FAQs of Multi Turn Brass Hose Bibb

1. Is the multi-turn brass hose bibb hot forged or cast?

Plumberstar multi-turn brass hose bibs are made with one-piece hot forging technology. The core valve body and all key stress-bearing parts are hot-forged brass—we don’t use casting at all.

Hot forging shapes brass raw materials under high temperatures. It makes the metal’s internal structure denser and the grains uniform. This completely avoids common casting defects like sand holes, air holes, and shrinkage porosity. It also boosts the valve body’s pressure and impact resistance a lot. The nozzles handle outdoor temperature changes and water pressure fluctuations easily, and won’t leak or crack after long use.

After hot forging, we use high-precision CNC machining for all key precision parts of the multi-turn water nozzle. This includes the valve stem matching area and the interface sealing area. The process keeps dimensional tolerances small and parts fitted tightly. So the multi-turn opening and closing feel smooth, and the sealing stays stable. Even with long-term, frequent use, the nozzle won’t loosen or leak water easily.

2. Does the multi-turn brass hose bibb meet US low-lead standards?

Yes, Plumberstar’s multi-turn brass hose bib strictly meets North American lead-free regulatory requirements.

- Plumberstar has a dedicated lead-free production line. The valve bodies are made of CW617N lead-free brass, with the weighted average lead content of all water-contacting wetted surfaces controlled at ≤0.25%. This meets the core limit requirements of U.S. lead-free regulations for pipeline fittings.

- In production management, processing equipment and production processes for lead-free brass are strictly separated from ordinary brass products. This eliminates any cross-contamination risks. Every batch of brass raw materials is tested for composition with a spectrometer when entering the factory, and a corresponding inspection report is issued. We’ve built a complete traceability system from finished valves back to raw material batches, making sure material compliance is clear and verifiable.

- For documentation and certification support, every order can include full compliance documents. This includes raw material composition inspection reports and relevant third-party certification certificates. What’s more, Plumberstar supports custom, lead-free, exclusive logos, English-compliant instructions, and lead-free certification labels. This meets the branding and compliance needs for North American market cross-border sales and project procurement.

