Radiator Valve Manufacturer

Choose our high-performance Brass radiator valves crafted to meet the heating system needs of your distribution markets—excellence through Customization, our TRV boasts superior quality and performance in your competitive market.

OEM TRV -Radiator Valves

-

Angle Antique Thermostatic Radiator Valve

ADD TO QUOTE -

Forged Thermostatic Radiator Valve

ADD TO QUOTE -

Hot Water Radiator Heating System

ADD TO QUOTE -

Radiator Valve for Bathroom Towel Rail

ADD TO QUOTE -

Radiator Water Control Valve

ADD TO QUOTE -

Radiators valve For Heated Towel Rail

ADD TO QUOTE -

Temperature Heating Valve

ADD TO QUOTE -

Thermostatic Head Thermostat for towel rail radiator

ADD TO QUOTE -

Thermostatic Mixing Valve With Sensor Head

ADD TO QUOTE -

Thermostatic Radiator Head

ADD TO QUOTE -

Thermostatic Valve for Towel Radiator

ADD TO QUOTE -

TRV Heating Valve

ADD TO QUOTE -

Wifi Thermostatic Radiator Head

ADD TO QUOTE

Plumberstar-Radiator Manufacturing Companies For TRV Valve

Since 2006, Plumberstar has been a trusted brand in fabricating thermodynamic radiator valves (TRVs). With more than 17 years of experience and expertise, we focus on delivering exceptional temperature control, energy efficiency, and a comfortable living environment. Our dedication to quality and customer satisfaction has established us as a leading provider in the industry and resident plumbing systems. Choosing Plumberstar means investing in a company with a proven track record of success and a commitment to delivering top-notch TRVs tailored to your heating system needs.

Need To Know About Radiator Valves

The radiator valve controls how much hot water flows in and moves out of the radiator. Controlling this water flow changes how much heat the heater can make. The thermostat is only one way to control the overall temperature of a central heating system. The valves’ main job is managing the radiators’ temperature and requires a radiator hose to let water through the heating system.

General Applications For Radiator Valve

Standard radiator valves help control the amount of hot water that flows within a radiator to generate heat levels on a room-per-room basis. The valves ensure that the output of heat in a room is controlled. A thermostat will control the overall temperature in the house, while a radiator valve will ensure that a specific room is receiving heat. In other words, all rooms will be heated except those with completely off valves, this can save you on energy costs .

Normal Radiator Valve As Manufacturing Types

Various designs and finishes are available for the valves that control the water flow into radiators. Radiator valves, in whatever form they take, are necessary to conveniently cut off the central heating circuit’s flow into the towel radiator. Old stone structures and traditional systems still employ the wildly popular microbore radiator valve, formerly one of several entry valves.A more efficient central heating circuit and two-pipe systems were created due to radiators’ extensive usage as heating sources. You may use the valves already on your radiator with a new one, but if you’re going to be making any changes to the pipes or the radiator itself, you might have to get new ones.

Manual Radiator Valve

To maintain the flow of steam or hot water via a manual radiator valve, one must turn a lever or knob. They are unresponsive to variations in temperature since they lack automated sensors and thermostats. They provide some degree of temperature control, but you’ll have to fiddle with the knobs to keep the room at a pleasant temperature.

To control the room’s heat, most manual valves have a simple dial that can be turned from completely open to completely closed.

Thermostatic Radiator Valve

Because of its effectiveness in lowering heating costs and energy consumption, thermostatic radiator valves (TRVs) have lately experienced an enormous increase in popularity. Automatically adjusting the valve’s opening according to the ambient temperature is a built-in temperature-sensing device in TRVs. Completely automated TRVs, unlike their manual counterparts, can regulate hot water supply to keep a room at a constant temperature. Because of this, they are much more energy-efficient than manual valves.

