FAQs of Stainless Steel Mesh Filter Floor Drain

1. What is the structure of a stainless steel mesh filter floor drain?

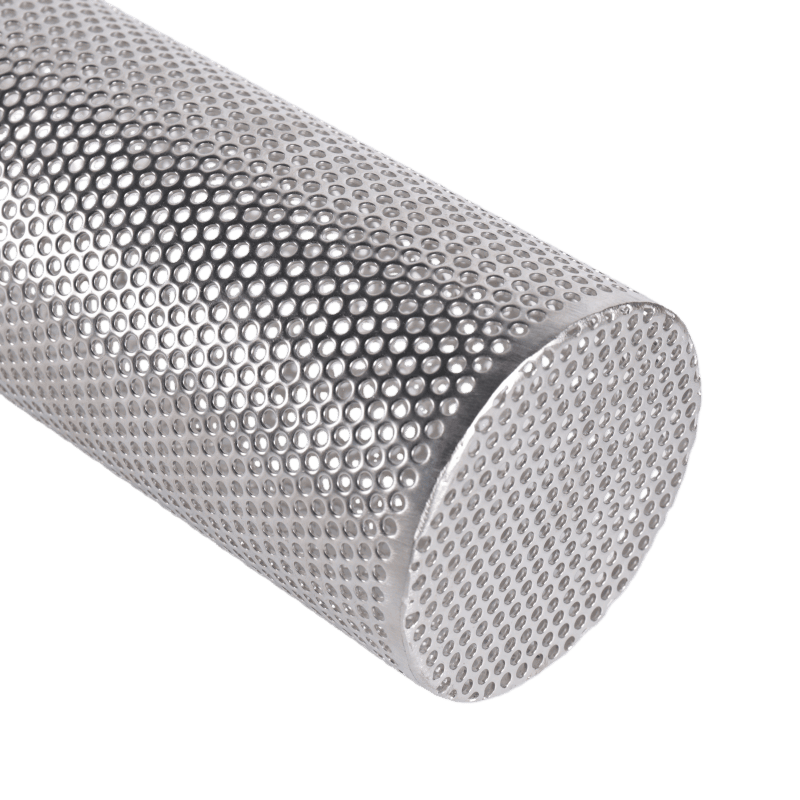

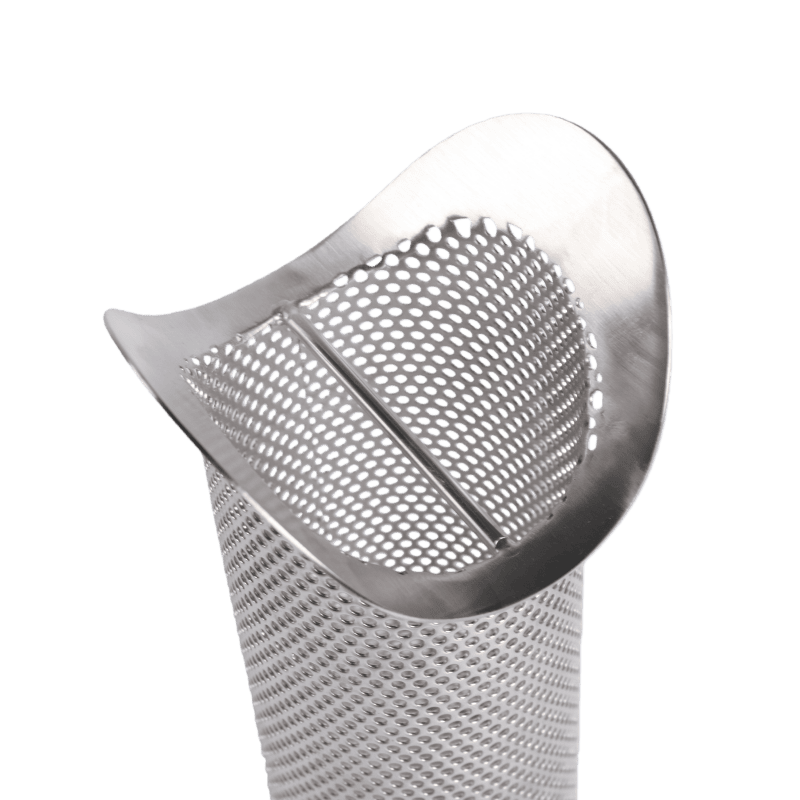

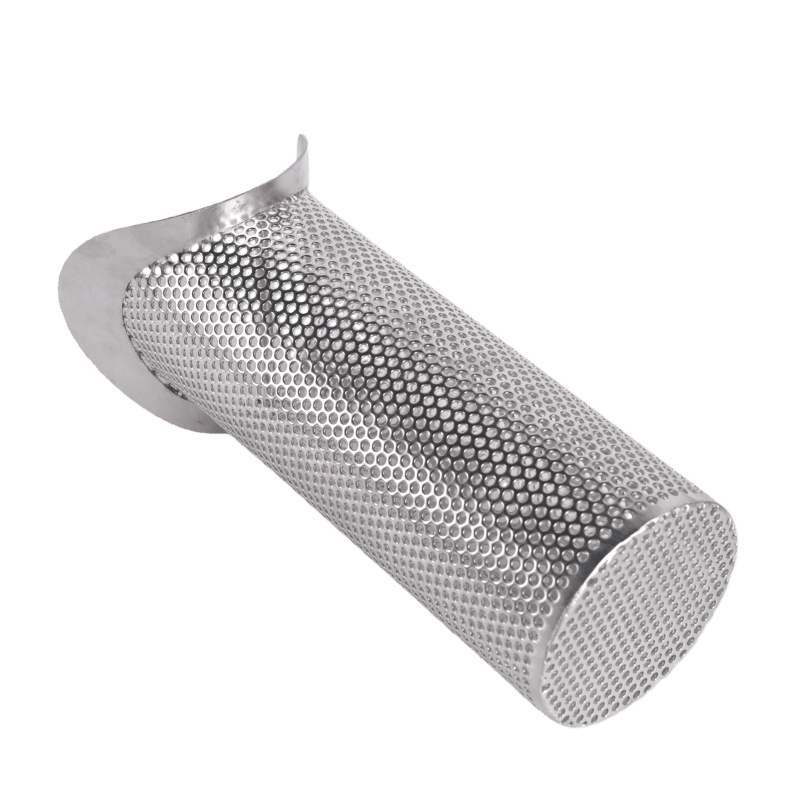

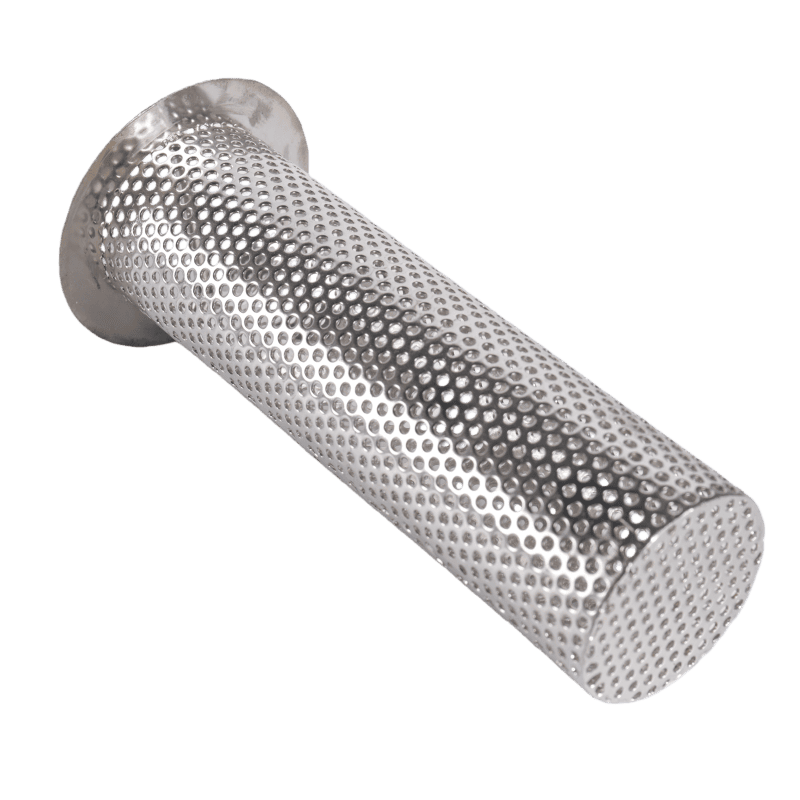

The core structure includes a 304/316L stainless steel main body, a high-density mesh basket filter, a deodorizing sealing core, and an anti-slip panel. Plumberstar uses an integrated stamping process, so the main body has no weld joints. The mesh basket filter utilizes a multi-layer woven mesh with optional openings ranging from 1 to 5 mm. Filtration efficiency reaches at least 98%, which effectively traps hair and debris. The deodorizing core combines a silicone seal with a gravity rebound design. It seals tightly and helps prevent odors from recirculating up the drain. The top panel is available in brushed or mirror finish. Its anti-slip coefficient is ≥0.8, meeting international safety standards and making it safer to use in wet areas.

2. What is the filtration accuracy and drainage flow of the stainless steel mesh fitter floor drain?

The Plumberstar stainless steel basket filter floor drain is designed to strike a balance between filtration and drainage, making it effective in various real-world situations. The details below show how it does that.

