Boilers are high-pressure and temperature systems. It produces vapor to drive vapor turbines for power generation. If due to some cause of process or fault in apparatus or controls. Yet, the pressure in the design goes more than the specified limit of the matter of structure. And it can cause disaster. Safety valves are provided in the boiler at many sites to avoid such disasters.

The safety valve is a steam system’s most effective safety device. Safety valves offer safety for plant workers and equipment from over-pressure situations. The chief purpose of a safety valve is to release pressure. Its site is on the boiler steam cylinder. It will be exposed when the pressure of the entrance side of the regulator rises past the fixed pressure.

What is a Boiler Safety Valve?

A boiler safety valve is a pressure release system installed in boilers to ensure that the pressure within the system does not exceed a pre-defined limit. If the pressure surpasses this threshold, the safety valve opens, releasing excess pressure and preventing boiler explosions or malfunctions.

Yet dependent on the powerful flow capability of the boiler. The actual ability of the protection valve at the installation point. It must go beyond the steam regulator valves if the steam regulator flops to open. In many circumstances, two protection controllers per boiler are essential.

How does the Boiler Safety Valve Work?

The safety valve has three central portions: outlet, disc, and coil. Pressurized steam goes into the regulator. Yet, further through the nozzle and then threads into the boiler. The disc is the lid to the nozzle, which unlocks or closes depending on the pressure from the boiler. The spring is the pressure controller.

As a boiler starts to overpressure, the nozzle will get an elevated pressure. Although from the inlet sideways of the regulator. It will begin to noise like it is bubbling when the pressure grows higher than the prearranged pressure of the spring. Then, the disc will start to rise and liberate the steam. It creates a “pop” noise after it is released. Yet, the condensation and pressure drip lower the set pressure of the regulator. The spring will close the disc once the safety regulator has popped. Check the valve to ensure it is not cracked and is operating.

Why Do We Need Safety Valves in Boilers?

A safety valve is usually stated as the last link of the protection cover. The boiler can surpass its extreme permissible working pressure-free safety valves—and not only harm equipment. But also harm or destroy plant operatives that are nearby. Many varying can be reasons for a safety valve on a boiler to boost. Such as a compressed air or electricity disaster to regulate arrangement. Or an imbalance of feed water amount. Yet, it is caused by a closed or open separation valve.

Boiler explosions have been answerable for extensive loss to companies during the ages. Today’s boilers furnish safety valves. Boiler safety valves aim to avoid extra pressure. It is liable for those destructive bursts. This protects the boiler in contrast to the extremely high pressure of the vapor drum. Positions of a safety valve in the Boiler: Safety valves are situated on the top of the boiler.

A safety valve is considered to be opening. And relieve extra pressure from the boiler. Yet, by discharging a volume of fluid from within the equipment. When prearranged, additional stress got. Suppose the working pressure in the system goes overhead. Then, the secure boundary of the material of the structure can cause a damaging disaster.

When a safety valve has elevated, it is vital to do a complete boiler checkup. And approve that there are no other boiler-checking matters. A safety valve must only work once; protection valves would not lift nonstop. Having the safety valves washed and reapproved with a National Board valve repair (VR) stamp is significant. And need by a native program or authority. Safety valves are a serious constituent in a steam scheme.

The function of a Boiler Safety Valve

It preserves the Boiler pressure inside the Employed force. The safety Valve does not permit the steam pressure to rise overhead the safe boundary. Suppose the steam pressure in the boiler cylinder goes beyond the employed pressure. The safety valve unlocks and allows the steam to discharge into the environment. The valve ends again when the pressure achieves the functioning pressure.

Principle of Boiler Safety Valve

The valve is pushed in contradiction to a seat through some external power. The strength of boiler steam below the valve is more significant than the exterior force. The controller is raised off its seat, permitting the moisture to discharge—the valve seats on the seat once when the steam pressure is resistant to working pressure over again. Thus, the safety valve performs as a pressure relief valve. It liberated more steam from the boiler.

In some countries, stuff relating to the fittingness of this valve for steam boilers is EN 12953. Many altered forms of safety valves fix steam boiler plants. But usually, they necessity all meet the following criteria:

The total release capability of the safety valves must be equal to the boiler’s ‘from and at 100 °C’ capability. If the ‘from and at’ evaporation is used to size the safety valve. The protection valve capability will elevate more than the powerful evaporative boiler capability.

The safety valve’s whole value release. Whose competency must be achieved within 110% of the boiler design pressure? The tiniest inlet bore of a protection valve linked to a boiler will be 20 mm. The usual extreme pressure of the protection valve will be the boiler system. There must be a suitable border between the normal working pressure of the boiler. And the installation pressure of the protection valve.

