What Is a Gate Valve?

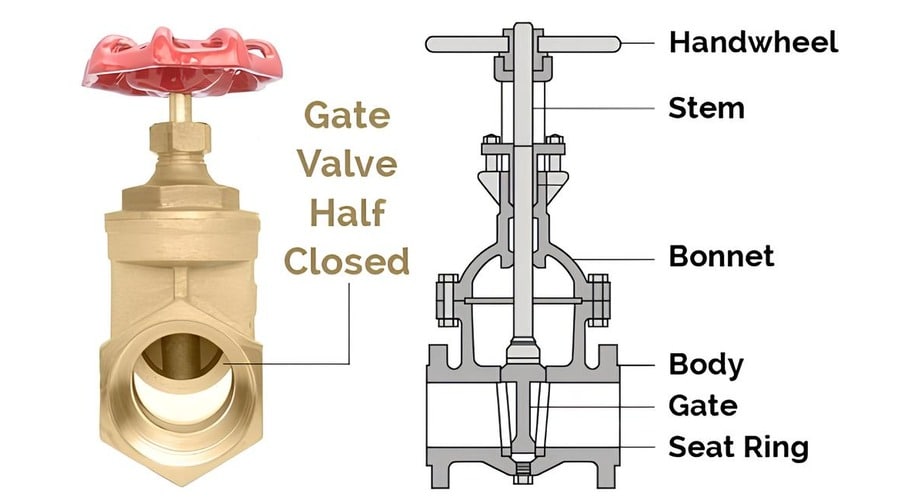

Figure 1. Gate valve

A gate valve is a kind of control valve that permits fluid flow through unobstructed or stops fluid flow. The most significant aspect of a gate valve is that it allows fluids to flow straight through without any obstruction. This means that there is a minimal pressure loss across the valve.

In contrast to butterfly valves, a gate valve’s clear bore also lets a pig pass through when cleaning pipes. However, quarter-turn valves move faster than gate valves, and they should only be used to open or close fully. You shouldn’t use them to control the flow.

One of the most popular valves is the gate valve because it is easy to use and has many applications. Gate valves have full-port ports, which means that the valve port size is the same as the length of the pipe that connects them. Full-bore gate valves enable fluid to move quickly through pipelines without obstruction or reduction in pressure. You can also use a cleaning rod to clean the line.

What Is a Ball Valve?

Figure 2. Ball valve

A ball valve controls the flow of gas or liquid. It uses a round ball with a hole inside it. The axis’s quarter-turn (90 degrees) determines if the medium can pass through or obstruct it.

These valves have an extended service life and maintain stable sealing performance throughout their lifespan, even when inactive. As a consequence, they are more widely used as shut-off valves than others, such as gate valves.

Specialized designs use ball valves as control valves. Few people use these applications because they cannot control the flow rate as accurately as other valve types. However, the valve also provides some benefits in this regard. A prime example is its ability to maintain a tight seal regardless of the presence of stained media. Check out our online ball valves and gate valves.

Gate Valve Vs. Ball Valve: Key Differences

In this blog, we will explain the working of both valves to clarify the distinction between the ball and gate valves.

Ball valve Vs. gate valve: working

Figure 3. The working mechanism of the ball valve

A ball valve employs a rotating ball with a bore and a stem. Rotate the ball using the stem-affixed handle to either open or close the valve. This valve, known as a quarter-turn valve, allows or blocks media passage with a 90° handle rotation. The handle to the pipe signifies an open valve, whereas a handle perpendicular to the pipe implies a closed valve.

A gate valve regulates the passage of the medium through a gate. A gate consists of a solid disk joined to the stem. The gate lowers to its initial position to close the valve after it has been raised to enable the valve to open.

A bonnet accompanies the valve and regulates the position of the gate through rotation. This “multi-turn valve” requires a 360° rotation to open or close fully.

Valve flow direction

A gate valve is the best choice for applications where flow is restricted in one direction. Additionally, gate valves work well when a lot of fluid needs to move quickly. Ball valves, on the other hand, work better when flow passes in both directions.

Ball valves are easier to operate than gate valves. This makes them a good option for situations that need frequent opening and closing of the valve.

Valve seal capacity

Gate valves close entirely, with the valve disk when shut, making them ideal for high-pressure scenarios that require a secure seal. On the other hand, ball valves have a small opening in the middle of the valve disc. Although a gate valve can open and close faster than them, too much pressure prevents it from locking firmly.

Valve design and construction

The advantages and disadvantages of gate and ball valves stem from their unique operation and design. Depending on your needs, one typically outperforms the other.

Ball valves are more suitable for handling liquids than gate valves, which are typically used for gases. A round gate allows or restricts fluid passage through gate valves, whereas a ball serves the same function in ball valves. Although both varieties of valves are versatile in their applications, they each possess unique advantages and disadvantages.

Although gate valves are less expensive and easier to repair than ball valves, they are not as robust. Conversely, ball valves are considerably more resilient and can withstand higher pressures despite being costlier and difficult to repair.

Ports

Its ports control the way a valve opens and closes. A gate valve has only two ports, which means it can work either way. Depending on its type and use, you can thread, join, or flange the holes in the gate valve.

