Which One’s Right for You?

Don’t Get Ballsy About Your Valves: Choose Brass or Bronze Confidently! Get together, plumbers and DIYers, to ditch the guesswork and improve your plumbing skills! Despite the bronze vs. brass ball valve battle raging, you should not be caught in the crossfire.

You have reached the correct location. We’ll be comparing brass and bronze ball valves in this matchup. We’ll also explore the significance of a brass ball valve manufacturer in making good-quality products.

Brass or Bronze: That is a typical question when looking for plumbing or industrial valves. Copper makes Brass valves, and bronze valves are made mostly of copper. Their unique qualities and traits make them good for various uses.

Is Brass and Bronze the same thing?

Many of us get confused: is brass the same thing as bronze? Bronze vs brass valves are not different but equal. Despite having different compositions, they are alloys with copper as the main component.

Meanwhile, the main constituents of bronze are copper and tin, and the main parts of brass are copper and zinc.

Composition and Key Differences:

Copper is the mandatory component of both brass and bronze ball valves. You must be wondering if brass and bronze are both the same thing. Bronze is copper with tin, aluminum, or silicon, while brass is mostly copper and zinc.

Copper vs bronze vs brass—these alloys have their unique characteristics. Brass is yellowish and made of copper and zinc, while bronze is reddish-brown and made of copper and tin.

You don’t have to worry about lead. When it comes to potable water, brass performs well, keeping you and your family hydrated and healthy. To tell if brass is lead-free, look for a light yellow color. Bronze is strong and doesn’t break easily. Water corrodes brass more easily than bronze, which is known for its durability.

What is the density of brass?

According to its composition, brass has a density ranging from 8.4 to 8.73 grams per cubic centimeter (g/cm3). Therefore, one cubic centimeter of brass might weigh between 8.4 and 8.73 grams.

There are a few elements that can affect the density of brass. Copper and zinc content material: Copper and zinc have a unique ratio that affects the density of the alloy.

Material with a higher copper content is generally denser. The density of certain types of brass, such as “leaded brass,” can be increased by incorporating a small amount of lead.

It is also possible for the manufacturing process to have a mild effect on the density of brass. You might want to consult its cloth datasheet or contact the manufacturer if you want a higher density for a specific brass form.

Let’s explore the significant characteristics of bronze valves vs brass valves.

What is Bronze Valve?

Bronze valves have a reputation for lasting a long time and resisting corrosion. They frequently choose them in hostile settings, such as those containing salt water. Particularly prized for their resilience to sea conditions, bronze ball valves are ideal for shipbuilding and offshore applications.

Bronze, one of the OG metal alloys, has existed since about 3500 BC. This copper and tin material has remained unchanged, proving its durability. Looking closely, you might spot small holes and rough surfaces, thanks to the casting process.

What are the effects of corrosion and abrasion?

Bronze is all about elevated flexibility, corrosion resistance, and affordability—the go-to for various applications, from flow direction control to safety relief and shut-off. And don’t worry about lead; we design lead-free bronze ball valves to meet the Clean Water Act’s requirements.

What is a Brass Valve?

Now, let’s talk brass. This metal alloy made its debut much later, around 500 BC. Brass, composed chiefly of copper and zinc, has many alloy variations, making it cool. Its flexibility and ease of working with it make it a favorite for casting, forging, heat extrusion, and cold drawing.

For cases where the valve requires easy machining, experts recommend brass valves. Commonly found in plumbing and heating systems, their corrosion resistance is less than bronze.

Like bronze, brass can hold its own against corrosion, but be cautious with high chlorine levels. Brass is safer for drinking water because it has less lead. Brass valves are also highly effective in natural gas pipelines.

Ball valves are available in bronze and brass, each with advantages and disadvantages. But which one should you choose? Let’s get right down to business.

- Bronze vs. Brass Valves: Applications

- The following programs and industries are ideal for bronze valves due to their unique properties:

- The petrochemical industry

- The marine industry

- Relief from safety hazards

- Control of flow course

- Shutting off the flow

- Flow-control brass valves offer the following unique benefits:

- Shutoffs for air and liquid

- Natural shutoff of gasoline

- Control of the flow course

- A potable water supply

Bronze Valve vs Brass Valve: Main Differences

Durability

Brass vs bronze valves are preferable to bronze valves for durability. Tougher, stronger, and more malleable. Bronze is the ideal metal to use in extremely salty and chlorinated environments.

Heat Endurance

Both of these alloys remain stable even at extremely high temperatures. The high melting point of bronze, an alloy of copper and tin, makes it a durable and versatile metal.

Malleability:

Can someone shape bronze? Heat and pressure can shape bronze, although the metal is less pliable than brass. You can work bronze, but it’s not as pliable as metals like brass, so you might find it tough to form the desired shape.

