Ball valves are widely used for fluid control. A disc resembling a ball controls liquid flow inside the valve. Their versatile nature makes them best suited for industrial use.

Ball valves come in many structures and sizes. They have numerous applications. Ball valves are more common among commercial users. It is because of their inexpensive and reliable nature. The 3-way motorized ball valve is one such product. Here is a detailed article on 3-way motorized ball valves.

In the bustling landscape of fluid control systems, the humble yet potent 3-way motorized ball valve often takes a backseat amidst its more conventional counterparts. Yet, as one ventures into the nuances of fluid dynamics and control systems, the pivotal role of this unique valve variant comes to the forefront. But what exactly is a 3-way motorized ball valve, and why is it integral in advanced fluid control setups?

A 3-way motorized ball valve is essentially a ball valve with three ports and an electric motor to automate the valve operation, a convergence of manual control and automated precision. Unveiling the curtains of its operational principle is a journey through its well-orchestrated design and exploring the realm of automated fluid control.

Why is the 3-Way Configuration Significant?

The 3-way motorized ball valve’s essence lies in its three-port design, which acts as a gateway for fluid control in multidirectional pathways.

- Diverter or Mixer: With three ports, these valves can either divert the flow from one inlet to two different outlets or mix flows from two inlets to a single outlet.

- Fluid Control Mastery: They allow for a more complex control over fluid flow, which is crucial in applications like heating systems, industrial processing, and HVAC systems.

The versatility of the 3-way configuration is the cornerstone of its widespread utilization in various industrial and residential applications.

Unpacking the Motorization of the Valve

The 3-way ball valve’s motorized facet harnesses the power of automation, augmenting its functionality, reducing manual intervention, and enhancing precision.

- Electric Motor: The valve has an electric motor that automates the valve’s opening, closing, and positioning.

- Remote Operation: Motorization allows remote operation and integration into automated systems for seamless fluid control.

- Precision Control: The motor ensures the valve’s precise positioning, which is crucial for accurate fluid flow control.

The amalgamation of mechanical prowess and electronic control translates to higher operational efficiency and ease of control.

Are 3-Way Motorized Ball Valves the Right Choice?

The decision to opt for a 3-way motorized ball valve depends on the fluid control system’s specific needs.

- Automation Requirement: If automation and remote control are priorities, motorizing the valve is a logical step.

- Flow Control Complexity: For systems requiring multidirectional flow control, the 3-way configuration is advantageous.

3-Way Motorized Ball Valve Details:

A three-way motorized ball valve is one type of ball valve. As the name indicates, it has three ports controlling fluids for three locations. The use of an electric motor actuates motorized ball valves.

The motor’s function is to open or close the valve. It rotates the ball or disc inside the valve, which causes the start or stop of flow. We mainly install them where we can control the flow with a remote. They give precise flow control, so they are best for use in industries. Motorized ball valves are available in many different shapes and sizes.

| Specifications. Product: 3-way Electric motorized ball valve. Material: Brass. Voltage: 24V, 220V, 230V, 50/60 Hz. Size: 1/2-1-1/4 Pressure: PN16-PN20 Power: 60W. Mode: Electric, Manual, along with a position indicator. Media: Water.Connection: Threaded BSP, NPT. Medium Temperature: 15°C to +95°C Applications: Household usage. |

Buy Premium Quality 3-Way Motorized Ball Valve here.

Types of Motorized Ball Valves:

Besides 3-way, motorized ball valves do have other types. They serve different functions. It makes them applicable to many other locations.

