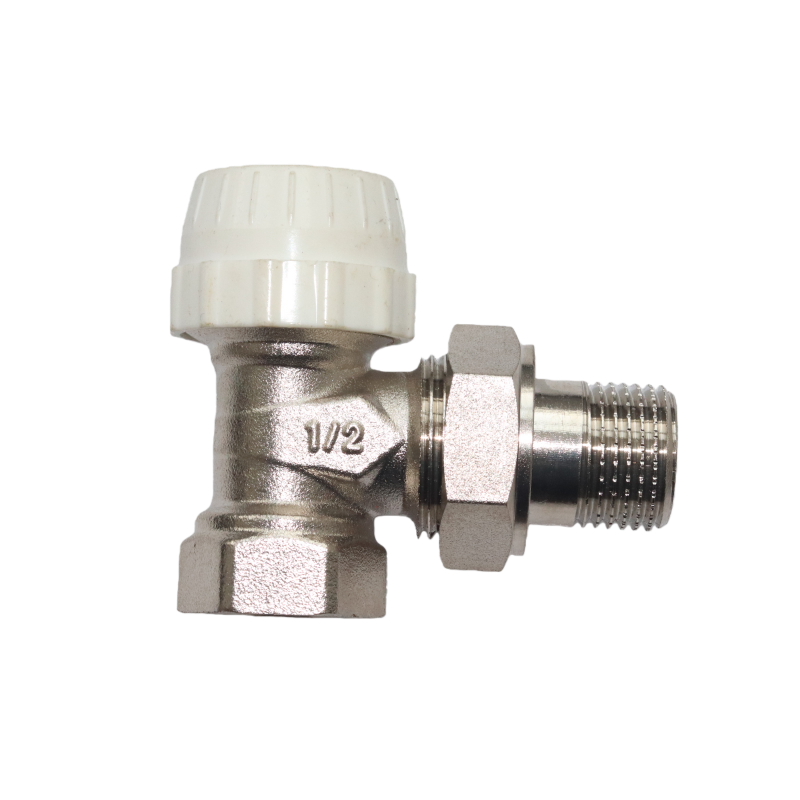

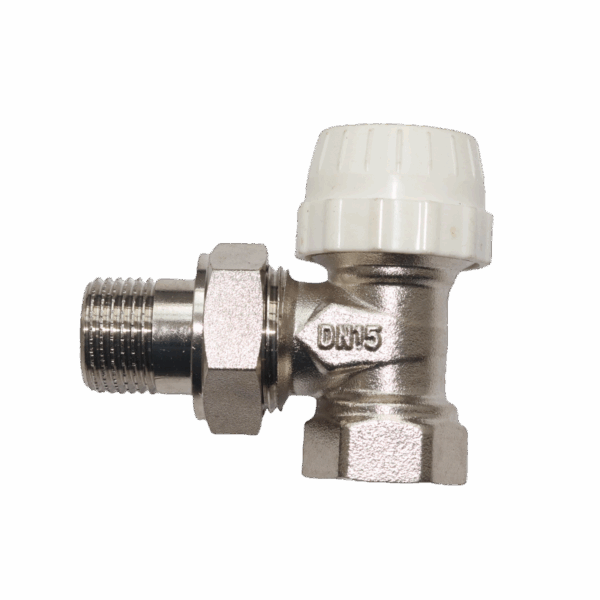

FAQs of Angle Thermostatic Valve

1. Do you offer different Angle Thermostatic Valve handle designs?

Of course! We offer a variety of handle designs and customization options for angle thermostatic valves. It can meet the needs of different bathroom styles, brand aesthetics, and market preferences. All handle styles are fully interchangeable with our standard valve body. Maintains the same high-precision temperature control performance. We have 6 mainstream standard handle designs in stock. We can also provide comprehensive customized services for OEM/ODM projects.

1. Lever handle Classic long lever design with an ergonomic grip and easy temperature adjustment. There are brass primary colors, chrome plating, brushed nickel, matte black, and other surface treatments available.

2. Round knob handle. Compact round knob style for a simple and clean look. Finish: chrome, brushed nickel, matte black, gold.

3. Cross handle Four-arm cross design, classic European retro aesthetic. Surface treatment: polished brass, antique brass, chrome plating.

4. T-handle/bar handle Straight T-bar or elongated bar handle, modern industrial style. Finish: matte black, brushed stainless steel, chrome plated.

5. Thermostatic indicator handle The handle is marked with a temperature scale (20°C–50°C) and a 38°C safety limit. It is standard in the EU and North American markets.

6. Customized logo/engraved handle: Laser engrave or etch your brand logo, model code, or pattern on the handle. Can be used with any of the above shapes of handles

2. Is it possible to request a specific RAL color for the plastic components of the Angle Thermostatic valve?

Yes, we fully support customizing the plastic components of the angle thermostatic valve to the RAL color you specify. This is a standard OEM/ODM service we provide. The main plastic components can all be produced in accordance with the precise RAL color you require. We can match the RAL color for all visible and functional plastic components on the angle thermostatic valve: temperature adjustment knobs/handle covers, 38°C safety lock covers/indicator rings, scale rings, decorative end caps/side covers, sealing caps, and non-metallic decorative components.