But ball valves can have more than one port. Depending on the type of valve and its purpose, you can thread, join, or flange these holes. Three-hole ball valves allow different materials to flow in various directions. If a valve has holes, it’s essential to know its purpose and specific size.

Full-port valves have balls with holes the same size as the pipes they connect to. The hole in the ball valve’s ball with a lowered port is smaller than the pipe.

Applications

Both gate and ball valves are frequently used in industrial and residential settings. Marine and fire protection systems often employ ball valves. Ball valves do not suit food, drink, and medicine because they require difficult cleaning and can become contaminated.

Ball valves do not perform well because they require difficult cleaning, and slurry particles can cause damage to them. People use gate valves in hot, high-pressure places like power plants, mines, and water treatment facilities.

Gate valves are better for dense slurries because they are easier to maintain and clean. People predominantly install gate valves in applications that do not necessitate frequent shut-offs or in antiquated piping systems.

Sufficient water supply lines employ gate valves owing to the reduced flow restrictions and direct flow path they provide. People use ball valves more frequently in newly installed piping systems that require frequent shut-offs.

- Durability

Gate valves usually last longer than ball valves because they have some moving parts and are less likely to rust. Ball valves can develop leaks over time, but are easier to fix when needed.

Ultimately, the user’s wants and tastes dictate the type of valve to use. It would be best to have a valve that can handle a lot of wear and tear. A gate valve is a good choice. A ball valve might be a better option if you prioritize ease of repair.

- Maintenance

Ball valves have more durability than gate valves. We anticipate a higher demand for gate valve replacement and maintenance.

Ball valves need no maintenance. If not removed from service, it’s better to replace them rather than repair them. These valves are used in applications that involve high pressure and high cycle counts.

Globe Valve Vs. Ball Valve Vs Gate Valve

Globe valves, gate valves, and ball valves are the three primary types of valves. Each variant has distinct merits and demerits; the specific required valve depends on the intended use. This study will compare three popular valve types: the ball, gate, and globe valves.

People often use globe valves in applications that require precise control and regulation. They are suitable for controlling flow but can be more challenging to maintain and more expensive than other valve types.

Ball valves are ideal for situations that require a quick shut-off. People commonly use them in applications requiring a complete shut-off, such as gas pipelines. However, they can be more expensive and difficult to maintain than other valves.

Gate valves prove to be highly suitable for situations that require a fully open or closed valve. People often use them in water pipelines and other applications that require a total shut-off. However, operating gate valves can be more complex than operating other valves.

Are Ball Valves Better Than Gate Valves?

The professional engineering community holds differing opinions on whether they prefer gate or ball valves. Choosing the correct valve depends on the project’s requirements, as each type has pros and cons.

- Function

A quarter-turn valve, also known as a ball valve, controls the passage of water by utilizing a ball with a central aperture. The lever attaches to the ball to turn the valve on or off. By contrast, a gate valve is a linear apparatus utilized to control the passage of water through a gate. You must rotate a lever, an integral component of the gate, to operate the gate.

- Application

Ball valves perform better than gate valves in situations requiring a secure seal, such as gas or water lines. However, gate valves are more appropriate in conditions requiring a significant flow volume, such as wastewater lines. Additionally, ball valves are generally easier to operate than gate valves.

Speeds of closing and opening

A ball valve is better for quick opening and closing situations because it turns a quarter. The valve must rotate over 360 degrees to operate. It relies on these attributes. Both valves operate efficiently when constructed to carry out their specific functions.

From Tameson

Choosing Between the Gate Valve and Ball Valve

Before choosing between a ball valve and a gate valve, you may consider the following:

Ports: A gate valve typically has two ports, whereas a ball valve may have more than two.

Flow Capacity:

The stream capacity of a gate valve is usually higher than that of a ball valve because gate valves come in larger sizes.

Sealing: When comparing a ball valve to a gate valve, a ball valve features a tight cover that can completely shut off the flow. Because of this, ball valves work better in situations like natural gas, where a tight seal needs to last a long time.

Both the ball valve and gate valve are suitable for low-pressure situations. A gate valve, on the other hand, is better for high-pressure circumstances. The ball valve opens and closes quickly, which can cause a water hammer.

Cost: A gate valve with the same specs usually costs less than a ball valve. However, a ball valve tends to last longer and needs less maintenance, so in the long term, it may be cheaper.

Connection: A connection to the pipe is a significant aspect of both valves. To determine the best value for your needs, consider the advantages and disadvantages of both ball and gate valves. Evaluate all relevant factors before making a decision.

Conclusion

A crucial distinction lies between the ball valve and the gate valve. You can partially open ball valves b, ut only fully close or fully open gate valves to control flow. Various industries utilize gate valves and ball valves because of their dissimilar capabilities. People frequently use gate valves in industrial, mining, and massive water distribution systems.

Ball valves are widely used in various sectors, including the automotive industry, manufacturing facilities, and the food and beverage industries.

When picking valves for pipes or gas systems, consider cost, durability, and technical distinctions. Gate and ball valves perform comparable functions but provide varying degrees of control.

When comparing a ball valve and a gate valve, it is essential to consider the specific requirements of the application. Additionally, it is vital to pick a reliable ball valve manufacturer that can provide reliable products.