terrific. The Iron Age began around 1300 BC and came after the Bronze Age.

Properties of Bronze

Hardness.

Although bronze is a superb sculpting material, it is also one of the most complex copper alloys. Its tenacity is proportional to the proportion of its original material and the new element it contains. It can endure pressures ranging from 35,000 to 119,000 psi, though. Manganese bronze is the most severe form of bronze. Yet, it can withstand the maximum allowable pressure.

Melting point

Unlike other copper alloys, bronze is resistant to melting. Over 2000 degrees Fahrenheit of heat are required to melt bronze. This remarkable bronze property provides insight into the resourcefulness of our ancient forbears. Amazingly, they were able to produce such a large amount of heat. They used primitive techniques to create bronze and could repeat the process.

Corrosion resistance.

With corrosion-resistant constituents, it is not surprising that bronze is also resistant to corrosion. Some of its varieties, such as Muntz metal, can withstand saltwater. This is ten times more corrosive than tap water. Instead, it forms a protective coating known as patina. This is typical of copper alloys.

Metal Supermarkets

What are Bronze’s Applications?

Since the discovery of steel and other metals with more suitable construction applications, bronze usage has declined significantly. Metallurgists who have spent a lifetime investigating the practically endless potentials of this metal have enabled bronze to become helpful in various other applications. Here are some of bronze’s most prevalent applications.

Art.

The most common application of bronze is in art, notably as a sculpting medium. It is the material of choice for metal artists because its remarkable feature allows it to expand as it cools slowly. Although heavy and dense, bronze is relatively easy to manipulate. It will enable sculptors to carve to their hearts’ content.

Construction.

Although bronze has been replaced by steel in various construction-related applications, it still has a role in some. For instance, numerous bridge components, wheels in worm drives, and bridge turntables are fabricated from a specific bronze alloy. Modern safety tools such as hammers, mallets, and wrenches are also constructed from bronze. These tools were initially made of steel, but bronze was substituted due to the risk of fire or explosion posed by the sparks steel can produce.

Machine Design.

Numerous machine parts, including spur gears, bushings, bearings, and valve components, are built of bronze. Yet, even valve guides in aircraft engines are ideally fabricated from bronze. It is because of high electrical conductivity, thermal resistance, and low-friction properties. Very few metals possess low-friction properties, critical when parts slide against one another at high speeds.

Manufacture method for bronze

1. Mining

Initially, most metals were gathered from rocks on the ground, in creek beds, and by prying prominent pieces from cliff faces. In their raw and natural state, copper and tin ore had to be mined from deeper within the earth as the demand for bronze soared.

Mine shafts were carved into hills around 4000 BCE in the Balkans, the earliest evidence of mining. We find evidence of onsite crucible smelting at copper mines in the Sinai Peninsula that dates back to 3800 BCE.

2. Smelting

The smelting process is required between the mining of raw ore and the casting of metal objects. Most metals do not exist in their purest form in their natural state. Other rock veins flow through it frequently, or the metal is embedded in other rocks as specks and flakes. A furnace is utilized to separate the d metal from the ore.

Copper requires temperatures of approximately 2000 degrees Fahrenheit in the furnace. At this temperature, copper melts and drips out of the surrounding rock. If the surrounding rock or other metals in the ore have a lower melting point than the ore, the ore will melt before the surrounding rock or metals. Bronze Age miners and metalworkers quickly discovered how to separate the various metals and their use, from jewelry to tools.

3. Pouring

After refining the copper, tin was added to create bronze. The bronze was then poured into sand molds and allowed to cool. This technique, called casting, was utilized to manufacture bronze swords, brooches, knives, and pins.

The bronze can be polished and fashioned into a variety of shapes. It might be melted down and transformed into something else. Due to its durability, it was beneficial for crafting peasant implements and warrior weapons. Three methods of casting exist:

3.1. Sand Casting

Sand casting is the earliest of the three processes. This process involves constructing a pattern in the shape of the desired component. The design is, after that, placed in a flask containing sand. The pattern is removed after adding a binding agent to solidify the sand and curing the mold.