We use a professional spectrophotometer for color calibration to ensure that the color matching degree between the finished plastic components and the RAL color number you provide is within the range of ΔE ≤ 1.5. You only need to provide the accurate RAL number.

3. Can you produce Angle Thermostatic valves that comply with California regulations?

Yes, Plumberstar manufactures and supplies angle thermostats that are available for sale, installation, and commercial transactions in California. Fully complies with all mandatory lead-free, performance, safety, and labeling requirements in the state.

Our valves are third-party certified to meet the core regulations governing drinking water plumbing products in California:

AB 1953: Lead content ≤0.25%.

NSF/ANSI 61 and NSF/ANSI 372: Health Effects and Lead Extraction Certifications.

ASSE 1016 / ASME A112.1016 / CSA B125.16: Performance and scald protection requirements for thermostatic valves. It includes a maximum outlet temperature limit field adjustable to ≤120°F/49°C.

UPC/IPC and cUPC Certifications: Meets installation specifications in California and throughout North America.

4. Can you provide a material analysis report for each batch of Angle Thermostatic Valve used?

Yes, Plumberstar can provide a complete Material Test Report (MTR) for each batch of angle thermostatic valves you order. This is a standard service we offer. The report includes complete material composition, lead content, mechanical properties, and compliance data. All reports are traceable and specific to each batch.

Each report is unique to the batch and linked to your production batch number. It covers all key materials of the angle thermostatic valve:

1. Brass valve body

• Complete chemical composition analysis

• Actually measured lead value (typically 0.08%–0.20%)

• Tensile strength, hardness, density

• Material grade: C69300, C89510, CW617N or equivalent lead-free brass

2. Internal components (thermostatic element, valve core, spring)

• Material specifications (stainless steel grade, POM, PA66, EPDM, etc.)

• For thermostatic sensors: thermal response performance data

3. Plastic and non-metallic parts

• Heavy metal content

• Heat resistance and aging test data

4. Standard accessories included with each batch

• Batch material certificate

• Lead content test report

• Pressure test report

• Factory Quality Control (FQC) report

• If required: third-party reports from SGS, Intertek, or Bureau Veritas

5. What is your current maximum monthly production capacity specifically for angle thermostatic valves?

Currently, the maximum monthly production capacity of Plumberstar’s angle thermostatic valves, based on our dedicated valve production line in Taizhou, China, is as follows:

Standard monthly capacity: 65,000 units/month. This is our continuous and stable output under 26 working days with a 2-shift system. It covers standard models, lead-free brass valve bodies, and versions compliant with NSF/AB1953 standards. And all standard handle/surface treatment options.

Maximum monthly capacity: When adopting a 3-shift system, 24-hour production, coupled with overtime and full-line operation. The peak monthly capacity of our angle thermostatic valves can reach 91,000 units.

We can further expand production capacity by starting additional dedicated production lines. But advance planning is required.

6. Can you provide a Certificate of Origin for the Angle Thermostatic Valve?

Yes, we can provide you with a complete set of official Certificate of Origin (C/O) documents for your angle-type thermostatic valves. This is a standard export document we issue for every international order, and we do not charge you any additional fees. Depending on your destination country and tariff preference policies, we mainly issue two types of Certificates of Origin:

1. General Certificate of Origin (C/O)

Issued by the China Council for the Promotion of International Trade (CCPIT) or our company (based on the commercial invoice).

It indicates that the goods are “Made in China” and includes complete factory and production details.

Accepted by customs worldwide, it can be used for general import customs clearance.

Included contents: exporter and importer information, description of goods (angle-type thermostatic valves), HS code, quantity, invoice number and date, official seal and signature.

2. A Preferential Certificate of Origin is used to help reduce import taxes.

If your country has a free trade agreement with China, we can issue this certificate for your shipment. With this document, your goods may enjoy lower tariffs or even be tax-free when they enter your country. All certificates are officially issued by the government and are accepted by local customs, so they can be used safely for customs clearance.

7. Is the mold fee for the ODM Angle Thermostatic Valve a one-time prepaid cost?

Yes, the mold cost for the ODM angle thermostatic valve is a one-time prepaid fee. It only needs to be paid once before mold development, and no matter how many batches are ordered in the future, it will not be charged repeatedly. This is our standard policy for all customized valve and pipe fitting ODM projects. The mold cost will be quoted and collected before mold design and manufacturing. A fee is charged once for each unique set of molds (valve body mold, handle mold, plastic part mold, etc.). Future orders, restocks, or annual renewals will not be charged the mold fee repeatedly. After full payment, the mold will be reserved exclusively for your project. We provide free permanent storage, maintenance, and repair of the mold at our factory throughout its entire service life. The design of the mold can usually withstand more than 500,000 to 1,000,000 injection moldings.

For customers with very large annual purchase volumes, we may fully waive the mold fee or deduct it from future orders. If your cumulative order quantity reaches the agreed threshold (for example, 50,000 – 100,000 units), we can refund the full mold fee as a rebate or order credits (details can be negotiated according to the project).