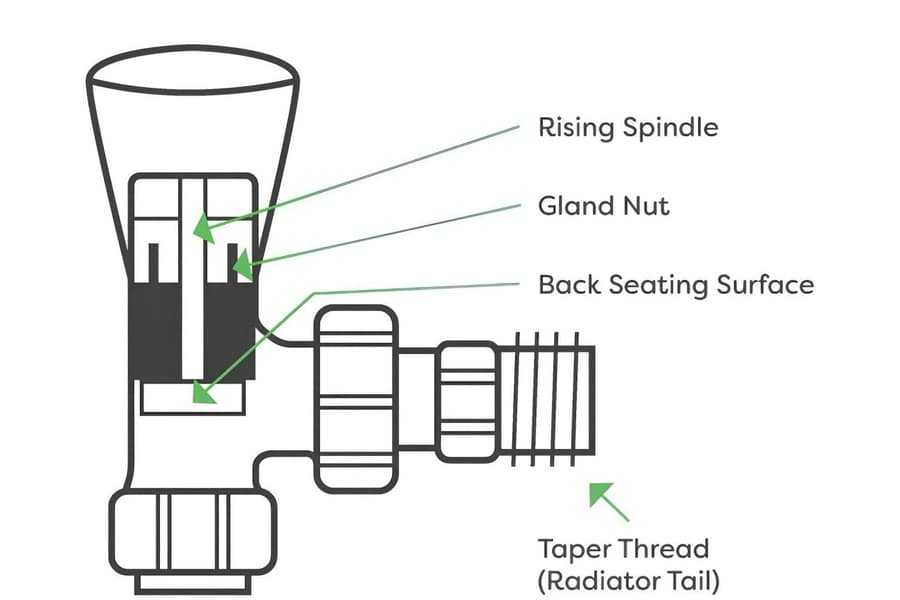

What Are the Components of Manual Radiator Valve?

A sealing material, often made from PTFE or graphite, is wrapped around the spindle on both sides to prevent leakage between the valve body and the spindle. The spindle and packing inside the valve body are held in place by the retaining nut or bonnet. It is often produced from materials designed to survive for a long time, such as brass or stainless steel, to ensure an ideal fit.

Valve Body

In addition to housing the valve mechanism, the primary component links the system to the radiator and the plumbing. It is usually crafted from stainless steel, brass, or bronze materials for longevity and corrosion resistance.

Spindle or Stem

The stem in a thermostatic valve is integral to its ability to regulate temperature. It is connected to a thermal element (like a wax thermostatic element) that expands or contracts in response to temperature changes.

Handle or knob

The valve may be manually adjusted using the user interface. To complement any design, handles are available in various styles and materials, including plastic, metal, and wooden finishes.

Gaskets and O-rings

Its primary functions are to ensure a tight seal between the valve components and to avoid leaks. Common materials used to make them include heat- and wear-resistant rubber or silicone.

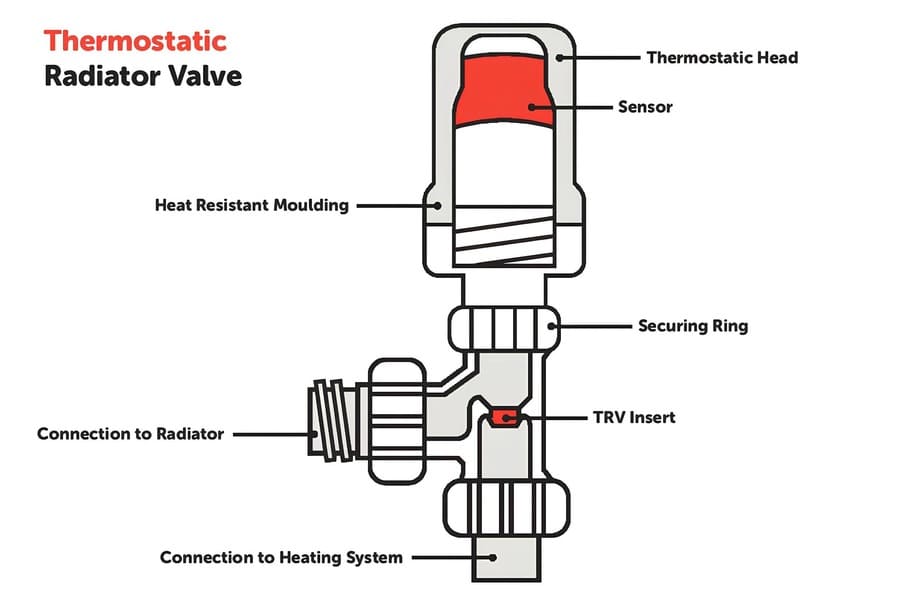

Manufacturing Components of Thermostatic Radiator Valve

Controlling the amount of hot water that flows through radiators is the primary function of both thermostatic and manual radiator valves.

Thermostatic head:

Head” signifies the valve’s knob for adjusting the temperature. This head allows for easy adjustment of the valve’s degree. This head may also include temperature sensors in some versions. Within the plastic valve, the head is where you’ll find the liquid sensor. Verify the connection points before installing the valve head.

Valve mechanisms:

TRV and manual radiator valve mechanisms are developed differently. The mechanism that permits TRVs to react to changes in temperature is more sophisticated than that of manual valves, which are operated manually.