- 2-way Motorized Ball Valve: This motorized ball valve has two ports. It allows fluids to stop across two ports. It usually works like a shut-off valve or a regulatory valve.

| Specifications. Product: 2-Way Electric Control Ball Valve. Material: Brass. Connection: Threaded. Torque: 2Nm. Size: 1/4, 3/8, 1/2, Pressure: 1.0 MPa Working Temperature: 2-100°C |

- 4-Way Motorized Ball Valves contain four openings and control fluid flow across four ports. They can let the fluid pass from one port to the other. We can also stop the liquid flow from a particular port in this type of valve.

| Specifications. Product: Pneumatic Actuated 4-way Ball Valve. Connection: Threaded. Size: 1/2-3, DN15 to 80. Pressure: 1000 Psi. Working Temperature: Normal Temperature. Applications: Heavy-duty industrial usage, commercial usage. |

- Multi-port Motorized Ball Valves: Multi-port valves are generally standard for industrial use. They have more than four openings to handle many streams. They can redirect or stop the flow of a port. They also regulate or shut off the fluid supply.

3-way motorized ball valves are available in many different materials. Each material has other properties. Some of the best-selling motorized ball valve materials are below.

- 3-Way Brass Motorized Ball Valves: The valves made of Brass are easy to operate and install. Brass is softer than other metals. Thus, it makes sealing easier. Brass motorized ball valves are best for water operation. They offer a wide range of corrosion resistance. Brass is an economical option and lasts longer.

- 3-Way Stainless Steel Motorized Ball Valves: Stainless Steel applies well to houses and commercial uses. It has a durable and versatile nature. Stainless steel can endure a good range of temperature and pressure changes. 3-Way stainless steel motorized ball valves are corrosion-resistant. They cost a little more than brass valves.

- 3-Way PVC Motorized Ball Valves: PVC ball valves are versatile and reliable. They are highly resistant to high temperatures and pressure. They can be installed quickly without the help of a plumber. PVC motorized ball valves cost less and require less maintenance. Yet, saltwater exposure can cause corrosion in PVC valves.

Functions of a 3-Way Motorized Ball Valve:

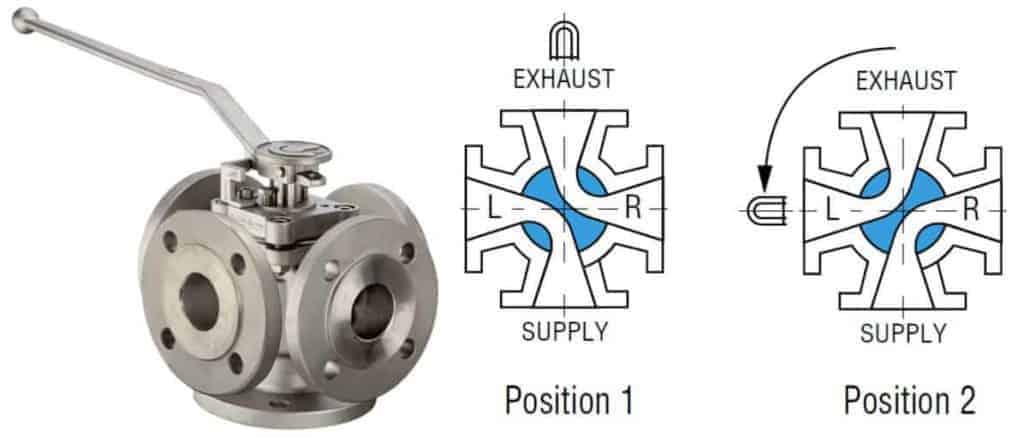

A 3-way motorized ball valve contains three openings. One is an inlet; the other is an outlet; the third can be either. It can also be an exhaust port that releases the pressure from within the valve. The inlet valves bring liquids or gases into the valve. At the same time, the outlet takes fluids out.

The primary function of a 3-way motorized ball valve is to control liquid flow from a pipeline. It can open or close the fluid flow. The exhaust port helps remove excess pressure from the valve. The valve can also divert the flow from one outlet to the other.

The 3-way motorized ball valves perform another unique function. They can cut off the water supply from one section. Fluids can flow from one chamber to another without any disturbance. It is very beneficial if someone has to do maintenance work. 3-way motorized ball valves save from the problem of a complete shut-off. Instead, the flow from the defective side can be shut. These functions make the 3-way valve a favorite product.

