Description

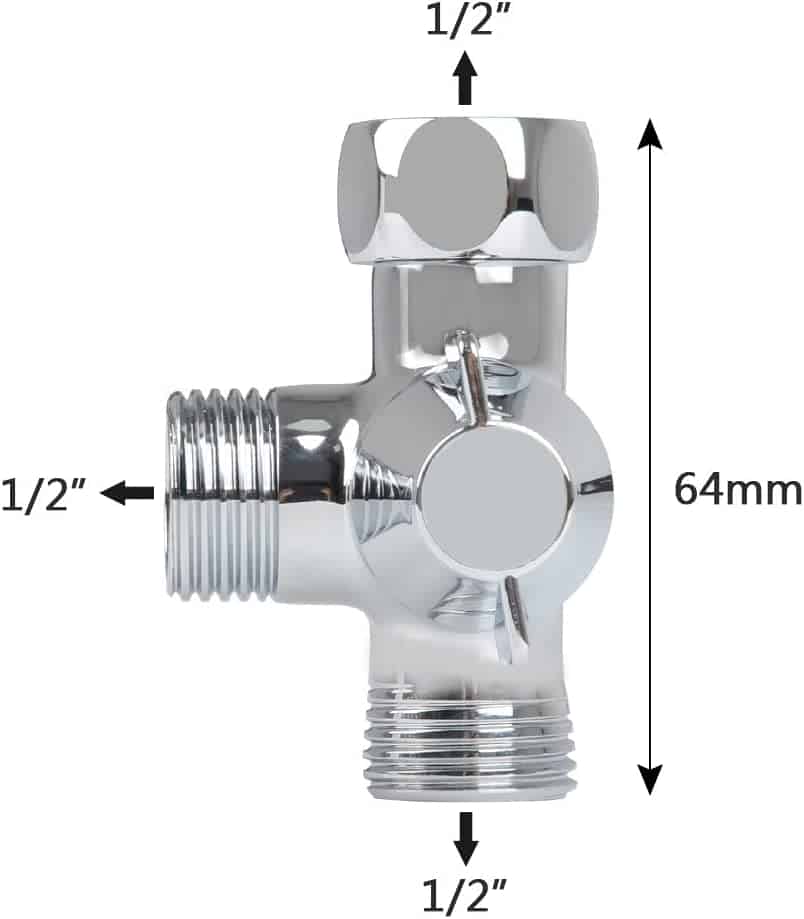

3-Way Shower Diverter Valve

JX-0207

- Size 1/2″ X 1/2″

- Stainless steel body and handle.

- The black color with a coating

- Brass cartridge with fast-open

- It’s with plastic bag packing by each.

- Three million times open-off working is guaranteed.

- Shower head diverter valve with 1/2″ female inlet and 1/2″ male outlet. It can meet your applications.

- The shower diverter can be connected to shower heads, arms, and shower hose at the same time, 1/4 rotation handle turn valve, free to switch the direction of water flow.

- One end is connected to the shower head, one to the arm, and the last to the hand shower.

- This shower adapter is made of brass and ceramic spool and has a long service life. With a chrome-plated surface, this T shower adapter can avoid scratches and be anti-rust.

toilet stainless steel angle valve

toilet stainless steel angle valve

What is a Diverter Valve?

A diverter valve is an essential component of any shower system. It is a valve that routes water from the main supply line to multiple outlets, such as a shower head and a hand-held sprayer. A 3-way diverter valve takes advantage of this functionality by adding an extra outlet, allowing you to use all three simultaneously.

These valves are made from durable materials like brass or stainless steel and come in various sizes and shapes. They also vary in price depending on the type, quality, and features they offer. Installation requires basic plumbing knowledge but can be done easily if you follow instructions carefully. They will provide reliable service for many years without issues or maintenance required when properly installed.

Types of Diverter Valves

A 3-way shower diverter valve is an essential element of any bathroom’s water system, allowing easy switching between different water sources or outlets. But did you know that several types of diverter valves are available to choose from? Knowing their differences can help you decide which is right for your needs.

The most common type is a basic 2-way diverter valve – also known as a spool or T-valve – which allows users to easily switch between either two outlets or a combination of both. This type of valve works best when there are only two outlets and minimal pressure difference, such as in a standard shower head and handheld sprayer setup. However, another diverter valve may be necessary for more complex multiple-outlet systems.

Installation Considerations

Before installing a 3-way shower diverter valve, there are several important considerations to make. The first thing to consider is the size of the shower diverter valve. Make sure to measure the distance between the two ports on your existing plumbing system and choose a 3-way diverter valve that will fit in this space. Additionally, it’s important to ensure that you have the necessary tools and materials before beginning installation. This includes a wrench, plumber’s tape, silicone caulk, and an adjustable pipe cutter or hacksaw. Finally, read the manufacturer’s instructions carefully before installation begins to avoid any mistakes or costly errors down the line. With these simple tips in mind, installing a 3-way shower diverter valve should be quick and hassle-free.

Benefits of 3-Way Shower Diverter Valve

The 3-way shower diverter valve is an essential part of a well-functioning bathroom. It provides access to multiple water sources and allows easy control over the shower’s water flow. This type of valve can switch between two separate water supplies, such as those from a bathtub and a handheld shower head, or even two different showers. The diverter valve also offers several benefits, making it a great choice for any bathroom installation.

