Description

|

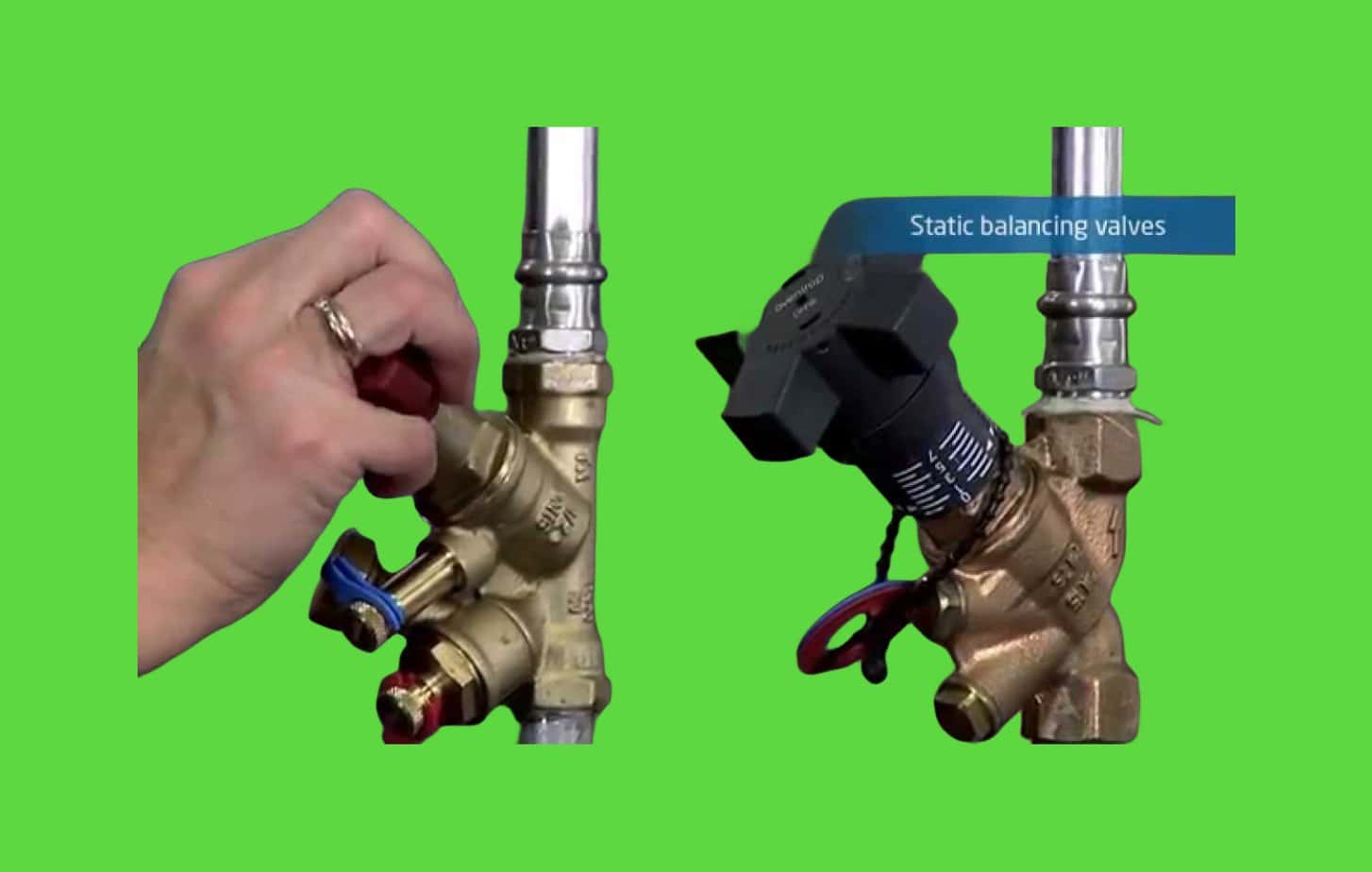

Static Digital Lock Balance Valve

The static digital lock balance valve is a special control valve made to keep hydraulic systems balanced. It has a built-in digital lock and is designed to maintain a stable hydraulic condition. This valve is made with a direct flow body, which improves the path of water inside and gives the valve smooth, equal-percentage flow.

|

|

|

Inspector Test And Drain Valve

This is a special valve that combines a two-lever ball valve, an observation window, and a stop valve in one unit. It is often used in pipelines for checking and maintenance. It can test whether a water flow alarm works properly and can also drain water from the main pipe. It can handle sewage, relieve pressure, and perform other extra functions.

