Description

|

Straight joint with chrome

It’s a chrome-plated straight joint, which is the core fitting for connecting two sections of pipes of the same specification in a pipeline system. It is suitable for water, gas, and other conventional media. Its core use is to extend the pipeline or repair a broken one, allowing the fluid to pass smoothly and adapt to the indoor humid environment for a long time. The use of thread or sleeve connections enables installation without complex tools, and manual tightening can be completed.

|

|

|

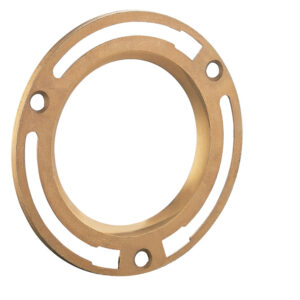

Brass Adapter Copper Fitting It’s a brass material copper adapter fitting, is a special adapter fitting for connecting different specifications and different types of interface pipes in the pipeline system, the purpose is to solve the interface mismatch problem in the pipeline connection, such as connecting the threaded interface with the welded interface, copper pipes of different diameters or other metal pipes accurately, realizing smooth connection of the pipeline, compact structure, small size, suitable for various specifications of pipeline interface conversion requirements.

|

|

|

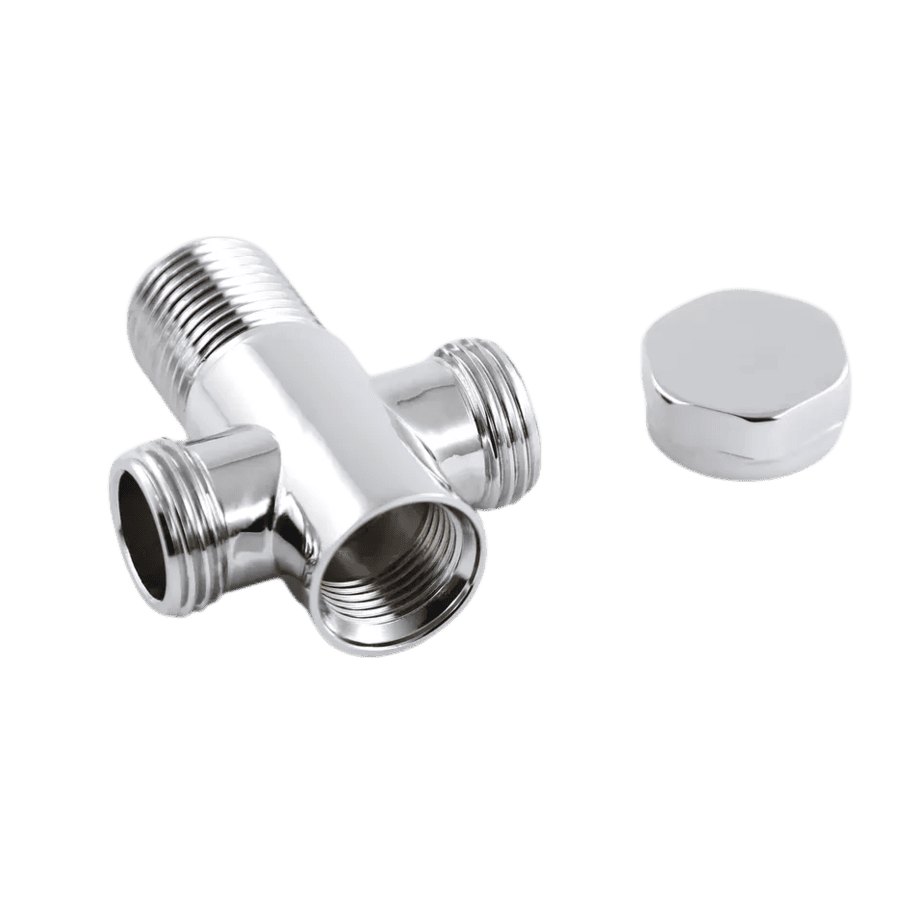

Brass sink drain fittings with plug

It is a set of brass basin drainage accessories featuring a sealing plug. It is the core drainage supporting component of the kitchen and toilet basin. Its core use is to realize the switching between drainage and water storage functions of the basin. The entire set of accessories typically includes the drainage main body, filter screen, sealing plug (either push-type or pull-type), sealing ring, and other components. The sealing plug allows for manual control of the drain outlet’s opening and closing. When water storage is needed, the plug can be closed. When drainage is opened, the filter screen can filter hair. Food residues and other impurities should be prevented from clogging drainage pipes.