Stem:

Some TRVs have a spindle that transfers motion from the thermostatic head to the valve mechanism. Typically, a temperature-responsive component is unnecessary for the spindle to be operated directly by hand in manual valves.

Knob:

To manually change the water flow, one may use a wheel or knob on a manual radiator valve. Because TRVs automatically adjust the water flow based on the ambient temperature, they do not need this component. Radiator valves share common replacement parts: gaskets, packing, O-rings, and retaining nuts or bonnets.

Size Guide About The Thermostatic Radiator Valve

Central heating system upgrades and installations include several considerations, including the radiator valve. The good news is that most British houses have relatively simple valve size requirements. The radiator valves are 15mm, which is the width of the connection. Copper pipes in homes are typically 15 mm in diameter.

However, there are instances when the 15mm rule does not apply, and we have included an in-depth guide to all the possible sizes of radiator valves below.

15 mm Valves: A 15mm valve should be fine for radiators in most homes since it is the average pipe size in the UK. However, you should double-check because there is a spectrum of sizes.

22 mm Valves: You may need to install larger pipes in a bathroom, as they enable a greater flow of water from the hot water tank, which is useful when a radiator’s location needs a higher water pressure.

10mm Valves: While 10mm pipes throughout a home are uncommon, these valves might be required to connect a single radiator to your current heating system.

8 mm Valves: Microbore pipes, popular for homes constructed in the middle to late 20th century, use 8mm valves and are, unfortunately, more prone to obstructions and pipe kinks.

How to Check in Thermostatic Radiator Valve While Choosing?

Thermostatic Radiator Valves (TRVs) are designed to control the flow of water in the radiator depending on the ambient temperature. For them to function effectively and safely, they are manufactured to operate within certain temperature and pressure limits.

TRVs may be found in various finishes, including plastic, chrome, brass, nickel, etc. Aesthetic considerations may play a role in selecting the design and coating. Some valves can handle both flow directions, and others are direction-specific. The installation of the valve on the radiator is affected by this. You may get TRVs with fixed heads and those with interchangeable heads. The actual thermostat mechanism is located in the head. TRVs are available in straight, angled, and corner orientations to accommodate a wide range of radiator and pipe layouts. Determining the current valve or pipe connection size is crucial when choosing a TRV size. Seek advice from a heating expert or the valve maker if you are uncertain about the correct size.

Standard Working Pressure and Temperature Require for Thermostatic Radiator Valves

Thermostatic Radiator Valves (TRVs) are designed to control the flow of water in the radiator depending on the ambient temperature. For them to function effectively and safely, they are manufactured to operate within certain temperature and pressure limits.

Standard Temperature Range:

A straight thermostatic radiator valve’s typical operating temperature range is 0 to 28°C. Some models can function at temperatures ranging from -10 °C to 30 °C. Depending on the system type and user’s preferences, the valve may be changed to different degrees. However, the commonly acknowledged lower temperature setting is 15 degrees. The user may adjust the degree of the valve to suit their tastes or specific medical needs.

Changing the valves is easy to adjust The screw on the valve’s base allows you to adjust the minimum flow. The change enables a more rapid reaction to variations in temperature. You may change the degree using the valve’s settings, which range from 1 to 5. The sensor has an adjustable dial that you may use to change the temperature. Although many TRVs have a minimum working temperature of around 0°C (32°F), it is important to remember that they are not intended to avoid freezing. Antifreeze substances or pipe insulation are some options to consider if freezing is a risk.

Pressure Range for TRVs:

Residential thermostatic radiator valves (TRVs) are typically designed to function between the pressure range of 10 bar (145 psi) to 16 bar (232 psi). In a typical residential central heating system, the pressure often ranges from 1.5 bar (21.75 psi) to 3 bar (43.5 psi).

Maximum Pressure:

The maximum operating pressure of thermostatic radiator valves (TRVs) often varies. While a limited selection of high-performance TRVsis is capable of withstanding pressures up to 20 bar (290 psi), their availability is mostly restricted to specific commercial applications rather than readily accessible in the general market.

Different TRV types and makers may suggest different pressure and temperature ranges. It is essential to thoroughly review the radiator valve manufacturer’s specifications before proceeding with any installation or modification. Select a thermostatic radiator valve (TRV) that can effectively manage the heating system’s distinctive operational conditions, particularly when it operates beyond its typical restrictions.

Non-Settable and Pre-set Radiator Valve

A Pre-set Thermostatic Radiator Valve (PRTV) is a specific type of Thermostatic Radiator Valve (TRV) with added functionality to allow for pre-setting the maximum flow of water through the radiator.