Working of a 3-Way Motorized Ball Valve:

A 3-way motorized ball valve has an electric motor that rotates the ball within the valve body. The ball has a hole in the center. This aligns with the Inlet and outlet ports. In an open position, it lets the fluid pass across. While in a closed position, it cuts off the supply.

The motor either contains a controller or a remote that sends a signal to open or close the valve. A stem lies in the center of the valve that connects the motor and the ball. The branch also rotates when the motor rotates, causing the ball’s station to. It then changes the aligning position of the valve, causing it to open or close.

Water flows from the Inlet and outlet if the openings are aligned. The ball blocks the fluids if they are not aligned with the valve body. A sealing surface lies on the ball. It tightly closes the valve when in the closed position, preventing leaks.

The working mechanism of a 3-way motorized ball valve is simple yet effective. It is a highly reliable product. The versatile nature of this valve makes it best suited for piping systems.

Applications of 3-Way Motorized Ball Valve:

3-Way Motorized ball valves apply to water, oil, and gas operations. Industries use them primarily. They can undergo relatively high heat and steam conditions in industries. Motorized ball valves are also a household product. Commercially, they are of great importance.

- 3-way Brass Motorized ball valves are corrosion-resistant and heat-resistant. Brass has distinct properties that make it best suited for industries. They are widely used in HVAC and other manufacturing.

- PVC valves are exceptional for use in pipeline systems. They are also suitable for irrigation and commercial pipelines and can endure pressure and temperature changes.

- Industries use Motorized ball valves to carry out chemical reactions. They can stop, divert, or control the fluids coming from pipelines.

- Water treatment plants also use 3-way motorized ball valves. They control the flow of water towards the distribution system.

- In reaction chambers, these valves regulate and control the flow of chemicals.

- Motorized ball valves can also transport oil and gas. They can easily handle such fluids.

- Irrigation systems use 3-way motorized ball valves to distribute water through multiple streams.

- Fire sprinklers and water heaters also use 3-way motorized ball valves to manage the flow.

- HVAC Systems: These valves facilitate precise control over fluid flow and are instrumental in heating, ventilation, and air conditioning systems.

Its application is a testimony to its robustness and operational flexibility that caters to many control requirements.

How to Install a 3-Way Motorized Ball Valve?

Installation of a 3-way motorized ball valve requires plumbing knowledge. As it has an electric motor, wiring is an essential element. The general steps for installation are as follows.

- The process begins with shutting off the water supply. You can turn it off if you have a shut-off valve at a particular location. This is essential to stop fluid flow.

- Next, select the correct location where you have to mount the valve. Choosing a side where the electricity supply is easy to access is better.

- Cut the pipe from a specific location using a pipe cutter. You can mark the exact space and cut it where the valve will be installed.

- Place the 3-way motorized ball valve and connect it to the outlet pipes. Turn on the water supply to ensure there is no leakage.

- The next step is to connect the electric wires to the valve’s motor. Reading and following the manufacturer’s instructions is essential, as every product can have different wiring instructions.

- Generally, the wire from the main supply must connect to the motor’s terminal side. Sometimes, an extra wire is tied for the signals or controls.

- If the valve has a manual operation, check its functioning manually. Otherwise, test the valve using the remote control. Follow the instructions on the package.

- Now, turn the water supply on, which was cut at the beginning of the process.

The process is not very tricky, but if you are unfamiliar with wiring, it’s better to call a plumber.

From The Control Room by ControlTrends

Conclusion:

The 3-way motorized ball valve is not just a component; it’s a testament to the technological advancements in fluid control systems. Its ability to blend the mechanical rigors of a ball valve with the precision of motorized control while offering multidirectional flow control sets it apart as a valued asset in modern fluid control systems. Exploring its potential is akin to venturing into enhanced control, efficiency, and operational ease.

3-way Motorized ball valves are multi-purpose valves that are highly applicable in every industry. The applications, types, and workings are discussed so you know the product before purchasing it. You can also make a self-buy guide before choosing the product.

Plumberstar has a variety of excellent-quality valves. You can purchase a premium-quality 3-way motorized ball valve here.