FAQs of Boiler Safety Group

1. Can different connection methods be provided for the U.S. and European markets of Housing?

Yes. Plumberstar can provide different connection methods for the U.S. and European markets.

- For the European market: The connection threads of the Boiler Safety Group we customize are manufactured in accordance with BSP, ISO228, and DIN EN standards.

- For the U.S. market: We manufacture in accordance with local American thread standards such as IP and NH.

Different regions use different thread standards. Mixing them can cause serious compatibility issues. Please check the applicable thread connection type of the pipeline when confirming the order.

2. What are the advantages of using forging to manufacture Boiler Safety Group compared to casting?

In the manufacturing of boiler safety groups, forging has more advantages over casting in terms of performance and reliability. It is more suitable for high-pressure and high-temperature boiler system applications.

1. Higher structural density: Forging involves plastic deformation of metal billets through pressure. In contrast, defects such as pores, shrinkage cavities, and loose structures are prone to occurring during the casting process. The metal grains in forgings are refined and arranged in a streamline along the stress direction. Compared with castings of the same material, their tensile strength, yield strength, and impact toughness can be increased by 30%–50%.

2. More stable dimensional accuracy and less post-processing: Forging dies have higher precision. The formed parts have smaller dimensional tolerances and uniform wall thickness. Castings often require extensive machining to remove surface defects and correct dimensional deviations. Forging can avoid the structural weakening caused by excessive machining of castings.

3. Higher material utilization rate: Although the initial cost of forging dies is higher, the material utilization rate of forging can reach 70%–90%. And it is significantly higher than that of casting (40%–60%). For bulk orders of boiler safety components, the overall cost advantage of forging can be reflected.

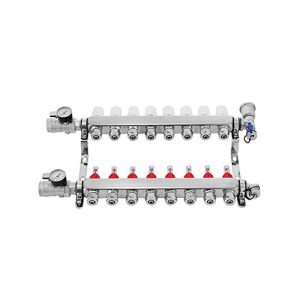

3. Can you pre-assemble the safety valve, pressure gauge, and air vent into the housing for me?

Yes, we can assemble the safety valve, pressure gauge, and exhaust valve into the boiler safety group housing.

1. Assembly process: We will pre-install all components in the factory workshop. This includes threaded connections, sealing ring installation, and torque calibration. After the assembly is completed, we will conduct comprehensive pressure tests and functional tests.

2. Support for customizable configurations: You can select the safety valve, pressure gauge, and exhaust valve in Plumberstar. And you can customize their connection sizes and pressure values. Alternatively, you can specify the brands of the safety valve, pressure gauge, and exhaust valve.

3. Convenient on-site installation: The pre-assembled boiler safety group will be delivered as an integrated unit. It comes with standardized flange or threaded interfaces, which can be directly connected to your boiler system. This saves on-site assembly time and improves construction efficiency.

The pre-assembly service for bulk orders (≥500 units) is free of charge; small batch orders may incur a small assembly fee.

4. Can I have my company’s logo engraved directly on the Boiler Safety Group?

Of course! We can directly engrave your company’s logo on the boiler safety groups.

1. Engraving methods and applicability: We can use laser engraving and precision stamping on the shell. The depth of laser engraving is 0.1–0.3 mm. It will not affect the structure and use of the product, nor will it fade or wear. Precision stamping can produce more three-dimensional logos, which are suitable for high-end customization.

2. Customization details: You can specify the position of the logo to be engraved on each part of the boiler safety components. Not only the company logo, but also the product model and batch number can be engraved.

3. Cost and minimum order quantity requirements: For bulk orders (≥500 units), logo engraving is free. For small batch orders (<500 units), a symbolic plate-making fee will be charged. If you place additional orders later, this fee can be waived.

5. Do you charge for the 3D design services of the Boiler Safety Group?

The 3D design services we provide for the boiler safety group are free of charge for formal bulk orders. There are clear terms for different cooperation scenarios:

Free design for bulk orders. If you place a formal bulk order (≥500 units) for the boiler safety group, we will provide a full set of 3D design services free of charge. This includes 3D modeling of shell components, matching of internal components, simulation of logo engraving positions, and dimension verification. We will revise the design draft multiple times to meet your requirements and ensure the 3D model meets your actual application needs.

Only a nominal fee is charged for small-batch prototype design. For small-batch orders (<500 units) or orders without subsequent formal orders, we will charge a nominal design fee. Depending on the customization’s complexity, it is generally between 200 and 500 US dollars. If you place a formal bulk order within 3 months after receiving the design draft, this fee can be deducted from the product cost.

When delivering the design results, we will provide 3D files in a common format and 2D engineering drawings with detailed dimensions. These files can be directly used in your project verification and installation simulation.

6. Can you consolidate my order of housing with other products to save on shipping?

Yes, we support combining orders for boiler safety component enclosures with other products.

We will classify and stack all goods by size, weight, and fragility. This allows for maximum utilization of container space. Our warehouse team will use a unified standard packaging for combined orders. Heavy products will be placed at the bottom. For precision components (such as pressure gauges and safety valves), they will be packed into shockproof boxes and secured on top to prevent damage from collisions during transportation. We will also mark your brand information and part numbers on each package. Combining multiple products into one shipment can save the costs of separate bookings and multiple origin handling fees. We will choose the most cost-effective container size. This can reduce shipping costs by 20%–40% compared to shipping separately.

7. What are the benefits for wholesalers of choosing direct sales from Boiler Safety Group manufacturers?

Wholesalers who choose direct sales from Boiler Safety Group manufacturers can gain competitive advantages in terms of cost, service, etc.

1. Reduce costs and increase profits: Direct sales from manufacturers bypass agents, distributors, etc. Wholesalers can obtain goods at prices closer to the production cost. For the same purchase quantity, the procurement cost can be 15%-35% lower than through intermediaries. At the same time, our factory will set up tiered discounts for wholesale orders. The larger the purchase quantity, the lower the unit price. There are no distribution fees, which can directly increase wholesalers’ profits. It will also be more flexible in terminal pricing.

2. Stable supply and strong controllability of delivery time: Direct sales from manufacturers can ensure the stability of the supply source. There will be no out-of-stock situations caused by insufficient inventory or intermediary allocation problems. For bulk orders, manufacturers can coordinate production schedules directly. Adjust the delivery time to match the wholesalers’ sales rhythm. It can also provide free short-term warehousing services (storage for 7 working days) to avoid additional storage fees when goods arrive at the port in advance.

3. More efficient after-sales support: Wholesalers can directly obtain professional technical support from manufacturers. There is no need to relay through intermediaries, and the response is more timely. For after-sales problems of bulk orders, manufacturers can provide unified return, exchange, and maintenance services. This greatly reduces wholesalers’ after-sales operational costs.