FAQs of Hydraulic Arrowhead Collector

1. Can a material traceability report be provided for the hydraulic arrowhead collector?

Plumberstar provides a complete material traceability report for every batch of hydraulic arrowhead collectors.

The report includes basic raw material information, such as batch numbers for lead-free brass, stainless steel, and sealing parts. It also shows supplier documents and material test results, for example, brass composition test reports.

Production records are included as well. These cover casting and machining batches, heat treatment settings, and assembly records, allowing each main production step to be traced.

After production, all products are tested for pressure resistance and sealing performance. The test results are recorded in the report to confirm that the products meet the required specifications.

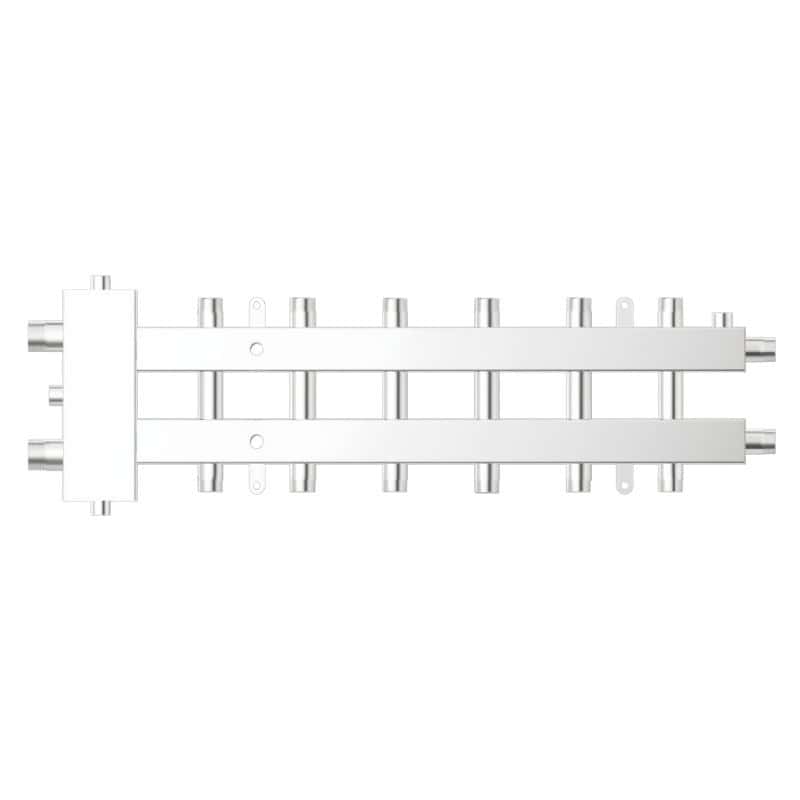

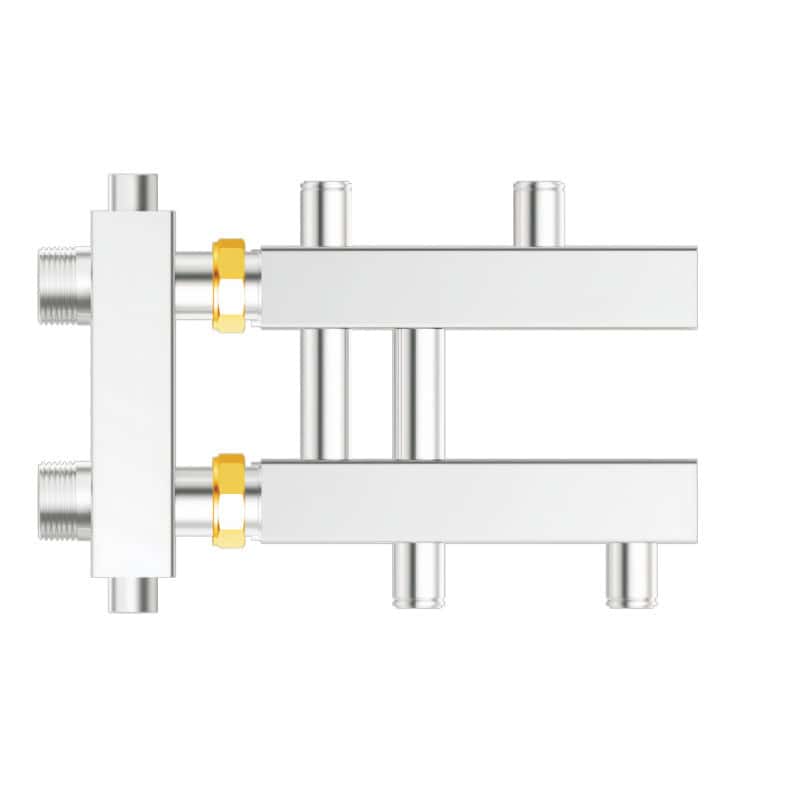

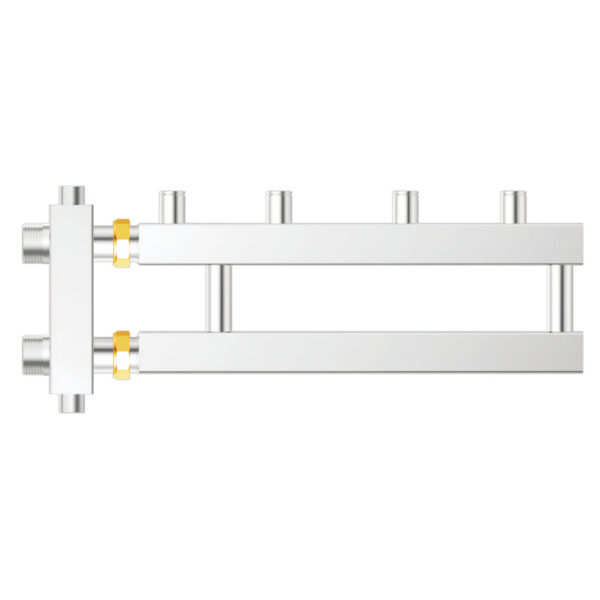

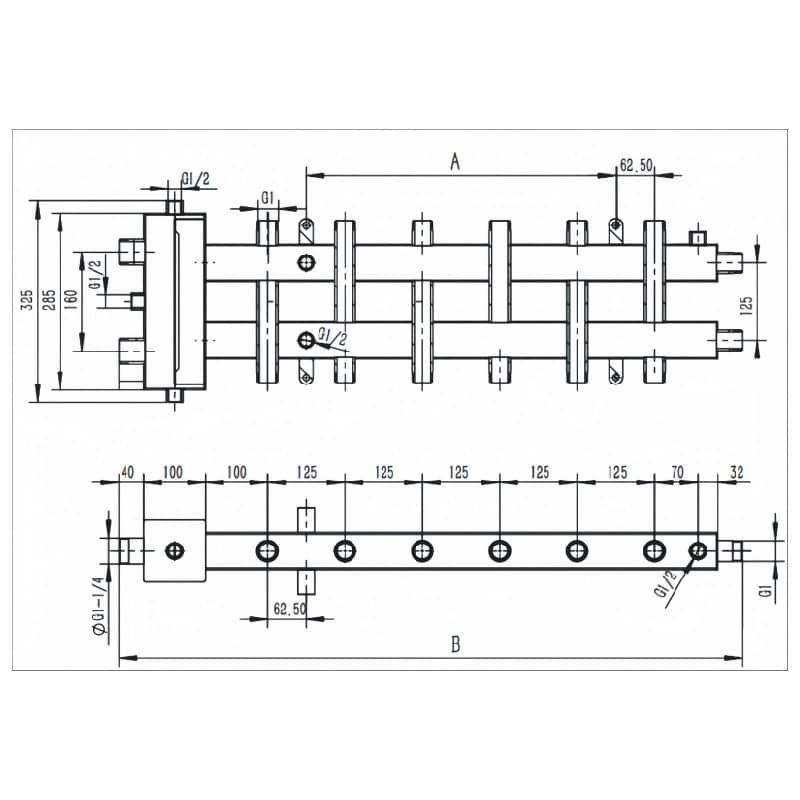

2. Can the outlet distance for the hydraulic arrowhead collector be customized?

Yes, you only need to provide a rough sketch, a technical drawing, or just specify the required center distance and number of outlets.

Our engineers will prepare 2D or 3D drawings based on this information. We’ll send the drawings to you for review. This makes sure both sides fully agree on the design details.

After you confirm the drawings, production will start at our CNC machining center. Our team will manufacture the products strictly according to the approved specifications.

3. What is the lead time for the ODM hydraulic arrowhead collector?

A new ODM hydraulic arrowhead collector project usually takes 8–12 weeks from concept confirmation to first shipment. The ODM process is divided into two main stages. The timing of each stage is as follows:

First Stage: Design, Mold Opening, and Sample Confirmation

- We will fully communicate with you about project requirements. We’ll confirm the target market, core pain points, cost range, and performance requirements.