The only purpose of a non-setting radiator valve is to open and close the valve. The importance of efficient hydraulics, defined as the optimal flow behavior of heating water in a heating system, has grown over the last several decades due to the growing need to save energy. In this case, presettable radiator valves—which can do more than just open and close—come into play. Accomplishing hydraulic balancing with radiator valves that are adjusted in advance is feasible.

It is possible to specify the precise quantity of water for each radiator using the Pre-setting key to pre-set the valves. The flow area at the valve’s cross-section is reduced to accomplish this. This ensures the radiators never run out of hot water or have too much.

Pre-set Radiator Valves With Differential Pressure Control:

Radiator valves pre-set with an internal differential pressure control are an improvement above standard radiator valves. When operating at partial load, the hydraulic balance of the heating system is further optimized by internal differential pressure management.

Because hydraulic balancing volumetric flow rate calculations are usually done for the full system load situation, the hydraulics may not always work at their best under the partial system load scenario. Due to the varying volumetric flow rates, the heating system experiences various pressure conditions during part-load and full-load operations. To prevent radiators from overheating, PRTVs control and restrict the water flow. Heating costs might go down as a consequence of substantial energy savings.The central heating system may last longer with PRTVs installed because they maintain a balanced flow and avoid overheating.

PRTVs might help develop a balanced heating system. When the system is well-balanced, the home’s radiators heat up evenly, and there are no frosty areas. Even while PRTVs need proper setup during installation, their user-friendly design makes it easy for plumbers and heating specialists to do the job quickly and effectively. Comfortable living is enhanced by PRTVs since they keep the temperature stable and according to your preferences.

PRTVs offer many benefits, and correctly installing and adjusting them is essential. The pre-setting should be based on the requirements of the specific radiator and room size. It’s also important to check them periodically to ensure they function correctly, especially before colder months start.

Why Choose to (Thermostat) Radiator Valve

- Preventing overheating

One way to keep rooms from being too hot is to install radiator valves, particularly thermostatic ones. The valve will start to shut, decreasing the flow of hot water once the appropriate temperature is attained.

- Balancing the system

The distribution of hot water may be more evenly distributed with the use of radiator valves in systems that use many radiators. You may ensure heat is spread properly throughout your house by changing the valves.

- Controls the temperature

You may adjust the temperature in certain rooms or sections of your house using radiator valves. You may control the amount of heat that radiates into the room by changing the valve that maintain the flow of hot water into the radiator.

- Conservation of energy

By letting you adjust the temperature to suit requirements, radiator valves help with energy economy. To lower the heat output in an empty room or one that gets a lot of natural light, you may partly close the valve, for instance.

- Comfort and customization

The ability to individually control the temperature in each room greatly improves the coziness of your home. The heat may be adjusted to suit each person’s desire, making it more comfortable.

- Zoning

Room size, insulation, and occupancy level are some variables that affect how much heat a room needs. You may modify the heat output in each room separately using radiator valves, allowing you to create heating zones.

How Do Radiator Valves Work?

Manual Radiator Valves Working:

Why do it manually when you can do it technically? Simply, two technological devices attempting to accomplish the same objective may encounter conflicts. Grey radiator with a manual radiator valve This means that if you have a room with both a thermostat control for the main boiler (typically a small box mounted on the wall or the mantle, which you can adjust) and a radiator valve, then using a thermostatic radiator valve in this scenario will result in a collision and conflict between the two pieces of technology.

Thermostatic Radiator Valves Working:

When the desired room temperature has been reached, thermostatic radiator valves employ ingenious mechanisms, which may consist of liquid or wax. These mechanisms deactivate the supply of hot water to a particular radiator. Installing thermostatic radiator valves is similar to having a boiler thermostat control in each room; however, they do not directly interact with the boiler. They accelerate the heating process by cutting off the water supply to their radiators earlier. This results in your boiler turning off more quickly, which simultaneously helps you save money, reduce your carbon imprint, and achieve the desired level of comfort.

What The Numbers On Radiator Valves Mean?

Numbers or symbols on radiator valves indicate the heat the radiator releases. These numerals typically range from 1 to 6. Adjusting the valve to 3 should produce an approximate normal temperature of 20°C. Consequently, each positive or negative value corresponds to an individual degree. Therefore, a 2 is roughly 16°C, and a four is approximately 24°C. Given the uncertainty of the room temperature, this number system is employed instead of precise temperatures.

Factors to Consider While Order Thermostatic Radiator Valves

The valve head of the radiator is a vital component of every thermostatic valve. Functionally, aesthetically, and structurally, they are dissimilar. Undoubtedly, the primary determinant is the element’s functionality.