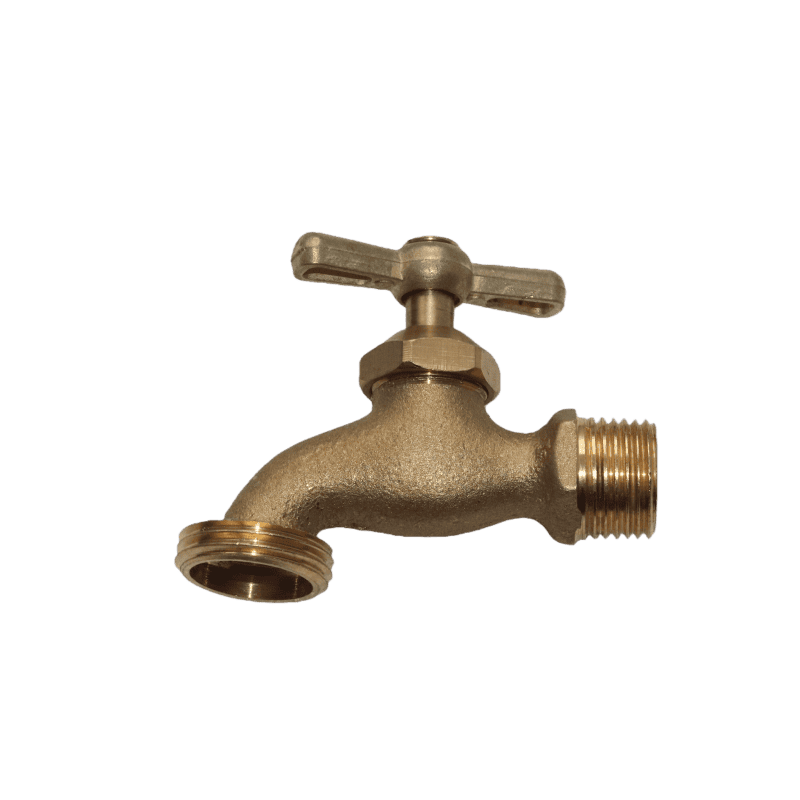

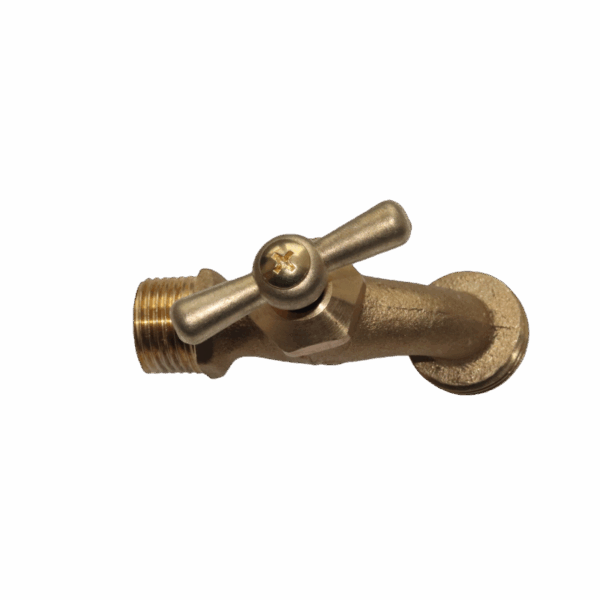

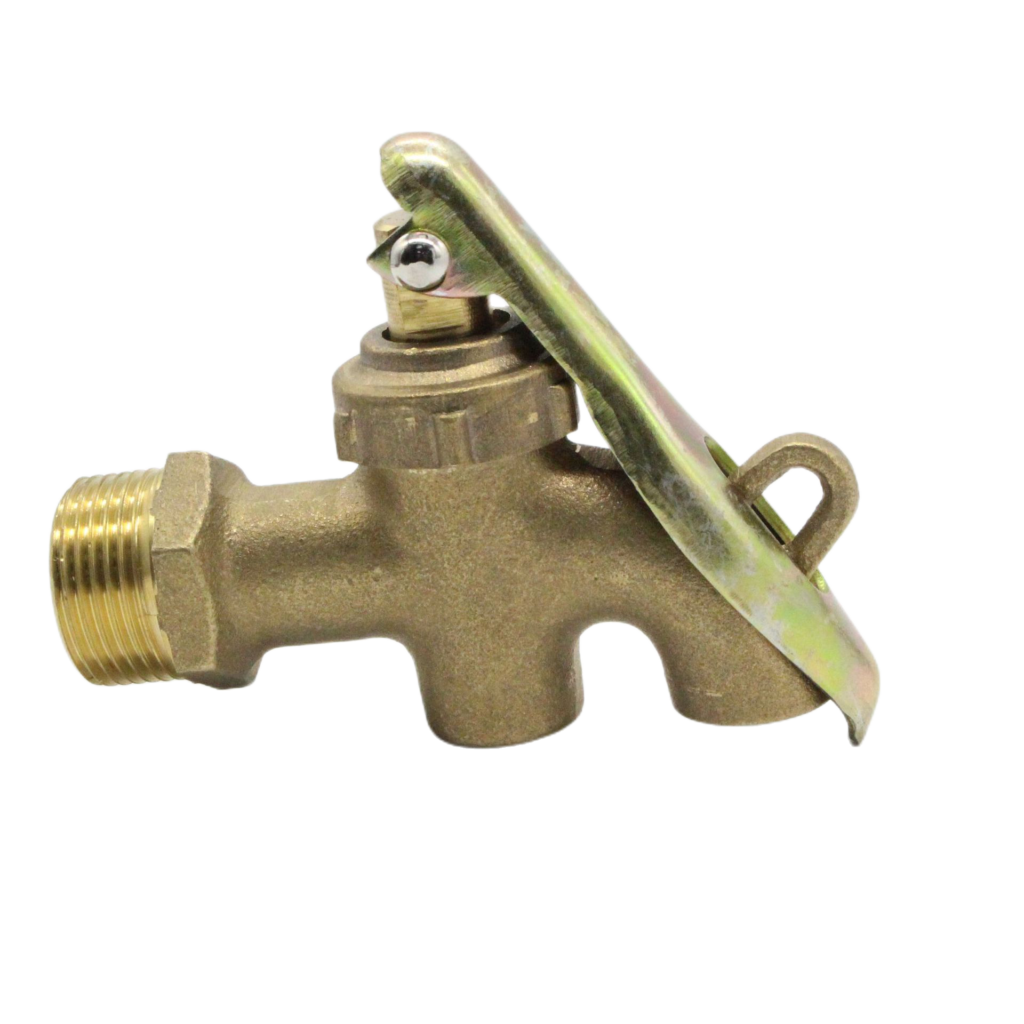

3. Can multi-turn brass hose bibb handle styles be customized?

Plumberstar is a professional custom valve factory. We support all kinds of handle customization to meet the needs of different markets and brand positioning.

- Material customization: Our standard handles are brass or iron. But we can replace them with aluminum alloy, zinc alloy, or stainless steel. These materials make the handles lighter and give them a more stylish, designed look.