- Filtration accuracy

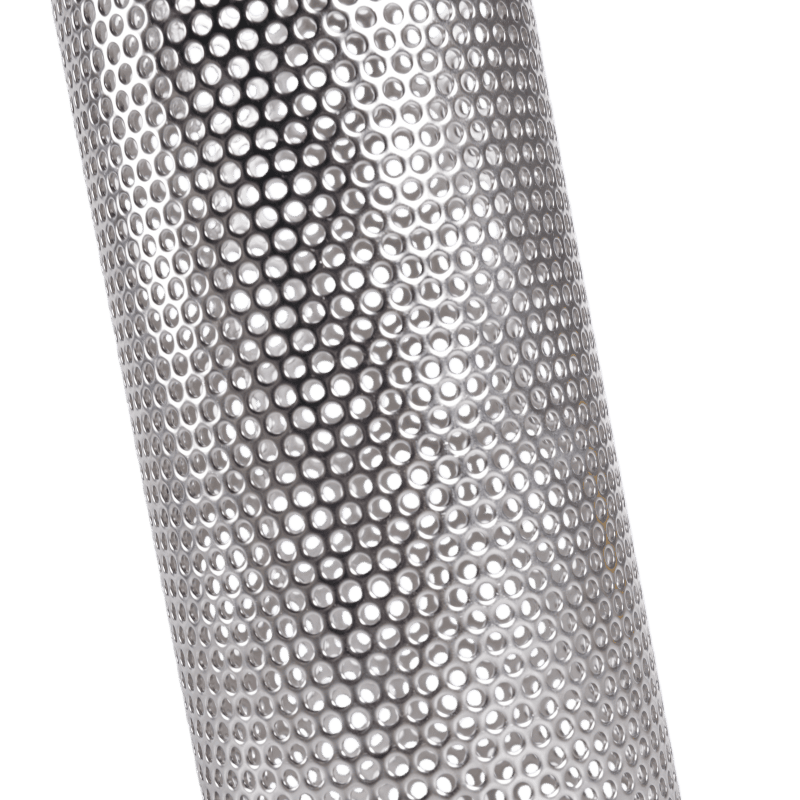

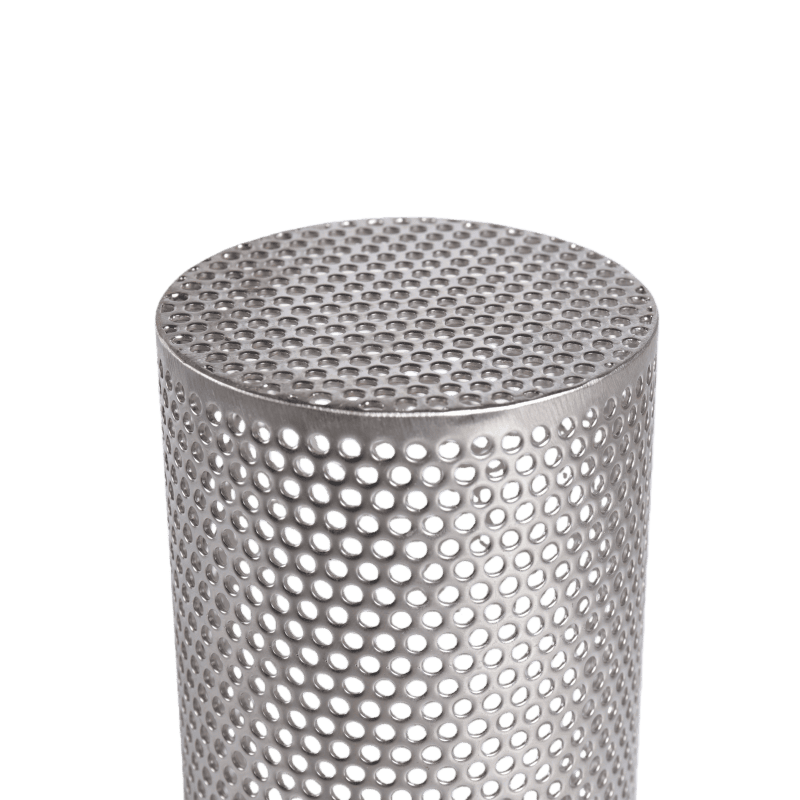

There are four common mesh options: 1 mm, 2 mm, 3 mm, and 5 mm. The basket is made from 304 stainless steel with a multi-layer woven mesh, utilizing wire diameters of approximately 0.3–0.5 mm.

Each mesh size fits a clear use case.

1 mm is for places like hospitals and food factories, where very fine debris needs to be stopped. 2 mm works best in bathrooms, where hair and fibers are the main issue. 3 mm suits kitchens, catching vegetable scraps and small food waste. 5 mm is used in swimming pools, basements, or utility areas to block stones and larger particles.

Unlike many competitors, Plumberstar offers a wide range of choices, and our woven mesh boasts a tensile strength of ≥500 MPa, enabling it to maintain its shape and resist deformation easily. The filtering performance stays stable over time.

- Drainage flow rate

Drainage capacity is clearly defined by pipe size and is well above standard requirements.

DN50 (2 inch): ≥1.2 L/s, with peak test results up to 1.4 L/s. This is far higher than the 0.3 L/s minimum in GB/T 27710-2020 and better than the typical 1.0 L/s seen in similar products. It works well for bathrooms and balconies, with no water buildup in showers. DN75 (3 inch): ≥2.5 L/s, suitable for kitchens and small pools, where water needs to drain quickly. DN100 (4 inch): ≥4.0 L/s, designed for large pools, basements, malls, and other high-flow areas.

3. How does the mesh fitter floor drain deodorize, anti-blocking, and insect-proof?

The Plumberstar stainless steel net basket filter floor drain uses a triple-protection integrated design that combines deodorization, anti-blocking, and insect prevention in one system. Its key performance features and competitive advantages are outlined below.

