Description

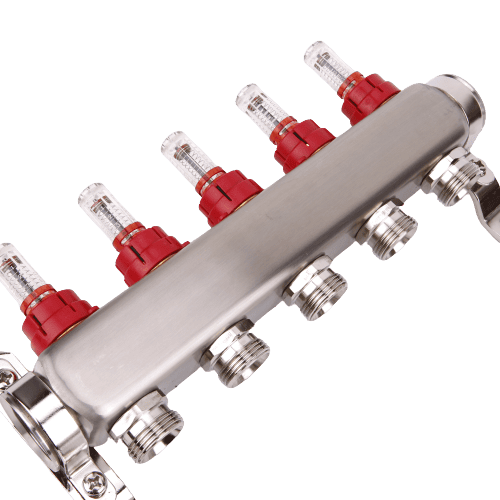

Underfloor Heating Manifold

JX-0702

- Stainless steel Manifold

- Stainless steel 304

- Polishing surface treatment

- Operating temperature;-10-110℃

- Working pressure; Max 16 bar

- Connection thread; 3/4″&1/2″ loop

- Hard sealing with a flexible fitting connection.

- Manufactured from corrosion-resistant and durable Stainless Steel to last for life

- Compatible with any PEX tubing – no special adapters needed

- Simply mount the manifold on brackets and connect the valves and PEX tubing

- The manifold connects the heat source – a boiler, heat pump, or other – with the water underfloor heating circuits, regulates the incoming water temperature via the Mixing Unit, and distributes this warm water throughout the floor circuits for an energy-efficient heating system.

- It is made from High-Quality Stainless Steel to last for life.

- An automatic air vent (air eliminator); Float air vent purges the air out of the radiant heat system. The air vent cap is included for pressure testing purposes.

- Drain valves; Both drain valves feature a 3/4″ male garden hose connection for convenient draining/filling of the system. Caps included.

- Mounting brackets with bolts; Heavy-duty design and custom engineered to offset the manifold from the mounting surface for easy access and installation of PEX tubing.

- 1/2″ PEX Manifold Adapters- free with manifold’s purchase. Compatible with all types of PEX tubing

- You should install a heating manifold in a central area. It will reduce your installation cost of tubing. Manifolds have High reliability. It is also low in maintenance cost. The installation cost depends on the location of a manifold. During planning, the system designer needs to consider access first. The designer should be qualified enough. Experienced and professional underfloor heating installers should install underfloor heating manifolds. It would be best if you placed the manifold in an accessible area for future servicing and commissioning. The underfloor and the bottom of the manifold should be between 200 millimeters. Clearance should be 75mm above and at least 50mm on either side. A heating manifold might use only one tubing, though more than ten tubing lines can sometimes be used. For more than an average number of connections, manifolds can be made in the job sector, or You can also order with the required specifications. You can also find ready-made manifolds in the market with the needed number of connections. You can install manifolds with spare connection ports if you need enlargement later. You can also crop out the unused connection points if not required. The two units are often placed together. Only one bracket can support both units. The floor area can get warmed to between 25°C and 28°C. It can provide an even distribution of heat. It can maintain only a little higher temperature than room temperature. Among many other UFH systems, this is a unique feature of the heating manifold.

Working Principle of Heating Manifold

Underfloor Heating is not a new technology. The principles go back to Roman times. In Europe, it is very much popular now. In some countries, 70% of new heating installations are manifolds.

The Heating Manifold links with the heat source with a boiler connecting the water with underfloor heating circuits. It regulates the temperature of incoming water via the mixing unit. It also allocates hot water throughout the floor circuits. It provides efficient Heating for energy. Underfloor heating circuits are always filled and removed with water. It happens after a successful installation & connections. The primary heating circuit of the manifold creates a connection with a heat source. Heat sources can provide demanded water temperature. It never gets overheated. The mixing unit will deactivate the system at that time.

A heating manifold is made of two parts where one is a flow manifold, and another is a return manifold. The flow manifold has a flow meter. It indicates the flow rate achieved in each loop. There is a valve in the return bar to control the loop. An actuator valve controls the opening/closing. It responds to the call from a room thermostat.

Close the valve on the supply manifold (clockwise). Lift and turn a setting ring, graduated 0.5–5. It will balance each underfloor heating loop. Now press the ring down. The valve will then open. There might be flowmeters instead of supply valves. Adjust the flowmeters by corresponding to the calculated ring. Setting the ring helps to prevent any loop from opening too far. The filling valve of the supply line can reduce or stop the flow in the bypass.

Common Under Floor Heating Manifold Problems

There might arise a few situations causing the heating manifold not to work. These include:

- Air in the system. Blow the air off the system using the air vent, which can be placed on the flow bar of the manifold. It will rectify any air-caused problems.

- Incorrect or imbalanced flow rates. One can adjust it using the flow meters on the flow bar. The correct rate will depend on the design of the system.

- Blockage in the system. There might be blockage by any physical item. In this case, flush the system through. It will free the debris.