Pour molten bronze into the remaining hollow space to form the necessary shape. After the metal has cooled, the sand mold is removed, leaving only the sand casting. This casting can be sold in its current state or undergo extra finishing processes. One of the benefits of sand casting is the ability to create distinctive shapes that are impossible with traditional procedures.

3.2 Centrifugal Casting

Commonly, cylinder-shaped castings are produced using centrifugal casting. In centrifugal casting, a cylinder-shaped mold is employed. The mold is then rotated or spun around its axis at a preset speed. The wall thickness of casting is determined by the amount of material inserted during pouring. Due to the characteristics of centrifugal casting, the inner diameter of the item must always be round.

Most metal impurities are less dense than the metal itself. Throughout the casting process, these contaminants will concentrate in the inner modulus of the casting and can be eliminated. Consequently, the casting contains fewer impurities.

3.3 Permanent Casting

Bronze is cast in a continuous length using the continuous casting method. Pouring molten bronze into a mold gives it its shape. A cut-off determines the length of the casting saw, not the mold. In continuous casting, gravity is utilized to help move the metal along. This casting process begins high above the ground and requires much space.

Continuous casting has a lower material loss rate and a better production rate than other techniques. Yet, this approach results in generally superior casting quality. This is because of the reduced solidification time and more uniform material properties.

Bronze Alloys

Aluminum bronzes

Aluminum bronzes are a class of copper-based alloys with chemical and mechanical properties unmatched by any other series. They consist of 5 to 12% aluminum and up to 6% nickel and iron. Manganese and silicon are also included in aluminum bronzes. They have equivalent strength to low-alloy steels and excellent corrosion resistance, especially in seawater and similar environments, where they frequently surpass stainless steel sheets.

The aluminum in the alloys reacts with atmospheric oxygen to form a thin, corrosion-resistant alumina (aluminum oxide) layer, a barrier against corrosion for the copper-rich alloy. They are available in cast and wrought forms.

Aluminum Bronze Applications

For handling saltwater, acidic mine waters, non-oxidizing acids, and industrial process fluids, aluminum bronze alloys are utilized in marine hardware, shafts, and pump and valve components. They are also used in heavy-duty sleeve bearings and machine toolways. Castings of aluminum bronze have excellent corrosion resistance, high strength, tensile strength, and wear resistance. Yet, there is no requirement to mention their perfect casting and welding properties.

Common Aluminum Bronze Alloys

Here is the list of common aluminum bronze alloys;

C95800: Suited for marine applications with optimal resistance to marine water corrosion.

C95200: It is a highly malleable material with effective corrosion-resistant properties.

C95900: It offers compressive strength and higher hardness. Yet, it employs die inserts, seats, valve guides, draw dies, wear plates, gears, and forming rolls.

C95400 offers extraordinary strength, tensile strength, and high yield and is exceptionally resistant to deformation and wear.

Properties of aluminum bronze alloy C95400

| Mechanical Properties | Physical Properties |

| Tensile strength (min) – 85ksi | Density – 0.269 lb/in3 at 68°F |

| Yield strength (min) – 32ksi | Meeting point (liquids) – 1900°F |

| Brinell hardness (min) – 170 Bhn | Specific gravity – 7.5 |

Nickel Aluminum Bronze: C95500

C95500 is aluminum bronze; like other types, it also contains nickel. Aluminum bronze with a nickel content is among the hardest non-ferrous metals available. The alloy has relatively high elongation. Yet it also has yield strength, hardness, and compressive strength. Heavy-duty, high-shock, high-impact applications will significantly benefit from this superior bearing material. The alloy is corrosion-resistant to salt water. It also has weldability, good machinability, and heat resistance.