- Our engineering team will turn your ideas into 3D models and 2D technical drawings. We’ll do structural and process evaluation as needed. Then we’ll make corresponding forging dies and machining fixtures, based on design complexity.

- Mold quality directly affects the consistency and stability of later batch products. This step can’t be expedited. We’ll use the new mold to make samples. Then complete pressure, flow, size accuracy, and material composition analysis tests.

- After testing, we’ll send the samples to you for actual inspection and testing. Once you confirm the samples, the project moves to the next stage.

Second Stage: Batch Production

After sample confirmation, the product enters formal batch production. This includes raw material procurement, forging, CNC machining, assembly, testing, and packaging.

The production cycle is similar to standard products. It depends on the order quantity and factory scheduling.

At project launch, Plumberstar will provide a detailed project timeline. It will define the estimated completion time of each key node. We’ll keep communicating with you throughout the process. Make sure you know the project progress in real time.

4. Do you offer tiered pricing for large-volume hydraulic arrowhead collector orders?

Plumberstar offers flexible, tiered pricing for large purchases. It’s designed to build a mutually beneficial partnership with you:

Standard Wholesale Price

- Applicable to: Regular orders that meet the minimum order quantity (MOQ).

- Price advantage: Get competitive factory-direct pricing.

Volume Discount Price

- Applicable to: Customers with single order volume far exceeding the normal standard. Or those who promise to meet the agreed purchase volume in a single quarter.

- Price advantage: Get more substantial discounts on top of the standard wholesale price.

Strategic Partner Price

Target: Strategic partners looking for long-term stable cooperation and signing annual purchase agreements.

Exclusive rights:

- Optimal pricing: Enjoy the best supply price in the entire cooperation system.

- Priority guarantee: Get priority in production scheduling and delivery.

- R&D cooperation: Have priority access to new product development projects.

5. How is the pressure test conducted before the hydraulic arrowhead collector ships?

We first plug all the connection ports of the hydraulic arrowhead collector. This ensures the test loop is fully sealed.

We inject clean water as the test medium. Evacuate all air in the loop to prevent air residue from affecting test accuracy. Connect a high-precision pressure sensor and a data recorder. They monitor pressure changes in real time. We pressurize the loop to 1.5 times the rated working pressure. For example, products with a rated pressure of 1.6MPa will be tested at 2.4MPa. The pressure holding time is no less than 30 minutes.

During the test, we check if the valve body has deformation, leakage, cracks, or other problems. The data recorder tracks the pressure curve throughout the process. It ensures there is no significant pressure drop.

After the test, we generate a batch test report. Unqualified products are sent for rework immediately. They will undergo 100% pressure testing again after rework. Only products that pass the test can be put into storage.

6. Can you arrange door-to-door ocean freight for the hydraulic arrowhead collector?

Sure, you just need to provide the final shipping address.

We’ll arrange suitable shipping dates and track the goods all the way. You can check their location anytime you want.

Our freight forwarders will handle import customs clearance procedures in your country. This includes customs duties, tax settlement, and all kinds of document preparation. After the goods are cleared, we’ll arrange trucks to deliver the containers or pallets from the port to your designated warehouse address.

7. What is your procedure for hydraulic arrowhead collectors damaged in transit?

If you find transportation damage when receiving the goods—like damaged outer packaging, deformed product appearance, or seal failure—we’ll get in touch with you within 24 hours. We’ll determine responsibility based on relevant info, such as cargo packaging and transportation route.

After verification, if the damage is caused by transportation, you don’t have to bear any extra costs. We’ll start the replenishment or return process right away. You can get the corresponding products reissued for free. Or you can deduct the corresponding amount from your next order.

If the received goods are quite different from your order, we’ll give you a solution within 72 hours. We’ll send engineers to the site to investigate and decide on the handling plan. We’ll do our best to ensure your project’s progress isn’t affected.

8. Can we visit the hydraulic arrowhead collector production line?

Plumberstar welcomes you to visit our hydraulic arrowhead collector production line.

We’ll provide professional and comprehensive visit services based on your needs. We’ll work out exclusive tour routes for you. And arrange professional technical instructors to accompany you the whole time.

For customers with cooperation intentions, you can also check out samples on site. And verify test reports in person. This lets you get a direct, intuitive understanding of our product quality.