|

|

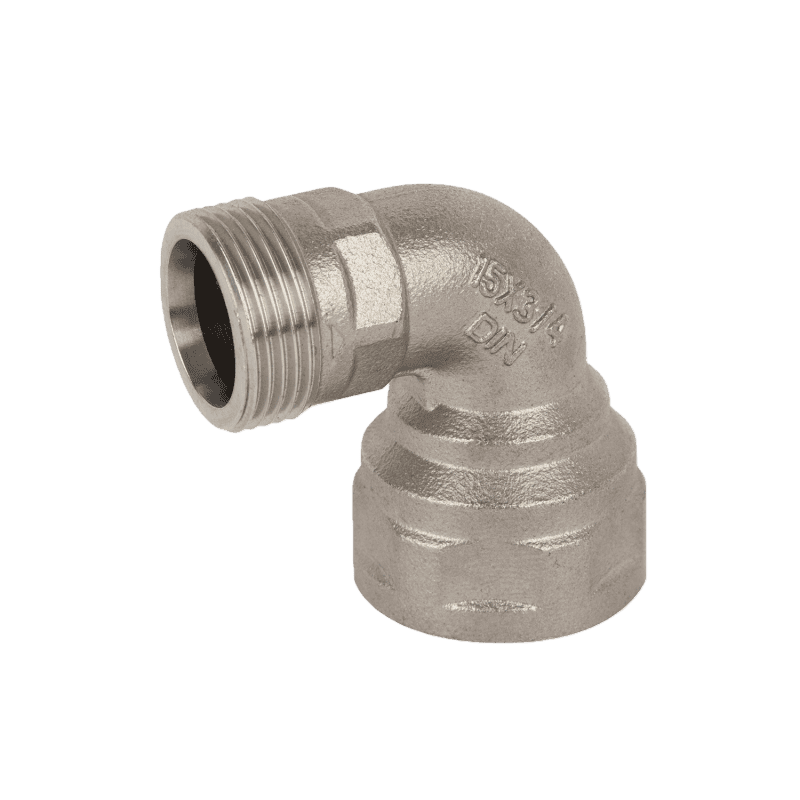

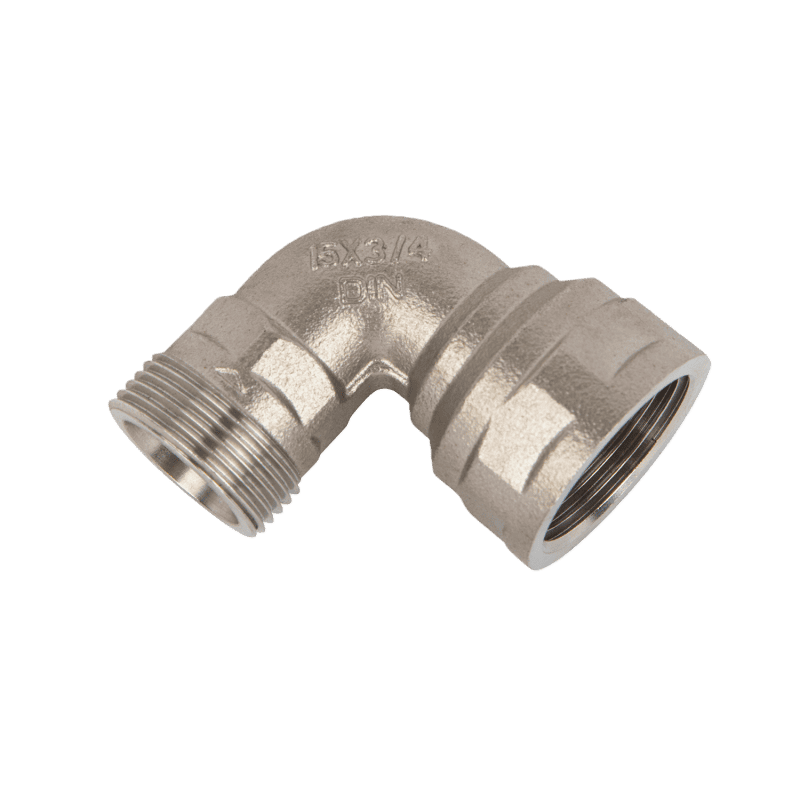

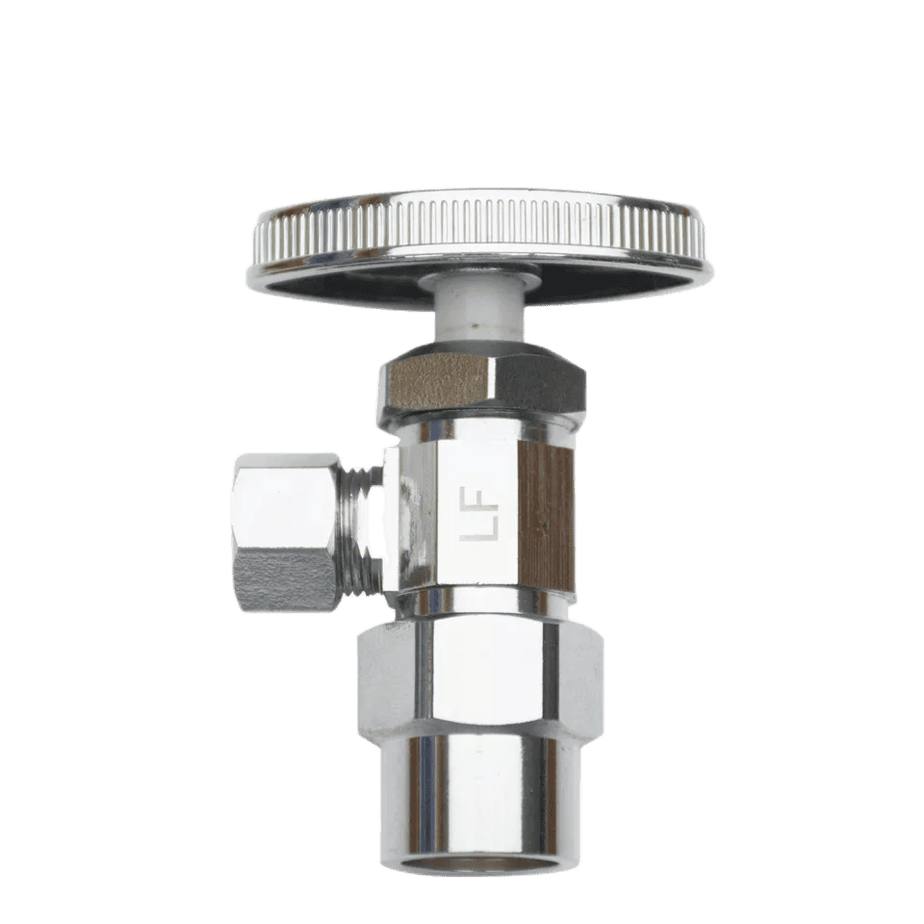

Water Stop Angle Valve

It’s a 90-degree angle valve with a water stop function, which connects the water supply pipe and the terminal sanitary ware in the pipeline system. (such as faucet, toilet, water heater) special control accessories, its core use is to accurately control the terminal equipment water inlet on and off, both water flow regulation and emergency water stop function, 90 degrees angle structure to adapt to the wall water pipe and sanitary ware inlet installation angle, save installation space, by rotating the handwheel can quickly open, close the water source or fine adjust the water flow size.

|

|

|

Brass Valve with Bent Nose It’s a brass curved nozzle valve, which is widely used as a garden valve in irrigation systems such as residential yards, nurseries, greenhouses, and farms. The purpose is to accurately control