Material

Durability pertains to both components that comprise a thermostatic radiator valve. Additionally, do not disregard the content of the cranium. It is possible that a model that is aesthetically pleasing.

Quality

Wholesalers and distributors must ensure the quality of the acquired thermostatic radiator valves. Using resilient and meticulously designed valves will lessen customer discontent and reduce product returns.

Extent Of Regulation

The majority of standard thermostatic radiator valves have a comparable degree of regulation. Observe the symbols that are displayed on the cranium. In addition, the visual appeal of the markings is a critical factor.

Capability Of Flow

Radiator thermostatic valves feature a variety of flow capabilities. This parameter is often disregarded when acquiring a new element, particularly by individuals lacking experience operating such a device.

General Process Fabricate for Heating Valves

Other Types of Radiator Valve

Smart Radiator Valves

With a smart thermostat that’s WiFi-enabled, you can manage your heating system from any smart device with an app. If your smart thermostat is TRV-compatible, you’ll be able to manage all of your smart home devices from the convenience of your smartphone, no matter where you are.

Angled Radiator Valves

These are necessary if the pipes must be bent at an angle, often 90 degrees, to reach the radiator. Since most towel rail plumbing originates from the floor, it is common for bathroom radiators to have a bottom radiator valve intake. The angled valve is one of the most prevalent kinds of radiator valves used for contemporary home heating.

Straight Radiator Valves

These are used when the pipes that connect the intake to the radiator have a straight course along the floor or wall. A straight valve is necessary if the connection between the radiator, the valve, and the pipe is straight.

Corner Radiator Valves

An ideal location for a corner radiator valve would be where the radiator pipes exit the wall. A corner valve may do the same thing as an angled radiator valve. Still, it’s a little more delicate and sometimes smaller.

Thermostat Radiator Valve

- 1/2 inch,3/4 inch,1 inch

- CW602N,DR brass

- Brass body

- Thermo Actuat header with EU approved

Thermostatic Radiator Valves (TRVs) are an essential component in modern heating systems, designed to regulate the temperature of individual rooms by controlling the flow of hot water through radiators.

Staright Radiator Valve

- Radiator valve with 1/2"-1"

- 2 years warranty with the actuator

- Brass body with sand blasted with nickel plated

- Hot water and cold water are available

Connection type: TRVs can have compression or push-fit connections and thread. Which need to be compatible with the radiator and pipework for proper installation.

Sensor: The TRV’s sensor is either a liquid-filled or gas-filled element that responds to changes in ambient temperature and adjusts the valve accordingly.

Brass Vertical Manual Radiator Valve

- 3/8 inch,1/2 inch,3/4 inch

- Advanced Chrome plated finish

- Cartridge Pre-setting

- 100% water leakage test

Pipe size: Usually measured in inches or millimeters. Common pipe sizes include 15mm (1/2 inch) and 22mm (3/4 inch) in diameter.

Thread size: The thread size refers to the connection point between the TRV and the radiator. It is typically measured in British Standard Pipe (BSP) threads, with 1/2″ BSP being the most common size.

Certification: The European EN 215 standard.

How To Install TRV?

You may attach most modern thermostatic valves to your radiator’s return or flow pipe; they are bidirectional. We recommend attaching the TRV to the flow pipe, which is responsible for transporting water to your input valve. Wonder why? As the water flows through a non-bidirectional thermostatic valve that you attached to the return pipe, you could later notice that it makes a loud, vibrating noise. One radiator and a room thermostat are all needed to regulate the temperature in a two-room apartment.

Drain the radiator, turn off the water supply, and Install The TRV Tail

A lot of water will be on your hands if you don’t drain the radiator before removing the present valves. Plus, the dirty water has been sitting in the radiator for quite some time.

Using one of the four valve positions on the radiator, screw the valve tail into place. Unlike other components, this one doesn’t always have a smooth surface that a standard tool can grip. Consequently, a radiator key is often required to tighten the valve tail.

The tailpiece often has a square or hex socket that this key is threaded into. A black rubber ring is a seal if it comes with a tail. Installing the seal is as easy as tightening the nut until the seal is compressed, resulting in a seal impervious to water. PTFE tape or pipe sealing cable might be used without a rubber seal.

Both straight and angled (90 degrees) TRVs are possible. Based on where your pipes are located, choose the one that will work best for your installation.

There will be a male and a female end to the rad valve. You must attach the male thread to the radiator’s tailpiece and the female thread to the hot water supply.Before fitting the TRV into position, ensure the hot water supply has a male thread and wrap it with PTFE tape. Before tightening, double-check that the TRV’s head is in the right place. The aesthetic appeal of a rad valve increases when it is either horizontally or vertically oriented correctly.Secure the nut onto the TRV’s male end using water pump pliers. This connection does not need a seal. A compression fitting, which involves compressing metal components to form a seal, is used by this component.