Chemical Composition

| Cu% | Fe% | Al% | Mn% | Ni% |

| 78 | 3.0 – 5.0 | 10 – 11.50 | 3.50 | 3 – 5.50 |

Mechanical Properties

| Machinability rating | 50% |

| Brinell hardness | 208 |

| Expansion in 2 in. or 50 mm min, % | 10 |

| Tensile strength, min | 95 ksi (655 MPa) |

| Yield strength | 42 ksi (290 MPa) |

Physical Properties

| Properties | Metric | US Customary |

| Melting point (solid) | 1038 °F | 1900 °F |

| Melting point (liquid) | 1054 °F | 1930 °F |

| Specific gravity | 7.53 | 7.530 |

| Density | 7.53 gm/cm3 @ 20°C | 0.272 ib/in 3 @ 68 °F |

| Electrical conductivity | 0.049 MegaSiemens/cm @ 20 °C | 8% IACS @ 68 °F |

| Thermal conductivity | 41.9 W/m @ 20 °C | 24.2 Btu/sq. ft/ft hr/@ 68 °F |

Fabrication Properties

| Joining Technique | Suitability |

| Coated Metal Arc Welding | Good |

| Gas Shielded Arc Welding | Good |

| Oxyacetylene Welding | Nor recommended |

| Brazing | Fair |

| Soldering | Good |

Material Properties of Nickel Aluminum bronze

Corrosion Resistance and Strength

Nickel aluminum bronze is distinctive from other alloys due to its excellent strength and resistance to corrosion. The alloy’s corrosion resistance is much improved due to the addition of nickel, which blocks the action of seawater. The result is an alloy that is resistant to corrosion even in the presence of high humidity and high temperatures. Because of its high strength and resistance to corrosion, it is ideal for use in marine applications such as boat hulls, propellers, and ships.

Ductility and Malleability

Nickel aluminum bronze’s malleability is another excellent quality. It may be manipulated into several forms without cracking or fracturing. Because of its malleability, it is frequently used when high levels of machining accuracy are required. The alloy also possesses high elasticity, which allows it to be pulled into thin wires or sheets without compromising its strength or other qualities. As a result, it can be used in places where thicker cables wouldn’t fit, such as in electrical or plumbing installations.

Nickel Aluminum Bronze: C95800

Chemical Composition

| Cu% | Fe% | Al% | Mn% | Ni% | Pb | |

| Nominal | 81.0000 | 4.0000 | 9.0000 | 1.0000 | 4.5000 | 4.0000 |

| Min/Max | 79 | 3.5 – 4.5 | 8.5 – 9.50 | 8 – 1.5 | 4.0 – 5.0 | 3.5 – 4.5 |

Physical Properties

| Properties | Metric | US Customary |

| Melting point (solid) | 1030 °F | 1910 °F |

| Melting point (liquid) | 1060 °F | 1930 °F |

| Specific gravity | 7.64 | 7.64 |

| Density | 7.64 gm/cm3 @ 20°C | 0.276 ib/in 3 @ 68 °F |

| Electrical conductivity | 0.041 MegaSiemens/cm @ 20 °C | 7% IACS @ 68 °F |

| Thermal conductivity | 36 W/m @ 20 °C | 20.8 Btu/sq. ft/ft hr/@ 68 °F |

Fabrication Properties

| Joining Technique | Suitability |

| Machinability Rating | 20 |

| Coated Metal Arc Welding | Good |

| Gas Shielded Arc Welding | Good |

| Oxyacetylene Welding | Nor recommended |

| Brazing | Fair |

| Soldering | Good |

Nickel Aluminum Bronze: C95900

C95900 Aluminum Bronze is a strong metal with excellent corrosion resistance. Gears, worm drives, valve guides, and valve seats are some of this alloy’s many heavy-duty mechanical and structural applications. C95900 is a tremendous heavy-duty bearing alloy but is sensitive to misalignment and unclean lubricants. It works best when used against hardened steel shafts with a high degree of precision machined into both the shaft and the bearing.

Chemical Composition

| Fe% | Al% | Mn% | Ni% |

| 3.0 – 5.0 | 12 – 13.50 | 1.50 | 0.50 |

Applications

- Drill jig bushings

- Dies

- Pilot bushings

- Wiping blocks

- Inserts

- Forming rolls

- Die rings

Silicon Aluminum Bronze

Silicon is nearly the ideal alloying metal due to its ease of pouring, visually appealing surface properties, and high corrosion resistance. Additionally, silicon fits excellently into the bronze alloy. Even if only about 6 percent of the bronze alloy is composed of silicon, this gives bronze the self-lubricating properties required to be easily shaped or cast into intricate designs.

