FAQs of Hydraulic Balance Manifold

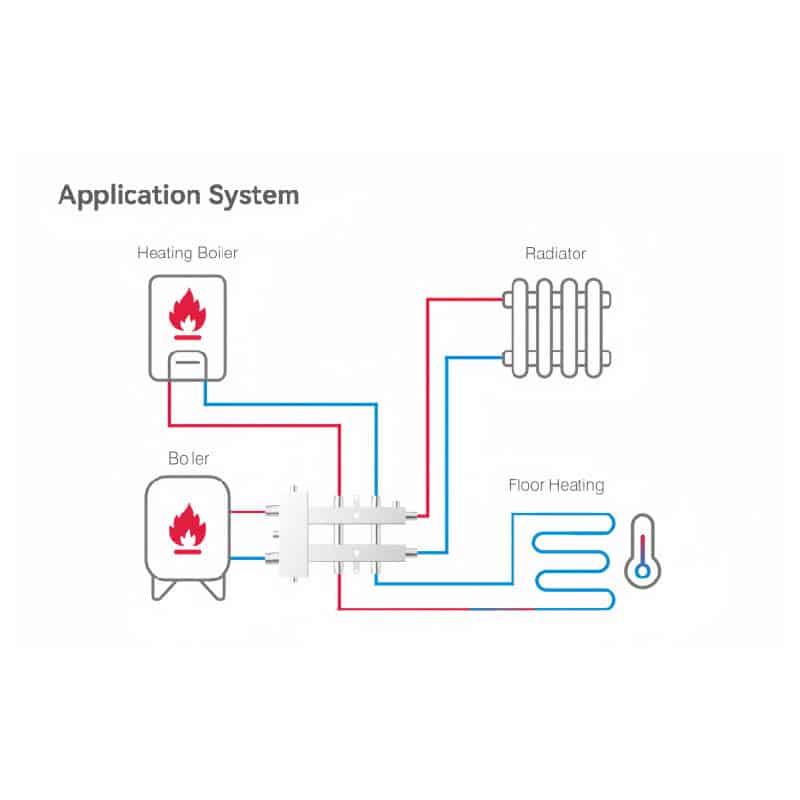

1. What’s the difference between a hydraulic balance manifold and a simple distribution tee system?

A hydraulic balance manifold is designed to control flow and pressure.

By separating primary and secondary circuits, it helps keep flow deviation typically within ±5%, improving system stability and reducing hydraulic interference between zones and pumps.

A simple distribution tee system only splits the flow.

In multi-zone systems, flow deviation between circuits can easily reach 20–30%, which often leads to uneven heating, repeated balancing, and longer commissioning time.

2. Can test reports be provided for each hydraulic balance manifold order?

Plumberstar provides a complete and fully traceable batch inspection report for every batch of hydraulic balancing manifolds.

Core Inspection Items

The inspection report covers multiple key quality indicators, including:

- Material composition analysis, such as lead-free content testing of brass valve bodies;

- Pressure resistance and pressure-holding tests were conducted at 1.5 times the rated pressure, with a holding time of at least 30 minutes.

- Hydraulic balancing performance tests to ensure that the flow deviation of each branch is controlled within ±5%.

In addition, the report clearly indicates the batch number, production date, and applicable standards, ensuring complete and transparent information.

Report Delivery

For each batch of the hydraulic balance manifold, the inspection report is supplied in hard copy together with the shipment. An electronic version is also provided for archiving, facilitating project acceptance, customs clearance, and relevant regulatory filings.

3. Is a 3-party inspection available for hydraulic balance manifold orders?

As a professional valve manufacturer, Plumberstar fully supports third-party inspection services for orders, with the following implementation arrangements:

Selection of Inspection Bodies

Customers may appoint their own recognized third-party inspection agencies, including internationally accredited organizations such as SGS, BV, and Intertek.

Inspection Standards

Inspection items and standards can be carried out in accordance with customer requirements or in accordance with applicable international standards and industry specifications.

Inspection Coordination and Process Support

Once a third-party inspection request is confirmed, we will reserve inspection samples in advance. We also coordinate factory production schedules with the inspection timeline.

We assign dedicated personnel during on-site sampling and testing. They will fully cooperate with the inspectors.

We will provide complete product technical documentation. These include drawings, material certificates, and production records. This ensures the inspection process runs efficiently and in order.

4. Is OEM branding supported for hydraulic balance manifolds?

Plumberstar offers OEM brand customization services for hydraulic balance manifolds. By partnering with Plumberstar, you will receive the following core support:

Comprehensive Brand Customization

- Valve bodies can be laser-engraved or custom-molded to incorporate your brand logo, model numbers, and other identifiers.

- Handle colors and shapes, as well as flow meter scale dials, can be customized to align with your brand’s VI system.

- Customized packaging with brand information is available, including color boxes, labels, and outer cartons, along with supporting documents such as installation manuals and technical data sheets.

Stable Product Quality

- Every manifold is subjected to 100% air-tightness and hydrostatic pressure testing before shipment.

- All raw materials undergo spectrometric composition analysis to ensure compliance with relevant international standards.