Set Up The TRV And Link The Water Radiator

The substitute TRV may not always be able to fit into the existing valve insert. Since they replace the insert in every new TRV, you may need to remove the old one. Loosen the component by inserting a basic hex tool into the hole and using an adjustable spanner. Next, encase the replacement insert with PTFE, put it into the radiator, and secure it. You can use the original nut and olive just fine, but if you’d want to swap them out, you can remove the nut with a nut and the olive with grips.

To ensure the fresh olive is completely sealed, wrap it in some PTFE. Reinstall the fitting and secure the bottom joint. After double-checking that everything is snug, remove the plastic valve cap. Verify that it moves correctly by pressing it up and down. Put and adjust the TRV head unit. At this point, the TRV should be working.

Attach the TRV to the Radiator

Attaching a Thermostatic Radiator Valve (TRV) to a radiator is a task that can typically be done by someone with basic DIY skills, but it’s important to follow the correct steps to ensure it functions properly and safely. Here’s a general guide to help you:

Termostatic Radiator Valve Manufactured & Production Flow

The manufacturing process of a radiator valve encompasses many steps, beginning with the design phase and the buy of raw materials and finishing with the assembly of the finished product and the implementation of quality control measures. The following is a comprehensive overview of the manufacturing process:

Step 1: Design for TRV

Radiator valves, employed in various applications, including power plants and oil refineries, should be the product of their design drawings. Here are the procedures we use while sketching ideas: First, we need to know what kind of valve has to be constructed; this will tell us how many pieces there will be. Then, we utilize computer-aided design (CAD) software to make flat drawings. We consider our budget and schedule restrictions when deciding which materials to employ. After deciding, we place an order with suppliers for the required components. After everything was delivered, we continued using the CAD program to assemble them.

Step 2: Obtaining Radiator Valve Raw Materials

Depending on the needs and kind of valve, producers purchase raw materials like brass, steel, or plastic based on the design. To begin production, the raw materials must first be prepared. Copper and zinc combine to produce alloys, which may be formed by cutting, bending, or manipulating the materials. Some of the increased properties of brass alloys are strength, machinability, corrosion resistance, and malleability. There are a variety of brass alloys made with varying proportions of copper and zinc, each with its own set of desirable characteristics.

Step 3: Radiator Valve Forging Process

The material already shaped is compressed with a forging press, hammer, or other tool. Refining the grain and causing other metallurgical changes, the applied force reshapes the material into the required form, increasing its strength and durability. Radiator valves made by forging are strong and long-lasting, so they can handle the rough use they get. The result is a product that reliably performs during its lifetime and matches all specified requirements since every stage of the process is managed.

Step 4. Machining and Fabrication For TRV

At this point, the materials are expertly cut and assembled into the radiator valve’s constituent parts. According to the needs of the component and the material, several processes like turning, milling, drilling, or injection molding are used. At this stage, accuracy and precision are of the utmost importance since the valve’s function depends on each part meeting precise requirements. There are a variety of surface treatments that radiator valve components may go through to improve their look, corrosion resistance, or other practical qualities. These processes are examples of plating, anodizing, and polishing. In addition to enhancing the product’s visual appeal, these treatments help it last longer in various operational conditions.

Step 5: Radiator Valve Assembly and Inspection

In this step, you’ll assemble a radiator valve from its parts. Several procedures, such as brazing, fastening, or welding, may be applied depending on the design and materials utilized. The safe and proper operation of the valve depends on its perfect installation.

Quality assurance and testing: Each radiator valve undergoes extensive testing to satisfy all performance and safety requirements. This thorough assessment could include leak, functional, and pressure testing to ensure every valve is effective and reliable.

How We Export the Radiator Valves?

Radiator valves are carefully packed for shipment after passing the quality control inspections. This entails wrapping the valves in foam or bubble wrap and then putting them in strong boxes or crates to prevent damage while in transport.

The radiator valves are prepared and sent to either distributors, wholesalers, or consumers based on the manufacturer’s chosen distribution method. To ensure their items’ safe and timely delivery, manufacturers collaborate closely with reliable logistics partners.

The manufacturer’s dedication to its customers is evident in its post-sale support, which includes continuing technical assistance, product training, and customer service. By providing these services, they ensure the radiator valves keep working properly for as long as the customer wants them to, which keeps them satisfied and helps them build partnerships

Exporting radiator valves, particularly from a manufacturing standpoint like Plumberstar, involves a series of strategic steps to ensure a smooth and efficient process.

