Description

|

3 Way Shower Diverter Valve

The 3 Way Shower Diverter Valve is the core control accessory used to switch the water flow path in the bathroom shower system. Its core purpose is to accurately switch the water flow direction by rotating the handle or button, allowing for a single or combined water discharge mode. Control, such as directing the mixed water flow of hot and cold water to the top spray separately, to the handheld shower separately, or to supply the top spray and the handheld shower at the same time to meet different shower needs; It can effectively prevent water leakage and water leakage, ensure the stability of water outlet; adopt standard thread or sleeve connection mode, adapt to most specifications of shower pipeline and terminal interface.

|

|

|

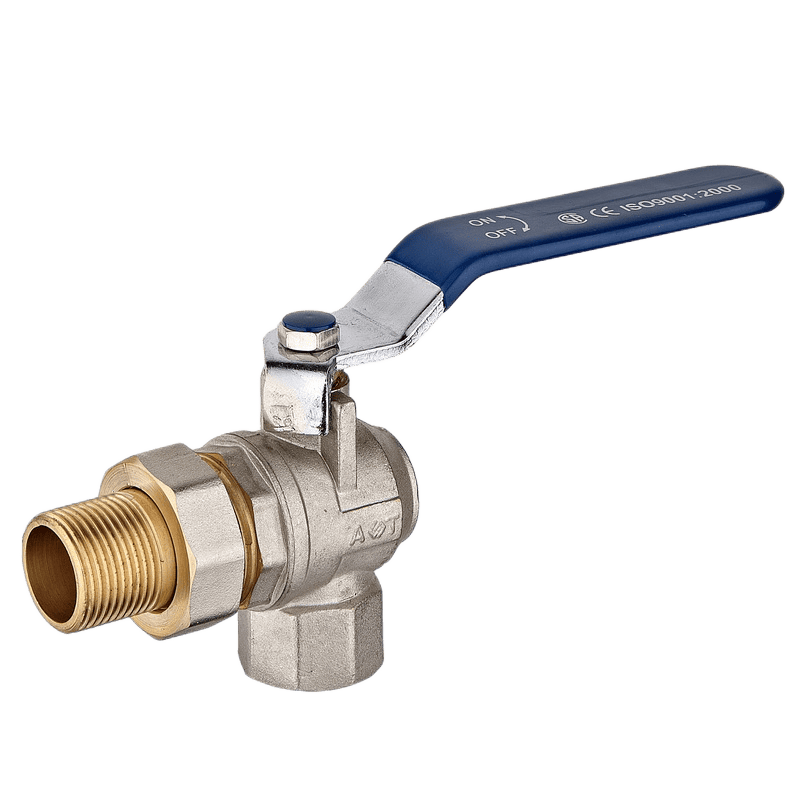

Washing Machine Shut-off Valve A washing Machine Shut-off Valve is a special control accessory that connects the wall water supply pipe and the washing machine inlet in the household appliance’s water supply system. The primary function of a washing machine shut-off valve is to precisely control the water inlet into the washing machine. It rotates the handwheel quickly to open or shut off the water inlet. It ensures not only a stable water supply during the normal operation of the washing machine but also cuts off the water source when the washing machine is stopped, repaired, or not used for an extended period, thus preventing the burst of water pipes. Water leakage accidents due to loose joints, etc., reduce water waste. Use a standard thread connection; it is compatible with most washing machine inlet hoses and wall water supply pipe specifications.

|

|

|

90 Degree Brass Angle Valve It’s a brass material, chrome-plated polished 90 degrees angle valve, is a bathroom and kitchen pipeline system to connect the wall water supply pipe and faucet, shower, washing machine, water heater and other terminal sanitary ware/equipment dedicated control accessories, its core use is to control the terminal equipment water inlet on and off and water flow regulation, 90 degrees angle structure accurately matches the wall water pipe and terminal equipment installation angle, reduce the pipeline layout space occupation, By rotating the handwheel, you can quickly switch the water source or fine-tune the water flow size, easy to operate.