Aluminum bronze’s superior mechanical capabilities are combined with silicon’s self-lubricating qualities in silicon aluminum bronze. It can be substituted by C63000 nickel aluminum bronze if necessary. Free-machining, anti-galling, and anti-seizing attributes can all be found in C64200 silicon aluminum bronze.

Silicon-Al-Bronze Application

Silicon aluminum bronze is commonly used for various purposes, including but not limited to valve guides, safety belt assemblies, pole line hardware, valve and pump components, cams, hooks, forged machined components, and landing gear parts. Silicon aluminum bronze is used in various fields, including aerospace, oil & gas, automotive, electrical, marine, etc.

Uses

Landing gear components, strut bushings, rock bit bearing bushings, valve guides, cams, pole line hardware, safety belt assemblies, valve and pump components, hooks, and forged machined components are popular applications for silicon aluminum bronze. Aerospace, oil and gas, automotive, electrical, and marine industries, among others, all utilize silicon aluminum bronze.

Silicon aluminum bronze: C64200

To get the durability and corrosion resistance of aluminum bronze alloy with the machinability of bearing bronze, you won’t find a better option than C64200 Silicon Aluminum Bronze. The ideal alloy is C642 silicon aluminum bronze. C642’s tensile strength is between 75 and 90 ksi, with a machinability value 60. Size uniformity is enhanced in C642 since it is a wrought alloy rather than with similarly cast items. The decreased machining losses and increased uniformity contribute to a lower total product cost.

Chemical Composition:

| Copper | 91.20% |

| Aluminum | 6.30 – 7.60% |

| Nickel | 0.25% |

| Lead | 0.05% |

| Iron | 0.30% |

| Zinc | 0.50% |

Application by Kind: C64200

The corrosion-resistant engineering alloy C64200 Silicon Aluminum Bronze (like copper but more robust). Typically, it is produced in rod form (either round, hexagonal, or octagonal). After that, it cuts to the exact length the customer requires. Even now, C64200 remains one of the most often used alloys for valve stems.

Gears, pole line hardware, nuts, marine hardware, valve bodies and components, wellhead components, etc., are some products that benefit from its use. Because of its use in a variety of industrial applications, C64200 Silicon Aluminum Bronze is used by numerous businesses.

Application by Kind: C63600

C63600 Silicon Aluminum Bronze may be easily forged and worked in hot and cold temperatures. There are three primary uses for it. The electrical industry creates cold-headed nuts, cable connectors, and other pole line hardware. They are used in producing the industry’s valve parts and nuclear power services. Bolts and other screw machine components are also made from C63600.

Phosphor Bronze:

C51000 (also known as UNS P510) is the most common type of phosphor bronze, and it has a composition of around 5% tin and 0.5-0.8% phosphorus by weight. Zinc, manganese, aluminum, antimony, nickel, lead, iron, and silicon are other elements that could be present in trace amounts. The exact composition is function-dependent; anti-friction bearings, for instance, may contain up to 2% lead or graphite for lubrication purposes.

Composition:

| Tin | 4.2 – 5.8% |

| Copper | 93.4 – 95.32% |

| Iron | 0.10% (max) |

| Phosphorus | 0.030 – 0.35% |

| Lead | 0.05% (maximum) |

| Zinc | 0.30% (maximum) |

Phosphor bronze characteristics

- Phosphor bronze is a copper-tin-phosphorus alloy.

- Because of its excellent tensile strength and low coefficient of friction, it is perfect for bearings and gears.

- Phosphor bronze is corrosion-resistant, making it appropriate for use in marine situations; it is also nonmagnetic and possesses excellent electrical conductivity.

- It is coldly workable but not hot workable.

- Phosphor bronze is weldable but cannot be soldered.

- A range of formulations is available, depending on the desired qualities.

- The most common phosphor bronze alloy comprises 95% copper, 4% tin, and 1% phosphorus and is designated C51000.

- C52100 (92% copper, 5% tin, 3% phosphorus), C54400 (85% copper, 10% tin, 5% phosphorus), and C61400 (80% copper, 15% tin, 5% phosphorus) are also popular alloys.

- Phosphor bronze is utilized in numerous applications, such as electrical components, springs, gears, and bearings.

