FAQs of Water Hammer Arrestors For Washing Machines

What do Water Hammer Arrestors For Washing Machines do?

The core function of the washing machine water hammer absorber is to absorb the instantaneous pressure fluctuation generated in the pipeline (i.e., water hammer phenomenon) when the washing machine inlet valve is suddenly closed. It protects pipes and valves inside washing machines and domestic water supply systems, and mitigates the impact of prolonged water hammer, which can lead to loose pipe joints, leaks, or valve damage. It can also reduce noise from water hammer.

What is the core application scenario of the washing machine water hammer absorber?

The washing machine water hammer absorber most often needs to use the scene, which is the washing machine inlet valve, which frequently starts and stops the pipeline system. Suitable for residential, commercial laundry, high-pressure water supply environment, more suitable for water supply pressure fluctuations, low demand for water supply areas.

How many water hammer cycles can it withstand?

In a routine test scenario, water hammer absorbers undergo at least 1000 water hammer shock cycles to verify basic reliability, and some industry specifications require no more than 10% degradation in product performance after 1000 consecutive operations. Professional testing equipment can simulate up to tens of thousands of impact cycles to verify the fatigue limit of the product under extreme conditions. Comply with commercial-grade product indicators and international standards, such as those in Europe and America.

Does a washing machine need 1 or 2 water hammer absorbers? (Cold/hot water piping is required)

In most scenarios, it is recommended to install one cold and one hot water pipe, respectively. Most domestic and commercial washing machines on the market are connected with cold and hot water pipes at the same time, and the water inlet valve of the washing machine belongs to a quick-closing valve. When working, the cold and hot water pipes will produce a water hammer phenomenon due to frequent opening and closing of the valve. Only one washing machine is a single-water cooled model, only connected to the cold water pipe, so only one needs to be installed on this cold water pipe, accurately solving the problem of water hammer of a single-way water supply.

What is the difference between maintenance-free and maintainable products? How to choose?

The maintenance-free type adopts a sealed structure, has a high initial cost but can be used stably for 5-10 years, and is suitable for large-scale batch matching, no professional maintenance team or concealed installation scenarios; Maintainable type has detachable parts, needs regular maintenance and replacement of worn parts, lower initial procurement cost and longer maintenance life, suitable for high-frequency heavy load, special working conditions or large-scale venues with fixed maintenance team, etc. B2B procurement can be flexibly selected according to installation scale, maintenance capacity, and service conditions.

What is the flow adaptation range for different interface sizes (e.g., 3/8″, 1/2″, 3/4″)?

For new residential areas and apartments, 1/2″interface is preferred for batch matching, which is suitable for the flow range of about 0.8 – 1.5 m³/h and most standard washing machines; 3/4″ interface is required for industrial laundry plants and large hotel laundry rooms, and the flow range is about 1.2 – 2.5 m³/h; 3/8″interface can be selected for centralized procurement of small residential accommodation and mini washing equipment, 2.0 – 4.0 m³/h.

Does the product support parallel/series installation? Is it suitable for centralized water supply scenarios for multiple washing machines?

The product supports parallel/series installation. For scenarios involving multiple washing machines, it is more secure to prioritize the combination of “parallel connection of main pipes + single installation of branch pipes.” The main pipeline should deal with the overall water hammer impact through parallel absorbers, and then install small absorbers in the cold and hot water branch pipes of each washing machine, respectively, to adapt to the conditions of high-frequency start and stop and large flow of centralized water supply.

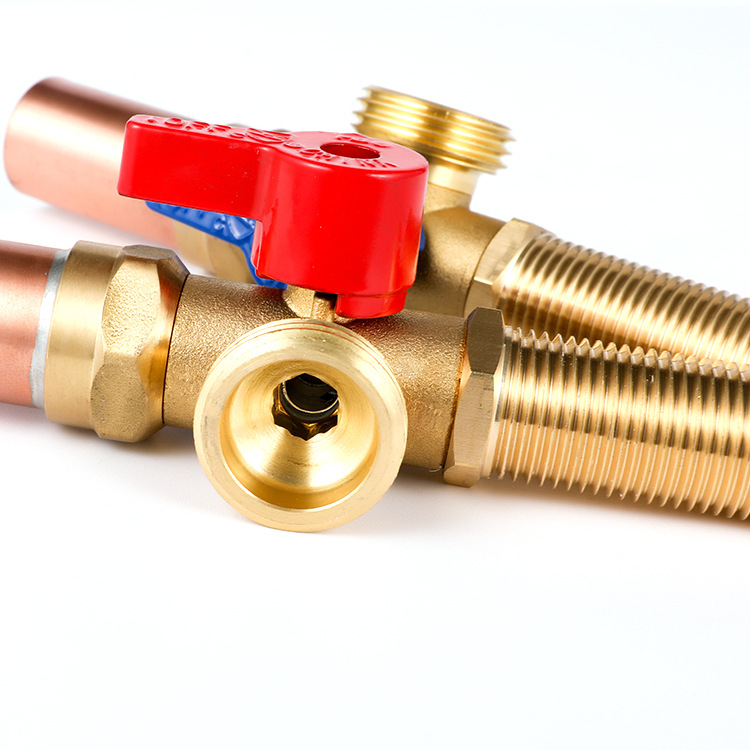

Does the product have anti-corrosion and anti-rust functions?

Most of the water hammer absorbers suitable for washing machines have anti-corrosion and anti-rust functions. In addition to the primary material, the core sealing parts of the product will also be matched with anti-corrosion materials to help ensure the overall anti-rust effect. For example, some products use EPDM, O-rings, and other seals; these rubber materials are resistant to water corrosion and will not chemically react with metal parts to cause corrosion.

How do you handle urgent orders?

According to the customer’s procurement needs, we have the production support capability for emergency projects, which can optimize the production schedule and ensure the delivery efficiency of emergency orders. If there is a clear delivery deadline, we need to inform you in advance of the specific time node. We will start the special production process and urgent promotion to ensure that the specified deadline is met to complete the product delivery.

Why should I choose Plumberstar as my valve supplier?

Excellent product quality, with core components selected from 316L stainless steel, lead-free brass, and other high-quality materials. Some products can withstand extreme temperatures ranging from -196 ℃ to 450 ℃, and are certified to API 6D, NSF/ANSI 61, and other international standards. We have accumulated nearly 20 years of OEM/ODM experience, our products have covered 45 countries and regions around the world, and we are a trusted partner.