Description

|

Straight-Through Female Joint

The straight-through female thread joint has female threads on one or both ends. Inside, the pipe path is straight, so the pipes connect without turning. It is a basic pipe connector used in factories and homes. It is used to make pipes longer, connect pipes to equipment, join branch pipes, and quickly connect or replace pipes during repair work.

|

|

|

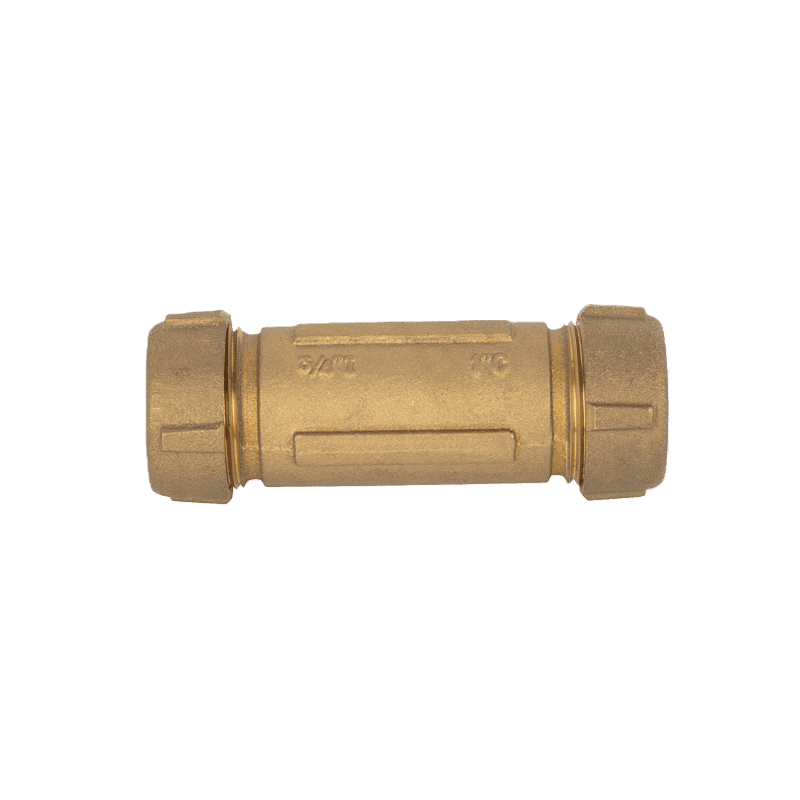

Water Meter Coupling

The water meter connector is a special part used to connect a water meter and pipes. It uses threads or a compression connection. It fits different water meter sizes and pipe sizes. Its job is to connect the water meter to the inlet and outlet pipes and keep the connection sealed. At the same time, it is easy to install and remove, which makes future checking, repair, or replacement of the water meter simple.

|

|

|

Brass Sleeve Coupler

The brass sleeve coupling has a hollow sleeve as the main body. It connects two straight shafts using a key, set screw, or tight fit. It is used in machines, fluid equipment, meters, water supply and drainage systems, and industrial machines. Its job is to send power between shafts, help fix small alignment errors, and keep the equipment running straight and stable.

|

|

Lead-Free Push-Fit Coupling

Lead-Free Push-Fit Couplings are used where water safety is very important, such as home drinking water systems, bathrooms, and water purifiers. They use a quick-plug design. You just push the pipe into the joint, and the inside claws and seals hold it tight by themselves. They work with PE, PPR, and copper pipes. People often use them for home pipe repairs, small upgrades, temporary water lines, and fast emergency fixes.

|

|

|

Push Fit Male Coupling

Lead-Free Push-Fit Couplings are used where water safety is very important, such as home drinking water systems, bathrooms, and water purifiers. They use a quick-plug design. You just push the pipe into the joint, and the inside claws and seals hold it tight by themselves. They work with PE, PPR, and copper pipes. People often use them for home pipe repairs, small upgrades, temporary water lines, and fast emergency fixes.

|

|

Push-In 90 Degree Elbow Coupling

The core of the Push-In 90 Degree Elbow Coupling is a quick-connect structure. It does not require welding, hot melting, or additional tools. Simply insert the pipes of the corresponding specifications into the ports at both ends of the joint, and the internal claws and sealing rings will automatically lock and seal. It can realize a 90-degree turn connection of the pipeline. Some models are equipped with a disassembly ring, and the pipeline can be separated by lightly pressing.

|