Uses of phosphor bronze

- Phosphor bronze is a copper and tin alloy containing between 0.5 and 11% phosphorus.

- Phosphorus enhances the alloy’s strength and hardness, making it suitable for several applications.

- The alloy is also utilized to fabricate electrical components, including wires and connectors.

- Phosphor bronze occasionally creates musical instruments such as cymbals and bells.

Physical Properties

| Alloy Name | C5210 | 52240 | C51111 | C5102 | C5191 | C5212 |

| Poisson’s Ratio | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 |

| Electrical Conductivity | 12 | 10 | 17 | 15 | 14 | 13 |

| Modulus of Elasticity | 110 | 100 | 110 | 110 | 110 | 110 |

| Specific Gravity | 8.80 | 8.78 | 8.87 | 8.86 | 8.83 | 8.80 |

| Alloy Name | Composition | Features |

| C51111 | Cu-4Sn | Bend formability and spring properties |

| C5102 | Cu-5Sn | Bend formability and spring properties |

| C5191 | Cu-6Sn | Bend formability and spring properties |

| C5212 | Cu-8Sn | Bend formability and spring properties |

| C5210 | Cu-8Sn | High bend formability and spring properties |

Manganese Bronze

Additionally, manganese can make bronze complex and robust. This enables bronze to handle high-load applications and low-speed, which were formerly among its few limitations. However, manganese’s muscular bearing strength makes bronze a non-heat-treatable metal, necessitating special lubricants in applications utilizing manganese bronze.

While each kind of bronze has a distinct set of attributes due to its additional element, they all have some characteristics. These characteristics define the diversity of bronze metal applications.

Why Select this Material: Manganese Bronze Material Properties?

• Depending on the alloy’s composition, tensile strengths between 60,000 and 110,000 psi are easily accessible.

• Certain manganese bronze alloys can be used as bearings cautiously because manganese bronze and steel do not get along very well. Seizures can occur under high loads and speeds, and wear is quick. Accurate alignment and enough lubrication are both crucial.

Chemical Composition:

| Copper | 60 – 68% |

| Aluminum | 3.0 – 7.5% |

| Manganese | 2.5 – 5.0% |

| Tin | ≤0.2% |

| Iron | 2 – 4% |

| Zinc | 25% |

Weakness and Resistance

Manganese bronze is frequently specified over other bronzes because of its outstanding durability. Manganese gives it superior resistance to wear and corrosion compared to most other bronzes. Despite not being heat-treatable, it has an excellent strength profile. It is resistant to seawater corrosion (but not as much as silicon bronzes) and can be warm or cast upon request. Being one of the most challenging bronzes to manufacture, its primary drawback is its cost. In addition, it must be reliably maintained for optimal performance, as abrasive conditions will compromise the alloy’s strength.

Manganese Bronze: Physical Properties

This is a statistical breakdown of a specific manganese bronze (alloy UNS C86300) to get an idea of alloying components by weight:

| Copper | 60 – 68% |

| Aluminum | 3.0 – 7.5% |

| Manganese | 2.5 – 5.0% |

| Tin | <0.20% |

| Iron | 2 – 4% |

| Zinc | 25% |

Manganese bronze always has a good amount of zinc and a small amount of manganese and tin). Manganese bronze has a density of about 7.7 g/cm3, a yellow-brown brass color that gets darker over time. Most alloys called manganese bronzes can’t be strengthened with heat, but they are solid even though they can’t be supported. It has no magnetic properties and about 80% of the electrical conductivity of pure copper. It is also resistant to corrosion and wear. It is hard to braze, solder, gas shield arc weld, and carbon arc weld, but it can be welded with a coated metal arc. It is usually hard to machine, but it can respond better to machining stresses.

Nickel Silver Bronze

Nickel silver is a kind of bronze, although its name does not contain the word. It is made from bronze, tin, and nickel. Moreover, despite its name, this bronze does not include silver. Silver refers only to the silvery hue of the metal, which is not characteristic of bronze. This enormous change in appearance is one of the primary reasons why identifying bronze products or items can be challenging. This is because customers are used to perceiving bronze as a brown metal.