Recognizing High-Quality Radiator Valves

Finding high-quality radiator valves may be challenging since, superficially, even low-quality valves might pass for high-quality ones. The outside coating of most items makes it hard to tell which ones are better; nevertheless, the valve in the interior tells you whether it’s up to the job.

When hot water enters and exits the radiator, the ideal radiator valve should have a high brass content. Radiator valves of brass have a higher-than-average resistance to erosion issues caused by wear and tear over time, which is one of many reasons this metal is so desirable. Another reason is that brass is softer than many other variants of copper and zinc.

Regardless, valves made of even brass may deteriorate due to a procedure that removes zinc while leaving the copper structure intact, which can cause the valves to fail. The manufacturing cost is a major factor in why certain radiator valves are defective while others are not.

Producing radiator valves that seem the part is a huge priority for manufacturers, regardless of how useful they may be. There’s a simple technique to tell whether your radiator valve is good quality.

According to European and British norms, Standard radiator valve weights range from 750 to 1000 grams (g), depending on the type. The fact that cheaper versions could weigh 500g or less indicates that they are more prone to future leaks and issues. So, as a general rule, it’s a good idea to inquire about the weight of the valves when you buy new radiator valves.

The Common Pitfalls While Purchasing Radiator Valve

When it comes to bulk purchasing radiator valves, buyers face a unique set of challenges. Understanding these pitfalls is crucial to make informed decisions and ensure a successful investment. Here’s what you need to know:

- Actuator head get stuck while switch

- No test pneumatique

- No test hydraulique

- No test founctionnel

- No air leakage test

A type of valve used in heating systems to control the flow of steam or hot water is known as a bi-directional radiator valve. Traditional on/off valves provide a lower degree of control than these valves, which allows for more precise control over temperature and energy efficiency. These valves give a higher level of control. Depending on the desired temperature, bi-directional radiator valves may be changed to allow for either an increase or a reduction in flow. Because of this, they are ideal for rooms with wide windows or doors and need a temperature that is more stable throughout the day.

The pressure release buttons and check valves integrated into these valves are additional safety precautions built into the valves themselves. As a result, this ensures that any excess pressure is released before it can harm the system. Take notice that bi-directional radiator valves are inappropriate for all heating systems. This is an essential point to keep in mind. In sealed systems with components that are compatible with one another, they should only be utilized. In addition, it is essential to do routine maintenance to ensure the correct operation of your house and to guarantee the safety of everyone who lives there.

Step 1: Prepare Your Workspace

Before doing anything else, gather old sheets, towels, and whatever else you need to cover any potential spills. The water that drains from your radiator may not be clean, spoiler warning!

Step 2: Disconnect the Water and Heat Source

Hold off on turning off the water and heating until the radiators have cooled completely. Here, you should also ensure that the thermostat is off and that no heating programs are running since they might interfere with replacing the valves.

Step 3: Drain Your Heating System

Even while it may seem difficult, this is very simple. Finding the drain cock in your house is the only complicated part; after that, you may attach the hose and fasten it with the jubilee clip. The next step is to open the drain cock, take the hose outdoors, and let the water drain completely.

Step 4: Remove Your Old Valve

Remove the old valve from the radiator, and use the wrench to grip its body and the spanner to unscrew it. You may have to remove the valve adapter if you need to change it.

Step 5: Place Your New Valve

After you’ve cleaned the pipe and valve, replace it with the new one and screw it back onto the radiator. Secure the water pipe using the plumber’s tape to prevent leaks further. While tightly fastening the valve to the pipe, be careful not to over-tighten it.

Step 6: Turn Your Water And Heating Back On And Refill Your System

While this step should be obvious, remember that you want the pressure gauge to return to 1.5 before refilling your boiler system.

Step 7: Bleed your Radiator

make sure that your efforts are not in vain; this is a necessary step to release any gas that may have been trapped within the radiator. A detailed tutorial on bleeding radiators is available. After bleeding the radiator, you may need to replenish the pressurized system.

How to Change A Radiator Valve

To successfully change your radiator valves and minimize mess, here’s a handy checklist of what you’ll need before changing a radiator valve.

New radiator valves

Old towels or sheets

An adjustable spanner or star key

A wrench

Plumber’s tape

A hosepipe or large container

A radiator bleed key

Factory Self-Nomination, Why Choose Plumberstar?