- Complete batch inspection reports can be provided upon request.

Technical and Engineering Support

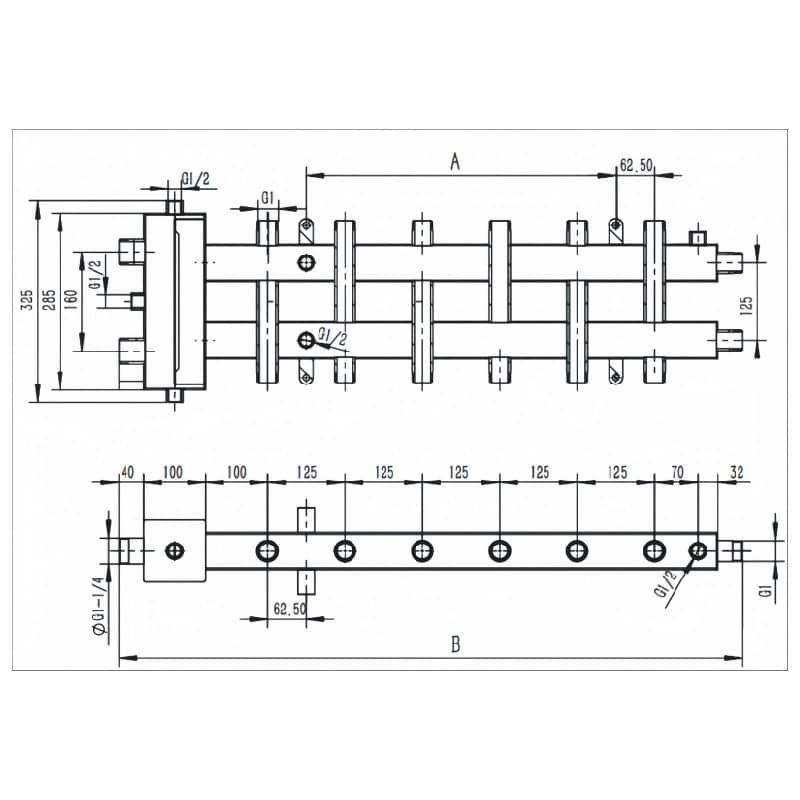

Our engineering team can support your project based on your design concepts or preliminary sketches, providing technical services from 3D modeling and structural optimization to sample prototyping.

More Competitive Profit Margins

- Direct factory sourcing eliminates intermediaries, resulting in lower procurement costs.

- Private-label products help enhance market pricing power and overall profit margins.

Plumberstar is a manufacturing partner with strong technical capabilities, strict quality control, and efficient responsiveness. We are dedicated to helping customers build and strengthen their brand advantages in highly competitive markets.

Contact us today to start your OEM brand customization partnership for manifolds.

5. Can you laser-engrave our logo onto the hydraulic balance manifold body?

We support customized laser engraving services.

Besides brand logos, we can also engrave other content as needed. Like product model numbers, serial numbers, key technical parameters (such as pressure ratings and connection sizes), and relevant certification marks (such as cUPC, WaterMark).

You just need to provide a high-resolution vector file of your brand logo. Formats like .AI, .EPS, or.DXF. Our engineers will create a mock-up of the laser engraving for you to review. You can confirm the engraving position and dimensions. Once approved, the finalized engraving plan will be used in mass production. This ensures consistency and full process control.

6. Can you provide a free sample for testing before I place a hydraulic balance manifold order?

At Plumberstar, we believe that letting customers test samples in person is essential for building a strong partnership.

We provide samples for free—customers only need to pay for international shipping. You can use a collect account with DHL, FedEx, UPS, or other courier services, or choose to prepay the shipping fee.

Once the sample model and specifications are confirmed, we will ship it as soon as possible. After you receive the samples, you can test installation, pressure resistance, and performance, then share your feedback with us. This helps us improve the product and move our cooperation forward.

7. Do you provide real-time tracking for shipped hydraulic balance manifold orders?

Plumberstar set up a fully transparent shipment tracking system. You can check your order status anytime. Our tracking process has three simple steps:

Your order will undergo 100% pressure testing and a final inspection. Once finished and passed, we’ll book the shipment right away. We’ll send you a Shipping Notice with the estimated departure (ETD) and arrival (ETA) dates.

You can track your shipment’s location, transit status, and updated ETA through the official system. Your dedicated project manager will also keep an eye on important milestones. Things like transshipments and arrival at the destination port. They’ll update you with key information in time.

Before your shipment reaches the destination port, we’ll send you an advance notice. We’ll also provide all necessary customs documents. Like a commercial invoice, a packing list, and a certificate of origin. These help your customs agent clear the cargo smoothly and on time.

8. Is air freight available for urgent hydraulic balance manifold orders?

Yes, for urgent orders, if you request air freight, we’ll contact our freight forwarding partners right away. We’ll provide you with a detailed quotation that includes both product costs and air freight charges. You can see all expenses clearly.

We’ll start expedited production while calculating the air freight cost. After you confirm the quotation, we’ll prioritize production, testing, and packaging. We’ll make sure the goods are delivered to the airport for dispatch as quickly as possible.