One benefit of using a 3-way shower diverter valve is its ability to help conserve water by allowing users to adjust the flow rate accordingly. By controlling how much water is released at one time, it’s possible to reduce unnecessary waste while still enjoying powerful showers. Additionally, this type of valve makes it easier to customize the overall design of your bathroom setup and ensure everything works together seamlessly.

Maintenance and Troubleshooting Tips

When your 3-way shower diverter valve stops functioning properly, it can be a real pain. But with the right maintenance and troubleshooting tips, you can keep your shower in top condition. Regularly cleaning and properly maintaining your 3-way diverter valve is essential for keeping it in good working order. To ensure that this important part of your plumbing system remains operational, follow these simple steps to maintain and troubleshoot it.

First, flush out the water from the valve by turning on all three handles for about five minutes each week. This will help remove any sediment or buildup accumulated over time. Secondly, check for leaks around the handle seals or gaskets and replace them when worn out or torn.

Conclusion: Advantages of Installing a 3-Way Shower Diverter Valve

The installation of a 3-Way Shower Diverter Valve is an advantageous addition to any shower. This type of valve allows for the easy switch between three distinct shower functions – a hand-held unit, body jets, or a rain shower head. Installing this type of valve presents several benefits that make it well worth the time and effort involved in its installation.

First and foremost, the 3-Way Shower Diverter Valve provides flexibility for users who may want to change up their shower experience from time to time. The ability to easily switch between the different functions will make it easier for people with limited mobility or those with special needs to comfortably enjoy their showers. Additionally, this type of valve also makes it easier for multiple people in one household to customize their showers without installing completely separate fixtures.

Types of stop angle valves

There are three stop angle valves- the ball valve, the butterfly valve, and the plug valve. Ball valves are the most common type of stop-angle valve. They are quarter-turn valves with a ball with a hole in the center that controls the water flow. Butterfly valves have a disc that turns to open or close the valve. Plug valves have a plug that moves up and down to open or close the valve.

Why use stainless steel?

There are many reasons to choose stainless steel for your stop angle valve. Stainless steel is an incredibly durable material that will withstand corrosion and rust. It is also a very low-maintenance material, so you won’t have to worry about rusting or corroding over time. Stainless steel is a very strong material that can handle high temperatures and pressures.

Advantages of stainless steel stop angle valves

A stainless steel stop angle valve is a type of valve used to control the flow of liquids and gases. It comprises a body, a bonnet, a disc, and a stem. The valve’s body is usually cast iron, ductile iron, or cast steel. The bonnet is cast iron, ductile iron, or forged steel. The disc is usually made from stainless steel. The stem is typically made from stainless steel or brass.

Brass with zinc Alloy:

The product contains a body of Brass coated with zinc alloy for such valves. This mixture serves a lot of benefits for users. Zinc alloy has the following impressive features.

- They can maintain their performance for a very long time.

- Zinc alloy angle valves are more effective for hot water operations than metal.

- They have a striking ability to bear high-temperature conditions.

- Zinc alloys offer high resistance to corrosion environments.

Besides many advantages, zinc alloy valves are expensive and need regular maintenance.

On the other hand, Brass is even more suitable for angle valves. The combination of brass and zinc alloy creates a durable product with both metals’ features.

- Brass is also a high corrosion resistance material.

- Brass valves have a very long life and aren’t easily damaged.

- Brass is easy to maintain.

- Brass can tolerate a very high-temperature level. This level is often not bearable for most metals.

Due to these features, industrial dealers prefer Brass. They stay longer and need less maintenance. It is an impressive feature and has led to the extreme popularity of this product.

Shut-off Angle Valve Parts from Plumberstar

| No. | Part | Materials |

| 1 | Body | Brass |

| 2 | Cartridge | Brass |

| 3 | Stem | Brass |

| 4 | Seal | EPDM/cartridge |

| 5 | Seal Gasket | Washer |

| 6 | O ring | NBR |

| 7 | Thread | BSP, G 1/2″x1/2″x1/2″ |

| 8 | Handle Wheel | Stainless steel, Plastic |

| 9 | Finish | Polishing, CP, Painting |

Plastic Angle Valve:

Plastic is now more widely known for sanitary products. They are easily accessible to everyone. Following are the benefits of using plastic angle valves.

- Plastic valves cost less than metallic valves.

- They give an attractive look to the valve.

- You can find and operate them efficiently.

- They are lightweight. It means it can be easy to handle in the case of far-off exporting.

Yet, plastic valves have fewer limitations than metallic valves. Plastic valves cannot undergo high-temperature conditions. In such cases, they melt away and can create trouble. Plastic valves are less likely to survive longer because of their delicate nature. We cannot use plastic valves for industrial purposes as they cannot hold enough pressure and burst out. Chemical and acidic fluids cannot operate using a plastic valve.

Still, for many reasons, plastic valves can be a good option for household use in bathrooms and the kitchen. They can survive there with ease.

Read more on The Advantages and Disadvantages of plastic valves.