|

|

Brass Closet Spud Elbow for Bathtub Waste

It’s a special transition fitting that connects the bathtub drain outlet to the drain pipe in the bathroom’s pipeline system. It is widely used in residential bathrooms, hotel bathrooms, apartment bathrooms, and other scenes. The core purpose is to pass through a specific angle. (usually 90 degrees) elbow structure, to achieve accurate docking of bathtub sewage outlet and wall or ground sewage pipe, to solve the problem of turning, adaptation, and sealing of bathtub sewage path, installation through sealing gasket or thread fastening to achieve a tight connection, ensure smooth sewage, avoid hair, debris accumulation caused by blockage.

|

|

|

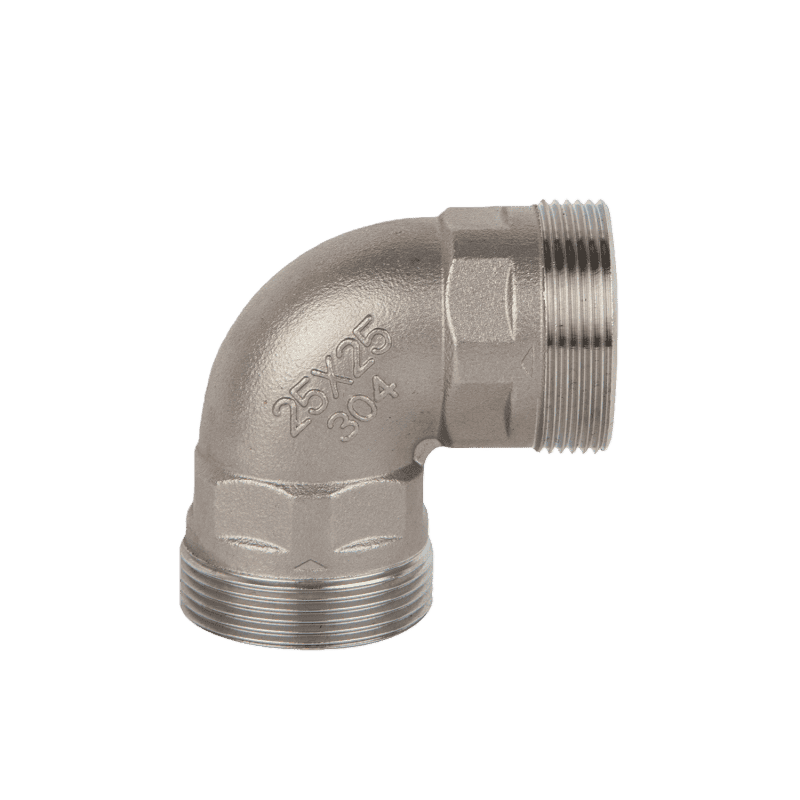

Right Angle Ball Valve

It’s a type of ball valve featuring a 90° right-angle structure. It is a special accessory for changing the direction of water flow and realizing on-off control in the pipeline system. It is widely used in scenes with limited installation space. Its core purpose is to achieve simultaneous pipeline steering and fluid on-off control. The 90-degree right-angle structure enables the completion of pipeline corner connections without the need for additional elbows, thereby saving installation space and simplifying pipeline layout.

|

|

Brass Vertical Foot Check Valve The brass vertical foot check valve is the core protective fitting used to prevent medium backflow in a fluid transmission system. Its core purpose is to achieve one-way flow control of fluid through a vertical installation structure and foot-fixing design, preventing medium backflow from causing idle running of the water pump, system pressure fluctuations, or equipment damage. It adopts a valve disc and spring linkage structure inside. When fluid flows forward, pressure pushes the valve disc open, ensuring smooth transmission of the medium. When the fluid stops or flows in reverse, the disc closes automatically under the spring force and reverse pressure, blocking the backflow channel. The foot design facilitates the valve’s firm installation at the bottom of the pipeline or at the equipment interface.

|