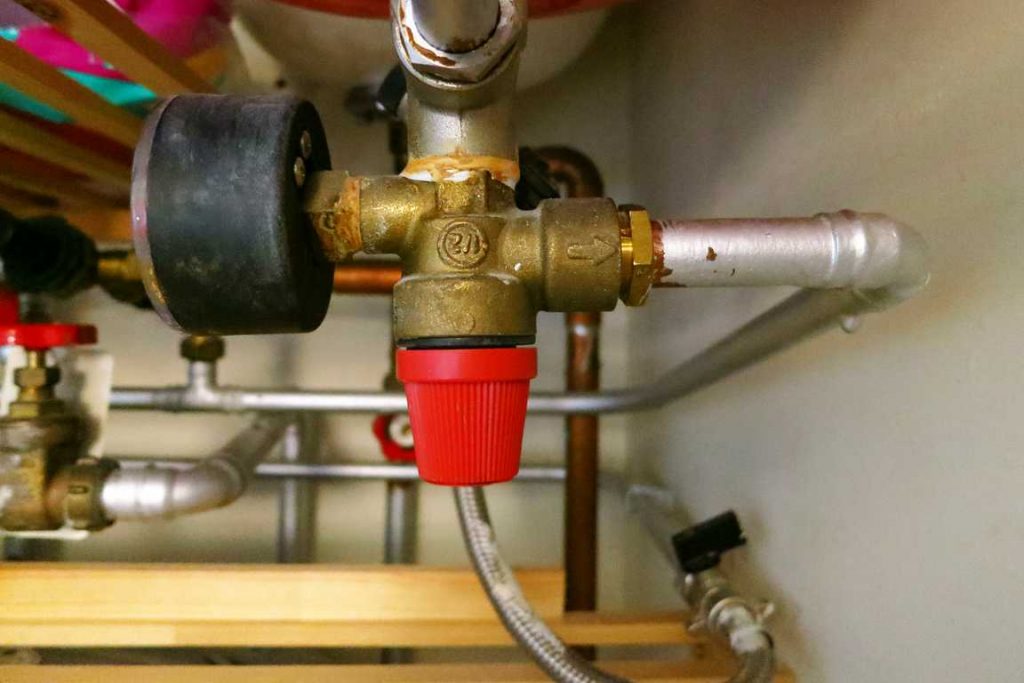

Brass safety valve

Types of Safety Valves:

- Spring-loaded safety valve

- Pilot-operated Pressure-relief Valve

- Dead weight safety valve

Spring-loaded pressure-relief Valves

Usually, the safety valve is a Spring-loaded pressure-relief valve. The spring weight planned to push the “Disc” in contradiction to the inlet pressure. It depends on the watery kind, such as steam, gas, or liquid. We contribute a Bellows model to flawless the back pressure result.

Dimension Chart

| Normal Size | H~ | ∅B |

| 15mm | 190 | ½ inch BSP |

| 20mm | 222 | ¾ inch BSP |

| 25mm | 225 | 1 inch BSP |

| 40mm | 262 | 1.1/2 inch BSP |

| 50mm | 345 | 2 inch BSP |

Pilot-operated Pressure-relief Valve

Pilot-operated Pressure-relief Valve controls the action of the main valve;

- Style of action

- Opening pressure

- Closing pressure

Valves made of Pilot Assy and main valve. Spring-loaded pressure-relief valves accept the spring’s strength in contradiction to the inlet pressure. Yet, the Pilot Assy arranges the reviving force. And they are also reseating pressure of the Pilot-operated Pressure-relief Valves. It performs almost equal to Spring-burdened pressure relief valves. However, there is no altering role in the Main Valve. Pilot-operated Pressure-relief Valves have more significant size differences than the Spring-loaded type. It is used in an authoritarian state, such as high pressure.

Dead-Weight Pressure-relief Valves

Dead-Weight Pressure-relief Valves. In this situation, the pressure vessel’s policy is fixed at external pressure. Dead-weight pressure-relief valve modifies relieving pressure solitary by the disc weight. Yet, the Vacuum release valve is appropriate for this helpful attribute. Yet it also infuses up the pressure when the pressure vessel’s inward decreases into negative pressure.

Materials Used in Boiler Safety Valves

Different materials are chosen based on their resilience to high temperatures, corrosion resistance, and other factors:

- Brass: Widely used because of its resistance to corrosion and ability to withstand moderate temperatures. It’s ideal for residential or light industrial applications.

- Stainless Steel: Chosen for high-temperature applications due to its strength and corrosion resistance.

- Bronze: A preferred choice in certain maritime or corrosive environments due to its enhanced resistance against corrosion.

- Cast Iron: Typically seen in older installations, it offers good durability but isn’t as resistant to corrosion as brass or stainless steel.