Nickel Silver Bronze: C97600

The cast bronze alloy known as C97600 Nickel Silver Bronze, or dairy metal or dairy bronze has a high machinability value of 70. C97600 is known as the dairy metal due to its widespread application in producing valves, fittings, and gears for the dairy industry. Once known as ASTM Alloy 11A, this term has been discarded in preference of a newer designation for the material.

Uses:

Plumbing industry: sanitary fitting

Industrial: Valves and pumps

Marine industry: Marine furniture

Chemical Composition

| Copper | 63 – 67% |

| Zinc | 3.0 – 9% |

| Manganese | 1% |

| Tin | 3.5 – 4.5% |

| Iron | 1.5% |

| Pb | 3 – 5% |

Fabrication Properties

| Joining Technique | Suitability |

| Machinability Rating | 70 |

| Coated Metal Arc Welding | Nor recommended |

| Gas Shielded Arc Welding | Nor recommended |

| Oxyacetylene Welding | Nor recommended |

| Brazing | Excellent |

| Soldering | Excellent |

Physical Properties

| Properties | Metric | US Customary |

| Melting point (liquid) | 1143 °C | 2089 °F |

| Melting point (solid) | 1108 °C | 2027 °F |

| Specific gravity | 8.9 | 8.9 |

| Density | 8.9 gm/cm3 @ 20°C | 0.321 ib/in 3 @ 68 °F |

| Electrical conductivity | 0.029 MegaSiemens/cm @ 20 °C | 5% IACS @ 68 °F |

| Thermal conductivity | 26.6 W/m @ 20 °C | 13 Btu/sq. ft/ft hr/@ 68 °F |

Nickel Silver Bronze: C97800

Chemical Composition

| Copper | 64 – 67% |

| Zinc | 1 – 4% |

| Nickel | 24 – 27% |

| Tin | 4 – 5.5% |

| Iron | 1.5% |

| Pb | 1 – 2.5% |

Fabrication Properties

| Joining Technique | Suitability |

| Machinability Rating | 60 |

| Coated Metal Arc Welding | Nor recommended |

| Gas Shielded Arc Welding | Nor recommended |

| Oxyacetylene Welding | Nor recommended |

| Brazing | Excellent |

| Soldering | Excellent |

High Leaded Tin Bronze Alloys

The lead concentration of these alloys ranges between 7% and 30%. Because of the lead component, tin bronzes with a high lead content are free-cutting and retain excellent thermal conductivity and lubricity. The high-leaded tin bronzes are suited for bearing applications where lubrication boundary loss is possible. These alloys operate exceptionally well in harsh situations where extraneous matter, such as dirt and other foreign materials, may be present. Due to their malleability, high-lead alloys can encase foreign materials, thereby protecting a mating component’s wear surface, such as a shaft.

Function:

The primary purpose of high-leaded tin bronze alloys is to enhance their machinability. Its longevity in service and resistance to corrosion and abrasion have made them industry standards. Wire and cable connectors, electrical plug-type connectors, doorknobs, screws, nuts, anti-corrosion bushings, rolling mill bearings, and countless other items need connectors.

Different classes of high-leaded tin bronze

C93400

Uses Thrust bearings, corrosion-resistant castings, slide bars, bearings, pump impellers, and bushings.

Forms/Shapes: Flats, rectangular bar, structural shape, hex, square, plate, bar stock, bloom, anode, mil stock, semi-finished.

Chemical Composition

| Copper | 82 – 85% |

| Zinc | 0.80% |

| Nickel | 1% |

| Tin | 7 – 9% |

| Iron | 0.20% |

| Pb | 7 – 9% |

| Al | 0.005% |

| S | 0.8% |

Physical Properties

| Properties | Metric | US Customary |

| Modulus of elasticity in tension | 75800 MPa | 11000 ksi |

| Specific heat capacity | 377.1 J/kg @ 20°C | 0.09 btu/ib @ 68 °F |

| Specific gravity | 8.86 | 8.86 |

| Density | 8.9 gm/cm3 @ 20°C | 0.32 ib/in3 @ 68 °F |

| Electrical conductivity | 0.07 MegaSiemens/cm @ 20 °C | 12% IACS @ 68 °F |

| Thermal conductivity | 58.2 W/m @ 20 °C | 33.6 Btu/sq. ft/ft hr/@ 68 °F |

C93900:

The UNS C93900 alloy is a tin bronze copper casting alloy with a high lead content. Phosphor bronze, aluminum bronze, tin bronze, silicon bronze, architectural bronze, and manganese bronze are other bronze alloys.