- Deodorization performance

The drain is equipped with a food-grade silicone sealing core that combines a gravity-rebound mechanism with a water-seal structure. For dry applications, it also incorporates magnetic adsorption and mechanical closure. The water seal depth is ≥50 mm, and the seal leakage rate is ≤0.01 m³/h, significantly outperforming the typical competitor level of about 0.05 m³/h.

- Anti-blocking performance

A high-density stainless steel basket filter with optional apertures from 1 mm to 5 mm achieves an interception rate of ≥98%, accurately capturing hair, food residues, and other debris. Thanks to an optimized internal flow channel, the effective drainage diameter is about 30% larger than that of many competing products. The basket can be removed without tools in around 30 seconds, making cleaning fast and simple. In real use, the clogging rate is ≤0.1%, far below the industry average of 1%–2%, and even under high-flow conditions, the drain discharges water quickly without pooling.

- Insect prevention performance

Insect control is ensured by a dual physical barrier formed by the filter basket and the sealing core. Compared with the single-layer protection, the smallest mesh size of the basket is only 1 mm, and when closed, the sealing core fits tightly against the valve body with no gaps, delivering 100% insect-blocking effectiveness. This design avoids issues such as insect intrusion after basket damage or leakage through sealing gaps.

4. Can a stainless steel net basket filter floor drain be customized the size?

Plumberstar stainless steel basket filter floor drain offers full-size customization. You can flexibly adjust core dimensions — panel size, inlet diameter, and installation depth. Just match it to your foreign trade order requirements, pipeline specs, or decoration designs.