Manufacturing Technologies:

In manufacturing, brass offers a variety of methods, including casting, forging, hot extrusion, and cold drawing. This versatility means less porosity and a smoother surface. Conversely, Bronze relies mostly on casting, resulting in a rougher and jagged finish.

Metal Mash

The metal mash, or the interaction of the valve with the media, is crucial. Brass contains 2–3% lead, while bronze goes significantly higher with 5% or more. This extra oomph in bronze can scatter more metal in the medium. So, your best bet for potable water, meeting the Clean Water Clean Water Act’s lead requirements, is brass valves.

Media and Uses

This one’s all about picking the right alloy for the job. Brass is king for plumbing and potable water applications—also a hit in the oil and natural gas industries. Bronze valves are corrosion-resistant, making them popular in maritime and industrial sectors. Be cautious with the lead-in bronze valves, and go for the lead-free option if needed.

Corrosion Resistance

In the corrosion resistance showdown, brass takes the lead for hydrothermal sanitary applications. It can handle most things but might get a bit stressed with high chlorine. On the other hand, bronze is no pushover regarding dezincification corrosion and overall resistance.

Conductivity:

Need to manipulate electric-powered currents? Conductivity brass valves come to the rescue in electricity undergrowth and chemical factories. Bronze prefers to paste to the liquid flow.

In addition to the brass gate valves, the pipes are welded to the gate valves to enhance their strength. Do you have an online pipe adjustment system on your website? For clean disc and valve function replacements, bronze is the best option.

Melting Point

The melting point is where things heat (literally). Bronze melts at 1590°F, while brass takes it to 1710°F. Brass has a lower melting point than bronze in degrees Fahrenheit. Bronze valves are better for high-temperature applications as they don’t deform or lose their structure.

Machinability

Brass is the darling of the valve industry because of its ease of machining, high cutting speeds, and lower production costs. Conversely, bronze isn’t as adaptable to mechanized machinery, especially those made by casting.

Color and Appearance:

There is a visible color difference between brass and bronze

Brass is yellow-gold and can make plumbing fixtures and valves look nice. Bronze, however, has a reddish-brown hue.

A brass heat color chart shows how brass changes color when heated to different temperatures. It starts as light yellow and becomes a darker gold as it gets hotter. Brass can change color with temperature, so it has many uses in metallurgy.

Composition

Brass is a combination of copper and zinc. Bronze is a mixture of tin, aluminum, beryllium, manganese, silicon, lead, and other elements. Each alloy type has its unique properties, so choose wisely.

Ductility

Composition, microstructure, heat treatment, and chemical composition all affect ductility. The ductility of bronze is generally greater than that of brass, however. This is because bronze has a lower melting point and a higher carbon content than brass.

Moreover, bronze is much less likely to undergo segment changes than brass, which makes it more ductile. The difference in ductility between bronze and brass is evident in numerous examples. Among other things, bronze is frequently used to manufacture pipes and tubing due to its greater ductility and ability to be easily shaped

Price Comparison:

Is brass more expensive than copper?

Regarding cost, brass valves are less expensive than bronze valves. Because of its low cost, brass is a popular material for household plumbing and irrigation systems.

What is brass worth? The more affordable zinc makes brass three to four times cheaper than bronze. Plus, brass’s malleability and ease of machining keep those finishing costs down.

How do you tell the difference between brass and bronze?

When was brass first used? Long ago, people used brass, starting around 3000 BC in Mesopotamia and the Indus Valley.

How to tell if brass is lead-free: Examine any certifications or documentation available to determine whether brass is lead-free. Lead-free brass frequently has this labeled designation.

Brass is generally safe to drink. However, it may contain trace quantities of lead. If you have doubts, is brass safe to drink from?

Ball valve suppliers and brass fitting suppliers

Ball valve and brass fitting suppliers are important in various industries, providing essential fluid control and plumbing parts.

Are Brass Valves Better Than Bronze Valves?

The plumbing arena boasts many valiant warriors, each with strengths and weaknesses. With bronze, you will be tough as nails and able to take on tough environments like a pro in the petrochemical industry.

In the battle of brass vs bronze, brass valves often come out on top regarding performance and durability. Brass tends to have the upper hand but has a kryptonite – high chlorine levels. Other than that, it’s a corrosion-resistant champ with minimal lead levels and excellent durability.

Need a few turns? Bronze is the metal of choice for forming pipes and tubes effortlessly. The path of brass must be conventional, even though it is strong.

Industrial gladiator: For severe environments, warm water, and long-lasting performance, Bronze is your go-to.