- Surface treatment customization: Besides the regular natural color, we offer many surface treatment options. These include chrome plating, matte black, antique copper, and more. For example, matte black handles are great for markets that like modern-style designs.

- Appearance and structural design: We support custom handles in different styles. This includes ergonomic lever handles, retro cross models, or simple modern ones. You just need to send us your design sketches or ideas. Our engineers will create 3D models based on actual structural needs and send them to you for confirmation.

Once the plan is confirmed, we’ll develop the mold and make samples. When the samples are ready, we’ll send them to you for a physical check. Mass production only starts after you approve the samples. For large-volume orders, we can negotiate the mold development cost.

4. How to ensure consistency of multi-turn brass hose bibs?

Plumberstar has built a complete full-link management system. It covers four core areas: raw material control, process standardization, quality inspection, and process traceability. This stops risks in installation, use, and after-sales service caused by product differences.

- For raw materials, all valve bodies use specified-grade lead-free brass. All products in the same batch use brass from the same heat number. When raw materials enter the factory, they must pass two tests: spectral composition analysis and hardness testing. This eliminates product deviations from raw material differences right from the start.

- All products are processed with CNC equipment. Once the processing program is confirmed, the equipment controls key dimensions, surface finish,h, and wall thickness accurately—whether it’s the first piece or mass production. This avoids human errors. Every process has a clear Standard Operating Procedure (SOP), keeping the production process stable and controllable.

- We fully implement the “three-inspection system” for quality control, covering the whole production process:

- During production, we do patrol inspections on key dimensions and thread precision.

- At the semi-finished product stage, we sample-test component matching accuracy.

- At the finished product stage, we do a 100% full inspection. This includes water pressure seal testing, multi-turn opening/closing smoothness testing, and appearance inspection. Our quality inspectors also sample-test dimensional tolerance and valve body weight for bulk products. All inspection data is recorded uniformly, ensuring all indicators of finished products in the same batch are stable and consistent.

Each batch of products gets a unique batch number. It’s linked to the raw material batch used, production date, operators, and complete quality inspection records. This enables full-process traceability—from raw materials to factory delivery.

5. What’s the warranty policy for the multi-turn brass hose bibb?

Plumberstar provides a 3-year warranty on all multi-turn brass hose bibs.

Warranty Scope: This warranty only covers defects in the product’s materials and manufacturing processes.

After-Sales Process: If a problem comes up during the warranty period, just send us relevant proof—like product photos, videos, or inspection reports. Once our after-sales team verifies and confirms the issue, we’ll prioritize sending replacement parts or working out a solution for you.

If there’s a batch quality issue, we promise to send our engineering team to follow up immediately to analyze the root cause of the problem. Our engineering and technical staff to address it within 72 hours. They’ll find the root cause, make a remediation plan, and we’ll provide corresponding compensation on your next orders.

6. How are multi-turn brass hose bibs protected during transportation?

Each multi-turn brass hose bib is sealed and packaged individually. First, we wrap the product in a custom transparent PE protective film. Then we put it into a custom EVA foam or pearl cotton liner. This stops problems like thread deformation and loose switches caused by shaking or bumping during transport.

After individual protection is complete, we pack the products into custom-colored boxes or white boxes. We add extra paper partitions or foam slots inside the boxes. These keep the products fixed and separated in the same box, preventing them from shaking due to gaps. We uniformly seal all box openings with tape.

For full-box shipments, we use thickened five-layer corrugated outer boxes. The inside of the outer box is filled with buffer cotton to completely fill all gaps. This prevents the products from shifting or hitting each other during transport. The box is reinforced with cross-shaped strapping tape, and we add corner protectors to all four corners. This effectively stops edge and corner damage from squeezing during handling and stacking.

All our packaging solutions have passed drop and extrusion tests. They meet the protection needs for export logistics and transportation. This ensures the multi-turn brass hose bibs you receive have no appearance scratches, no structural deformation, and all accessories are complete and intact.

7. Can we visit the multi-turn brass hose bibb production line?

We sincerely welcome you to visit Plumberstar’s factory in person.

When you arrive, we’ll arrange for special business and technical staff to accompany you throughout. They’ll show you every key part of our production line in detail—brass raw material inspection, hot forging, CNC precision machining, surface treatment, finished product assembly, and full quality inspection. You can see the product’s production process, quality control standards, and how testing equipment works right on site. You can also have in-depth talks with us about technology, production, and quality-related issues.

If you need, we can also arrange on-site sampling inspections of work-in-progress or finished products. This helps you confirm product quality and consistency more directly.

If you can’t come for an on-site visit for now, we also offer online cloud visits. We’ll use high-definition real-time video to show you our production line and key processes fully. This way, you can clearly understand our production capacity and quality management system, even from far away.