- Here are the specific customization options. Square panels can be made in any size. The size range is from 50×50mm to 300×300mm. The regular standard sizes are 100×100mm and 150×150mm. Circular panels support customization. The size range is from φ50mm to φ300mm. They work well for special decorative styles, such as invisible floor drains and strip drainage setups. Panel thickness can be adjusted from 3mm to 8mm. Thickened panels (≥6mm) have a bearing strength of ≥ 1.0 MPa. They’re ideal for high-traffic areas like shopping malls and garages, preventing deformation and sinking.

- Inlet diameter customization. Main diameters cover DN50 (2 inches), DN75 (3 inches), and DN100 (4 inches). You can also get special diameters from DN40 to DN150. These adapt to different pipeline flow needs. For example, DN40 suits small balconies, while DN150 is for large pools or basements with high drainage demands. Custom diameters still guarantee great drainage efficiency. A DN150 custom model has a flow rate of ≥6.0L/s, far exceeding national standards. No waterlogging risk at all.

- Installation depth customizationRegular installation depth is 80mm to 150mm. You can customize ultra-thin models (≥50mm) for shallow pipe scenarios after pipeline shifting. Or deepened models (≤300mm) for deep water seal and odor-proof needs. The water seal depth is ≥50mm, meeting the odor control standards of the Ministry of Housing and Construction. For faulty pipeline setups, you can get lengthened floor drain cores. This prevents water from leaking into the mortar layer and causing wall mold.

5. How to track the production progress of the mesh filter floor drain?

Plumberstar offers full-process visual tracking for stainless steel basket filter floor drain batch orders. From contract signing to final delivery, customers can follow every key step and stay updated in real time.

- Production Schedule Confirmation

Within three working days after the contract is signed, we provide a clear production schedule. This schedule is sent via email and serves as a reference for order tracking.

- Ongoing Production Updates

During production, we send progress updates twice a week by email. These include workshop photos, such as material inspection, valve body processing, and basket filter weaving. We also share short videos of key tests, such as deodorizing performance and drainage flow checks, along with high-quality data, including salt spray test results and dimension inspection reports. This allows customers to clearly see the progress of their order.

- Fast Response to Issues

If any unexpected issue occurs, such as material delays or equipment problems, we will inform the customer within two hours. We share the solution and adjust the plan at the same time. Any delay is controlled within 48 hours to avoid affecting the customer’s delivery schedule.

- Logistics Tracking After Shipment

After shipment, we immediately provide the tracking number by email. We support DHL, FedEx, UPS, and other major carriers. Packing lists and scanned shipping documents are shared at the same time. We also assist customers in tracking the shipment until delivery. If there are delays, damage, or other logistics issues, our team follows up and helps resolve them throughout the process.

6. What are the payment terms of the mesh fitter floor drain?

For international orders of Plumberstar stainless steel basket filter floor drains, we offer flexible payment options to suit different cooperation models and reduce cross-border trade risks.

Payment Methods

We support two widely used payment options:

- T/T (Telegraphic Transfer)

This follows the standard industry practice of 30% deposit + 70% balance before shipment. Production starts after the deposit is received. Before delivery, customers can check product quality through video inspection or photos. The remaining balance is paid after confirmation, ensuring fund security for both parties.

We accept sight letters of credit issued by major international banks. This option is suitable for large-volume orders or first-time cooperation, as it provides strong payment security and lowers trade risk.

For long-term partners with annual order volumes of 5,000 pieces or more, we also offer price locking and flexible billing terms. This helps improve cash flow and supports stable, long-term cooperation.

7. Why choose Plumberstar mesh fitter floor drain?

The core competitiveness of Plumberstar manufacturer is embodied in the three dimensions of “process, protection, and adaptation”:

- Integrated stamping process, no welding breakpoints (Most competitors are welded and are easy to corrode and leak), and the strength of the valve body is increased by 40%.

- Triple protection design (high-precision filtration + silica gel deodorization + anti-skid panel), the anti-blocking, deodorizing, and anti-skid effects are far superior to those of competitors only do basic filtration.

- Strong scenario customization capabilities, with size and material options available, enable customization of up to 300 pieces. The delivery cycle is ≤25 days, making it suitable for small and medium-sized orders in foreign trade. In contrast, competitors generally have a customization threshold of more than 1000 pieces.

8. Can the mesh fitter floor drain handle heavy foot traffic without damage?

Our stainless steel mesh filter floor drain’s resistance to trampling is ensured through a combination of high-strength materials and a reinforced structural design, as outlined below.