Brass is your budget-friendly choice for smooth water control and shut-off. Take on the valve aisle like a pro! Have trouble deciding? Here’s a bonus tip: Talk to a plumber. You can count on them to locate the right valve for your needs, ensuring a leak-free, worry-free future. Now construct your plumbing empire, one flawlessly selected valve at a time!

How to Choose Between Brass Valves and Bronze Valves

So, which one should you pick for your specific application? It all concerns your media, purpose, environment, and desired use. Brass valves shine in various applications, from air and liquid shut-off to natural gas. High-performance situations and maritime use prefer bronze valves because they resist corrosion.

Are Brass Valves Better Than Bronze Valves?

In the battle of brass vs. bronze, brass valves often come out on top regarding performance and durability. Brass tends to have the upper hand but has a kryptonite – high chlorine levels. Other than that, it’s a corrosion-resistant champ with minimal lead levels and excellent durability.

How to Choose Between Brass Valves and Bronze Valves

So, which one should you pick for your specific application? It all concerns your media, purpose, environment, and desired use. Brass valves shine in various applications, from air and liquid shut-off to natural gas. High-performance situations and maritime use prefer bronze valves because they resist corrosion.

Ball Valves: Brass versus Bronze

Both alloys have their place in different fields and applications in the showdown between brass and bronze valves. Brass may have a slight edge in durability and performance, but choosing between them depends on your needs.

Remember to contact an experienced industrial valve manufacturer for all your valve needs. They will guide you to the best possible candidate for the position. You have understood the distinctions between brass and bronze ball valves. Let’s give this some serious consideration.

The Role of a Brass Ball Valve Manufacturer

The market for brass ball valve manufacturers must deliver reliable and effective goods.

It would help if you only acquired valves from renowned manufacturers for your project.

Selecting a brass ball valve manufacturer that follows industry standards is important to ensure durability. Additionally, strict quality control procedures ensure the valves’ functionality.

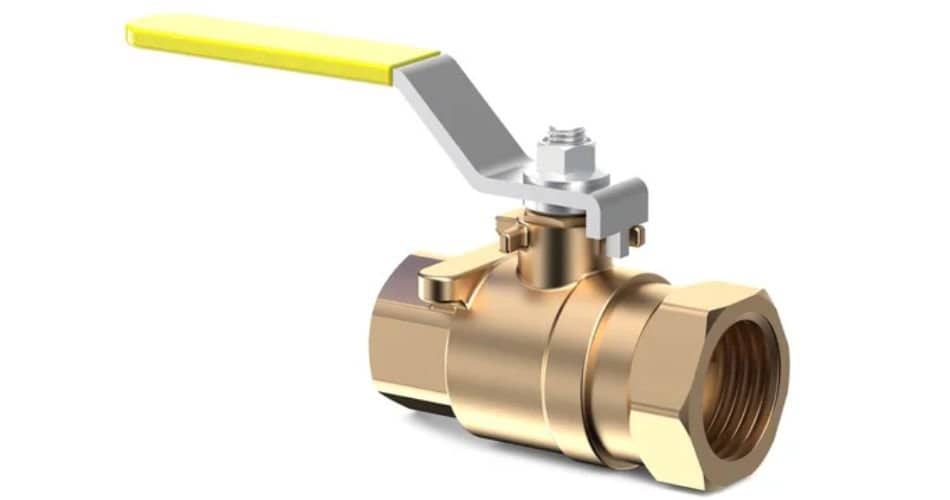

Because ball valves are versatile and long-lasting, people often use them to control the flow of liquids and gases. These valves seal oil and gas pipelines and water treatment facilities when there is a need for a strong seal.

A ball valve has a rotating, hollow ball that controls how much fluid may pass through the opening.

The protection of the Flow Control Valve is a huge difference:

Most shut-off valve and disc positions could be changed online without removing the whole valve from the pipeline with brass gate valve protection. In this process, the valve and pipe are welded together. It fits perfectly. There is, of course, a lot more to the difference between a Brass gate valve and a Brass globe valve.

Brass Fitting:

Plumbers commonly use brass fittings because they offer toughness and resist rusting easily. This is because brass is a strong and flexible material. Brass is a popular material for these components because of its strength and malleability.

Plumbing and fluid transfer fittings are only some of the many products brass fitting suppliers stock and offer. Brass fitting makers and ball valve suppliers work hard to ensure their products are top-notch. We extensively test every component to guarantee durability, endurance, and dependability.

They’re a safe selection for many applications because of the diversity of customization possibilities accessible.

Conclusion:

Deciding whether brass or bronze valves are better for your needs is up to you. Brass valves might be the way to save expenses and speed up production without losing quality. When robustness, lifespan, and resistance to corrosion are of the utmost significance, bronze valves are the material of choice. If you get your valves from a reputable provider of brass ball valves manufacturer, you can rest assured that they will function as designed.