|

|

|

Water Pressure Reducing Valve With Gauge

PRV is a device used to control and reduce water flow or pressure in a system. Its main job is to lower pressure that is too high, which makes the system safer and easier to operate and manage. PRVs help protect pipes and equipment from damage caused by excessive pressure. PRV devices of this type are commonly found in practical applications in piping systems, HVAC, and various types of fluid conveying and control equipment associated with industrial processes.

|

|

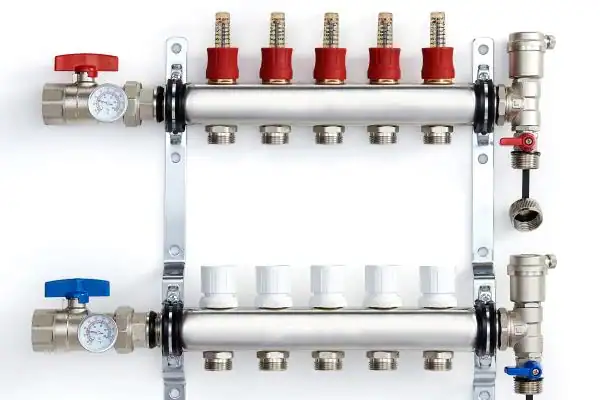

Visual Flowmeter Balancing Valve

The balance valve has a clear sight glass or flow indicator, so you can see the water or fluid flow and check the flow in real time. It can also stop the flow, adjust it, and keep the system balanced. This valve is mainly used in heating and cooling systems, water supply and drainage, industrial fluid transport, and similar systems. The flow in each pipe can be adjusted to match the needs of each branch or device, making sure the whole system works properly and evenly.

|

|

|

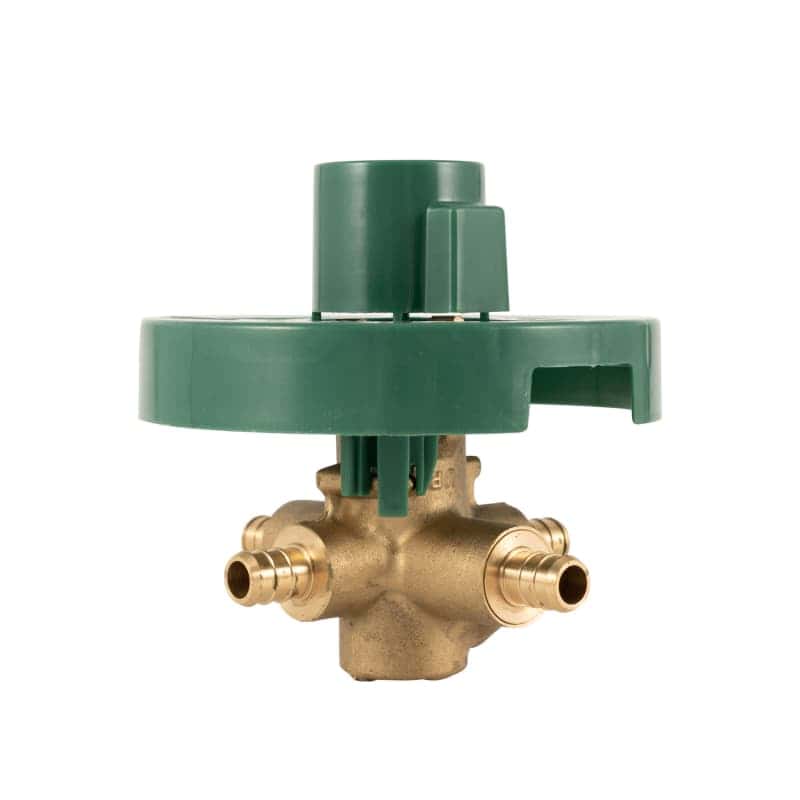

Manual Brass Balancing Valve

A Manual Brass Balancing Valve is a valve used in industrial systems to control flow and pressure by hand, usually by adjusting the valve disc. Its main job is to balance the flow and pressure in each branch of the system. Manually adjusting the valve opening accurately, so as to avoid abnormal operation of the equipment caused by excessive or too small local flow.

|

|

Boiler Safety Valve

A boiler safety valve is a safety protection device installed on boiler equipment. It has automatic pressure sensing and rapid pressure relief functions. The internal steam pressure exceeds the preset safety value due to abnormal combustion, improper operation, or system failure during boiler operation. The valve will automatically open and quickly release excess steam. It automatically closes after reducing the pressure in the boiler to a safe range.

|