the flow of water. The unique curved nozzle design is its distinctive feature. It can not only adapt to horizontal pipeline connections, but also easily extend into small spaces. At the same time, it can avoid the bending of the connected hose. With a manual multi-turn or oval handle, it can be easily operated even with gloves.

|

|

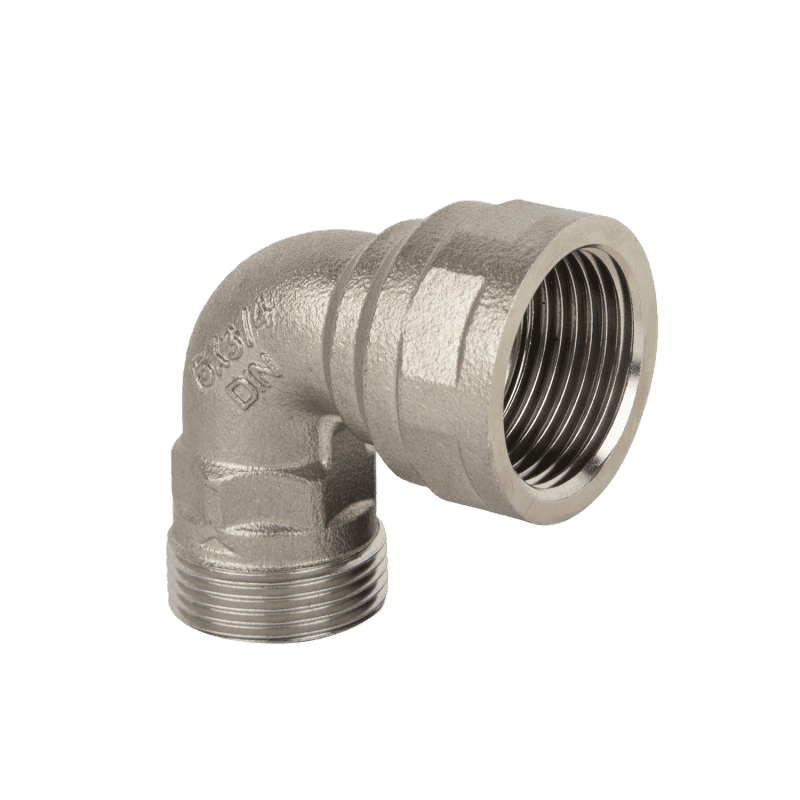

Brass Multi-Turn Angle Stop Valve It’s a brass 90 ° angle valve with multi-turn operation. It is a precision control fitting for connecting the water supply pipe and terminal sanitary ware/equipment in the pipeline system. The 90 ° angle structure adapts to the installation angle of the wall water pipe and sanitary ware/equipment, saving installation space. Operated by a multi-turn handwheel (usually requiring 3-5 turns to achieve full open/full close), it is easier to achieve fine flow regulation compared to an ordinary ball valve, making it suitable for scenes with precise flow requirements.

|