Reinforced Structural Design for Impact and Load Resistance:

Mortise-and-tenon welded structure. The stainless steel panel and filter basket are connected using a mortise-and-tenon welding method. This creates a stable, integrated structure that resists deformation and loosening under repeated pressure.

Even load distribution. The reinforced stainless steel panel works together with the internal filter to distribute pressure evenly when stepped on. This reduces point stress and prevents dents or surface deformation.

Secure filter-to-body connection. The tight mechanical connection between the filter basket and the drain body prevents displacement or loosening, even under heavy loads or continuous trampling.

9. What technical data is required to start an OEM project for a mesh fitter floor drain?

1. Product Base & Structure — Technical Data

1.1 Core Dimensions & Design Files

Deliverables

Plumberstar will provide complete 2D engineering drawings and 3D model files, clearly indicating all key structural dimensions, including but not limited to: Floor drain nominal diameter (standard options: DN50, DN75) Body wall thickness, Stainless steel filter pore size (typically 4–5 mm, based on filtration requirements)

Mesh panel size and geometry

Tolerance Requirements

All critical dimensions shall be clearly marked with corresponding tolerance ranges to ensure production consistency and assembly accuracy.

Surface Finish Specifications

Surface treatment shall follow Plumberstar’s standard processes, such as brushed (satin) or polished finishes.

Surface roughness must be explicitly defined, with Ra ≤ 0.8 μm, to prevent visual defects and ensure uniform appearance.

1.2 Material Details

Base Material Specification

The drain body and filter components shall be manufactured from 304 or 316 stainless steel, in compliance with Plumberstar’s OEM stainless steel standards.

Key material composition requirements: Chromium (Cr) content ≥ 18% Nickel (Ni) content ≥ 8%

Corrosion Resistance Treatment

Specify whether additional corrosion protection is required based on the application environment, such as: Coastal or high-humidity areas, Chemical or industrial facilities. Optional treatments may include passivation or enhanced anti-corrosion coating, depending on usage conditions.

2. Production & Assembly Process — Technical Data

2.1 Core Process Flow & Control Points

The production process shall align with Plumberstar’s mature stainless steel manufacturing system. Key processes and control parameters include: Stainless steel sheet stamping, defining stamping pressure range and forming accuracy requirements, Filter punching processSpecify punch precision

Control hole alignment and consistency across the filter surface

Body–filter welding process

Welding method: e.g., mortise-and-tenon welding

Minimum weld height: ≥ 3 mm

Clearly define welding temperature and holding time

All critical control points must be identified and monitored to ensure process stability and repeatability.

2.2 Assembly & Installation Specifications

Component Assembly

Clearly define the assembly method between the filter basket and the drain body.

Specify whether the filter is designed to be detachable and washable for maintenance purposes.

Special Installation Requirements

If a height adjustment function is included, the Minimum adjustable range shall be ≥ 20 mm. Provide detailed assembly and adjustment instructions. Ensure full compatibility with Plumberstar’s production and assembly processes

3. Performance & Quality Inspection — Technical Data

3.1 Core Performance Test Standards

The following tests are mandatory for factory inspection: Drainage Flow Rate DN50 floor drain: ≥ 0.6 L/s Sealing Performance Pressure test at ≥ 0.2 MPa Zero leakage for 30 consecutive minutes Load-Bearing Capacity Grate load capacity: ≥ 10 kN/㎡

3.2 Durability & Environmental Testing

Durability Testing

Define product life-cycle testing requirements, such as:

Repeated filter removal and installation cycles

Long-term stepping and wear resistance tests

Environmental Adaptability Tests

For special environments, additional corrosion testing is required:

Salt spray resistance of ≥ 2000 hours with no visible corrosion

All durability and environmental test results shall be used as reference data for production quality calibration.

4. Compliance & Certification — Technical Information

4.1 Target Market Compliance Requirements

Technical specifications shall align with regional certification standards to allow proper production adjustment:

EU Market, EN 1253-1 (Drainage systems), EN 13618 (Corrosion resistance requirements), China Domestic Market GB/T 27710-2020 Floor Drain National Standard

All certification-related technical parameters must be confirmed in advance to ensure full regulatory compliance.