Working Pressure of Boiler Safety Valves

The working pressure of a boiler safety valve indicates the maximum pressure the valve is designed to handle. Most safety valves are designed to open when the pressure is above 3% to 5% of the set pressure and fully open at 10% over the set pressure.

- Low-Pressure Systems: These often operate at pressures below 0- 10 psi.

- Medium-Pressure Systems: Typically, these operate between 10 and 20 psi.

Manufacturers often indicate the working pressure on the safety valve itself.

Working Temperature Range

The working temperature of boiler safety valves is crucial since it determines the material to be used:

- Low-Temperature Valves: Often made of brass or bronze, suitable for temperatures up to 250°F (120°C).

- Medium-Temperature Valves: Stainless steel is typically used for systems that operate between 250°F to 450°F (120°C to 230°C).

- High-Temperature Valves: For systems that run hotter than 450°F (230°C), specialized materials or treatments may be required.

Importance of Regular Maintenance and Inspection

Ensuring the boiler safety valve is operational and in good condition is crucial. Regular inspections can prevent unexpected failures:

- Visual Inspection: Checking for visible damages or signs of wear and tear.

- Functional Tests: Testing the valve’s opening and closing mechanisms.

- Pressure Tests: To ensure the valve operates at the correct pressure points.

- Cleaning and Repair: Over time, deposits can accumulate on the valve, affecting its operation.

Choosing the Right Valve for Your Boiler

Several factors should be considered when selecting a boiler safety valve:

- Material: Based on operating temperatures and environmental factors.

- Size: Ensure it matches the boiler’s capacity.

- Set Pressure: Must be appropriate for the boiler’s maximum allowable working pressure.

- Blowdown: The difference between the set pressure and the pressure at which the valve reseats.

Selection Details

To protect your system from illogicality to overpressure. It is vital to recognize and choose the five selection criteria.

- Set pressure

- Back pressure

- Release capability

- Working temperatures

- Valve and closing material

Boiler Safety valve regulations

A boiler will be fixed with a miniature of one safety valve. Although or the valued productivity of the boiler. The release pipework from the protection valve must be accessible and exhausted. And should be at the base to avoid gathering condensate. It is decent preparation to confirm that the ejection pipework is retained. As small as possible with the lower figure of curves. So, the valve producers allowed back pressure not to exceed.

It will be pretty usual for the inside diameter of the emit pipework. It is to be extra than the interior diameter of the protection valve opening connection. But under no conditions should it be fewer.

Boiler Safety valve options and fittings

Due to the wide range of uses in which safety valves use. There are several various choices available:

Fittings and Components

- Spindle: Connects the valve head with the lever. The spindle’s movement aids in the opening and closing of the valve.

- Valve Seat: The component where the valve sits. It needs to be smooth for a perfect fit, ensuring no steam leakage.

- Guide: Helps to hold the valve spindle vertically to prevent any vibration when steam passes.

- Lifting Lever: Helps to lift the valve against the spring or weight pressure. It’s used for testing the valve’s operation.

- Surface Blowdown Assembly: A connection allowing the removal of water from the steam drum to control water quality.

- Gagging Tool: A device used to shut off the safety valve, especially during a hydrostatic test.

Selecting the Right Fittings

When choosing fittings for a boiler safety valve, consider:

- Material: Ensure it’s resistant to corrosion. Brass, bronze, stainless steel, and cast iron are popular choices.

- Size: Fittings should match the valve size and the boiler’s specifications.

- Pressure Rating: Fittings should have a pressure rating compatible with the boiler’s operating pressure.

- Thermal Expansion: Ensure fittings can handle the expansion and contraction caused by the boiler’s temperature changes.

- Connection Type: Choose between threaded connections, suitable for smaller valves, and flanged connections for larger, high-pressure boilers.

Seating material

The primary choice is the kind of seating material used. Metal-to-metal seats are made from stainless steel. Yet, it is used for high-temperature applications such as steam. The resilient discs can fit either or both of the seating surfaces. Yet, a tighter shut-off is required for gas or liquid applications. These inserts can be built from several different materials. Yet, Viton and nitrile are the most common. A soft seal insert is not generally approved for steam use.

Maintenance and Testing

Regular maintenance and testing are essential to ensure the safety valve operates effectively.

- Visual Inspection: Check for signs of wear, tear, or corrosion.

- Operational Test: Manually operate the lifting lever to ensure the valve opens and closes smoothly.

- Pressure Test: Ensure the valve operates at the correct pressure settings.

- Sealing: After maintenance, always ensure that the valve and its fittings are perfectly sealed to prevent steam leakage.

Conclusion

Boiler safety valves, with their various types and fittings, play an essential role in ensuring boiler safety by regulating internal pressure. Proper selection, installation, and maintenance of these components can mean the difference between safe operations and catastrophic failures. Always prioritize safety and quality when working with boiler safety valves and their fittings.