Chemical Composition

| Element | Content (%) |

| Copper | 76.5 – 79.5% |

| Zinc | 1.5% |

| Nickel | 0.80% |

| Tin | 5 – 7% |

| Iron | 0.40% |

| Pb | 14 – 18% |

| P | 0.050% |

Mechanical Properties

| Properties | Metric | Imperial |

| Machinability (UNS C36000 (free-cutting brass) = 100 | 80 | 80 |

| Brinell hardness | 63 | 63 |

| Elastic modulus | 117 GPa | 16969 ksi |

| Tensile strength | 220 MPa | 31900 psi |

| Poisson’s ratio | 0.34 | 0.34 |

| Yield strength (@strain 0.500 %) | 150 MPa | 21800 psi |

C93600

Forms/Shapes: Flats, rectangular bar, structural shape, hex, square, plate, bar stock, bloom, anode, mil stock, semi-finished.

Uses:

Industrial: Wrist pin bushings, steel mill bushings, spacer bushing for pumps, sleeve bushings, seal, rolling mill bearings, piston pin, pump sleeves, locomotive bearing parts, rod bushing, flow monitor valve, hydraulic gland seals, electric motor bearings, bushings for lubrication/corrosion/pressure, main bearings for presses, cam bearings for diesel engines, deep well pump line shaft bearing.

Chemical Composition

| Element | Content (%) |

| Copper | 79 – 83% |

| Zinc | 1% |

| Nickel | 1% |

| Tin | 6 – 8% |

| Iron | 0.20% |

| Pb | 11 – 13% |

| S | 0.08% |

| Al | 0.005 |

Physical Properties

| Properties | Metric | US Customary |

| Melting point (liquid) | 1143 °C | 1720 °F |

| Melting point (solid) | 1108 °C | 1550 °F |

| Specific gravity | 9 | 9 |

| Density | 9 gm/cm3 @ 20°C | 0.325 ib/in 3 @ 68 °F |

| Electrical conductivity | 0.064 MegaSiemens/cm @ 20 °C | 11% IACS @ 68 °F |

Nickel Tin Bronze

Nickel tin bronze includes spinodal, nickel gear, and leaded bronzes. The common application includes pump bodies, cams, worm gear, worm wheel, etc.

Nickel Tin Bronze: C94700

Physical Properties

| Properties | Metric | US Customary |

| Melting point (liquid) | 1027 °C | 1880°F |

| Melting point (solid) | 904 °C | 1660 °F |

| Modulus of elasticity in Tension | 15000 ksi | 103400 MPa |

| Specific gravity | 8.86 | 8.86 |

| Density | 8.86 gm/cm3 @ 20°C | 0.32 ib/in 3 @ 68 °F |

| Electrical conductivity | 0.07 MegaSiemens/cm @ 20 °C | 12% IACS @ 68 °F |

Fabrication Properties

| Joining Technique | Suitability |

| Machinability Rating | 30 |

| Coated Metal Arc Welding | Good |

| Gas Shielded Arc Welding | Good |

| Oxyacetylene Welding | Fair |

| Brazing | Excellent |

| Soldering | Excellent |

Forms/Shapes: Flats, rectangular bar, structural shape, hex, square, plate, bar stock, bloom, anode, mill stock, semi-finished.

C96900 Nickel Tin Bronze (Bushing Bronze System and Spindal Bearing)

This high-performance alloy can withstand heavy loads and operate in challenging circumstances. A suitable bronze alloy with low friction and non-corrosive properties is accessible in the market.

Chemical Composition

| Element | Content (%) |

| Zinc | 0.50% |

| Nickel | 14.50 – 15.50% |

| Tin | 7.50 – 8.50% |

| Mn | 0.05 – 0.30% |