Plumberstar is a radiator valve manufacturer with exceptional proficiency in producing personalized valve and pipe fitting solutions for residential applications. We take great pride in our extensive selection of heating products, including radiator valves that serve as important elements within heating systems of utmost quality. Our radiator valves are specifically engineered to effectively control the water flow into the radiators, maintaining a consistently warm and pleasant environment inside your residence throughout the year. The process of selecting an appropriate radiator valve may be challenging. We have meticulously curated a collection of the most exceptional items to address this concern.

The manufacturing range includes thermostatic radiators, manual and angled valves, and radiator hoses to meet your needs. Our team of experts is always available to provide advice and support, assisting you in selecting the appropriate valve that aligns with your requirements and financial considerations.

The FAQs About Manufacture and Import Radiator Valves

One of the most common issues homeowners face is a faulty radiator valve. If your radiator isn’t heating up properly, it could be because of a problem with the valve.

How to Test the TRV Valve?

TRV valves are a category of water heater components. They modulate the pressure between the reservoir and the tap in addition to the passage of hot and cold water. Defective or worn-out valves have the potential to result in elevated utility expenses due to their impaired functionality. To prevent further damage, it is critical to have your TRV valve replaced immediately if you discover malfunctioning.

A TRV valve is an autonomously opening reverse-acting pressure, and temperature relief device triggered when the system reaches its predetermined setpoint. These procedures make testing TRV valves simple.

The procedures are as follows: 1) Inspect for visible damage, and 2) If no visible injury is present, determine whether or not it can be opened with pressure. 3) Once it becomes immobile, substitute the TRV valve. 4) If there are no observable defects or the thermostat can be opened, it is advisable to contemplate replacement as the thermostat may be defective.

Is It Worth Getting Thermostatic Radiator Valves?

Indeed, thermostatic radiator valves are well worth the investment when utilized properly. Utilizing thermostatic radiator valves efficiently is estimated to reduce energy consumption by as much as forty percent, leading to substantially reduced energy bills. In addition to their cost-effective advantages, thermostatic radiator valves can increase indoor comfort. This is achieved by providing individual radiator temperature settings, which not only aids in the maintenance of desired conditions but also contributes to energy conservation by permitting the deactivation of radiators in unoccupied rooms.

What Are The Settings On The TRV Thermostat Used For?

TRVs are constructed with various temperature settings to enable the maintenance of distinct room temperatures in individual rooms and the energy-saving deactivation of unused spaces. However, the boiler must supply hot water for the TRV to heat the radiator. The TRV's case frequently will not feature a temperature setting but rather a range of numbers indicating whether the adjacent area receives more heat (high number) or less heat (low number).

Does The Location of The TRV Installation Matter?

TRVS must be installed in a "free air" environment, unobstructed by obstructions such as decorative cabinets, furniture, or draperies to ensure optimal control and energy efficiency. As the TRV is only sensitive to the temperature it can detect, it cannot accurately regulate the room temperature if it is covered; therefore, the room may be underheated or overheated.

Why Should I Install A Plumberstar TRV?

Plumberstar's goal is to provide the most energy-efficient products possible; therefore, our products are engineered to offer comfort and control levels that complement our commitment to energy efficiency. We consistently strive to collaborate with esteemed classification systems to showcase our products' efficacy effectively. The European TELL certification educates consumers about product selection and encourages the adoption of responsible energy practices.

Should I Consider Replacing My Existing TRVs?

Because old TRVs may decline in performance and accuracy over time, you should consider upgrading at least the TRV heads if your TRVs are older than ten years. This can be accomplished frequently without replacing the bodies or exhausting the system; TRV heads are compatible with bodies from various manufacturers; alternative adaptors are available for those that do not.

What Types of Radiator Valves Can I Buy?

At an angle of approximately 90°, angled radiator valves connect the radiator to the heating pipelines.

Typically connected from the floor to the radiator and pipelines, straight radiator valves guarantee that water circulates linearly.

Corner radiator valves resemble angler radiator valves, except they protrude less into the lavatory.

Manual radiator valves permit temperature regulation of the radiator through manual means. Simply toggle the device on and off as desired.

The room's temperature is maintained constantly by thermostatic radiator valves.

How Can I Determine Which Radiator Valve Variety Is Ideal For My Home?

The optimal radiator valve for your home will depend on various factors, including the dimensions and configuration of your dwelling and the degree of temperature regulation you require in specific rooms. Manual valves, for example, are typically the most economical alternative. However, they may need to achieve the same precision as more modern valves, including thermostatic or motorized models. When the heating system is switched on, these devices maintain the room's temperature, which can be ineffective if a window is opened to reduce the temperature. Although thermostatic designs are comparatively costlier, they offer superior temperature regulation due to their omission of excessive heating.