Description

Water Hammer Arrester for Washing Machine

JX-0418

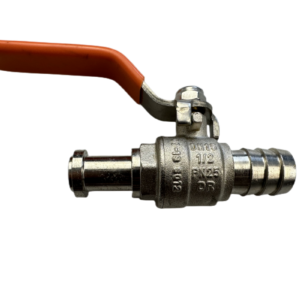

1/2″ Pex x 3/4″ MHT Valve

Valve with Copper Water Hammer Arrester 1/2″ Pex x 3/4″ MHT Left Blue Handle

1/2″ Fit x 3/4″ MHT Right Red Handle.

Valve with Stainless Steel Water Hammer Arrester 1/2″ Pex x 3/4″ MHT Left Blue Handle

1/2″ Fit x 3/4″ MHT Right Red Handle.

Valve with Plastic Water Hammer Arrester 1/2″ Pex x 3/4″ MHT Left Blue Handle

Water hammer arresters are designed for washing machines and other plumbing systems. They help to minimize the water hammer effect, which can cause a loud banging noise as water rushes through pipes. Water hammers occur when a valve or faucet is shut off suddenly, resulting in a shock wave of pressure throughout the piping system. The arrester absorbs this shock wave and allows water to flow smoothly. This reduces the noise from the water hammer and helps prevent damage to the pipes from sudden pressure changes.

Installing a water hammer arrester is an easy way to improve your washing machine’s performance, reduce noise levels, and protect your home’s plumbing system from costly repairs due to damaged pipes caused by high-pressure shocks. The device is pretty simple to install, often requiring only essential tools such as pliers and screwdrivers for installation into existing plumbing systems.

Causes of Water Hammer

A water hammer is a loud banging sound that may occur when valves control the water supply close suddenly. It is also referred to as “hydraulic shock” and can be caused by several factors. The most common cause of water hammer is when a rapid closing of the valve causes a pressure wave within the pipes, resulting in loud banging against the pipe walls or other objects. It can also be caused by air trapped in the pipelines, an increased temperature of flowing liquid that creates increased pressure fluctuations, or high-velocity piping systems.

Though a water hammer doesn’t typically cause serious damage, it can become a nuisance if not addressed quickly. For this reason, installing a water hammer arrestor on washing machines and other similar appliances helps to absorb excess kinetic energy from closing valves and reduce or eliminate noise and vibration associated with hydraulic shock.

Benefits of an Arrestor

Water hammer arresters are becoming increasingly popular for washing machine installations in homes and businesses. A water hammer arrester is a device that protects the plumbing system from damage caused by sudden pressure changes, such as when the washing machine quickly fills or empties. Installing an arrester can save you time, money, and headaches by helping to prevent costly repairs due to ruptured pipes or leaks. Not only do these useful devices help protect your plumbing, but they also provide many other benefits.

The most obvious benefit of installing a water hammer arrester is improved safety, as it helps to reduce the risk of flooding due to ruptured pipes or leaking valves. A bonus is that they also help reduce noise levels in your home, often eliminating those annoying banging sounds associated with washing machines.

Types of Arrestors

A water hammer arrester is an important part of any washing machine setup. It helps to protect the plumbing system from high-pressure surges that sudden stops in the water flow can cause while washing laundry. Without this protection, pipes can burst or become damaged due to these pressure spikes. Several types of arrestors available on the market provide varying levels of protection from water hammering.

The most basic arrester type is an air chamber, which consists of a sealed tube with an open end connected to the main line between the faucet and shutoff valve. This device allows excess pressure to dissipate into its chamber before reaching other areas in the plumbing system.

Installing an Arrestor

Water hammer arrestors are essential equipment for any washing machine setup. This device is designed to absorb the water pressure shock when the washing machine starts and stops. Installing an arrestor will provide significant benefits to the homeowner regarding safety, efficiency, and increased longevity of their washing machine.

The installation process for an arrestor is relatively straightforward. The first step is to locate the hot water supply line leading into the house, usually at a point near where it enters from outside or under a sink cabinet. Then, using a pipe wrench or adjustable pliers, loosen the lock nut at the end of this line before attaching one end of the arrestor. Next, attach another section of copper tubing between this outlet and your washing machine inlet valve, ensuring it fits securely with no leaks.

Maintenance Tips for Water Hammer Arresters for Washing Machines

Regular maintenance of your water hammer arrester is key to keeping it in top condition. It’s essential to check the unit every few months and ensure no signs of wear or damage. Here are some tips on how to properly maintain your water hammer arrester:

First, inspect the unit and ensure all connections are secure and free from debris or leaks. Also, check the pressure gauge regularly and adjust it as needed to prevent water hammering. Second, replace any worn-out parts with genuine replacements available at your local hardware store. Finally, always use a professional plumber when making repairs or replacing parts, as they will have the necessary knowledge and experience.

Conclusion

Water Hammer Arrester for Washing Machine is an important device that can help protect your washing machine and pipes from the damaging effects of a water hammer. A water hammer arrester allows a sudden burst of pressure to escape, preventing significant damage or destruction of your plumbing system. Installing a water hammer arrester is highly recommended for any home or business with a washing machine.

After learning about the importance and function of a water hammer arrester, it’s clear that this device should be installed in any home or business with a washing machine. The installation process is pretty straightforward and relatively inexpensive compared to the cost of repairs due to water damage caused by high-pressure bursts.