Introduction:

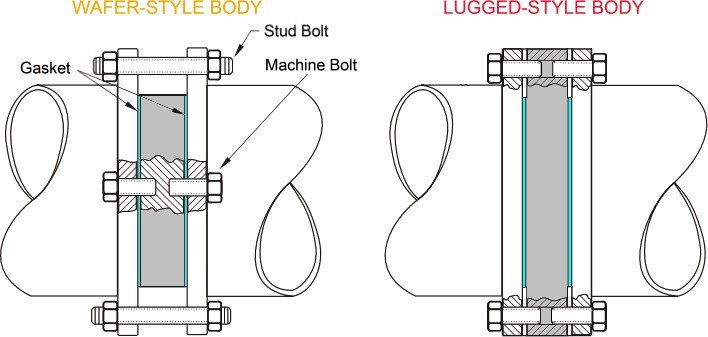

There are two types of butterfly valves: wafer butterfly valves and lug butterfly valves. Wafer butterfly valves are connected with two flanges and are softer in weight. As compared to the lug butterfly valve, they are more expensive. A wafer butterfly valve is best for those applications where space is less and the profile is low.

On the other hand, a lug-style butterfly valve is connected with a threaded valve body. This type of valve is easy to install and remove for maintenance purposes. Moreover, lug-style butterfly valves serve better in high-pressure applications than wafer butterfly valves. Both valves significantly differ in working, structure, cost, installation, operation, and maintenance. Therefore, the pendant decision is based on your needs when selecting one between the wafer and lug-style butterfly valve. This blog will be an elaborative guide about wafer and lug-style valves.

What Is A Wafer-Style Butterfly Valve?

Wafer-style butterfly valve that is connected with two flanges. Due to such design, they are softer and cheaper than the other butterfly valves. They usually operate under low pressure.

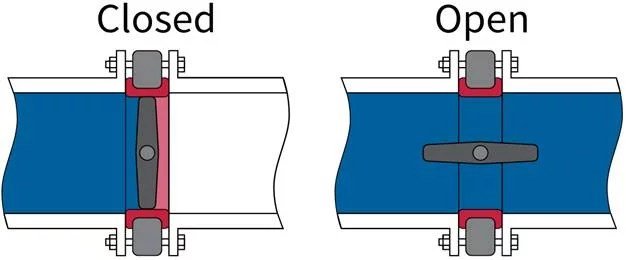

Stainless steel, cast iron, and plastic are the most common materials for wafer butterfly valves. The choice of material shall depend on your specific application requirements. This kind of valve consists of a disk popularly known as a butterfly valve that revolves around the central stem on and off the valve.

It means that the flow of gases and fluids can easily pass through the valve when the disc is open. A wafer butterfly valve will be best in applications with less space and low profile.

Please read our blog, Ultimate Guide to Butterfly Valve Types.

What Is A Lug Butterfly Valve?

A lug-style butterfly valve refers to a butterfly valve with threaded inserts in the valve body. Lug-style butterfly valves differ significantly in structure and installation from the wafer style.

The threaded insert on the lug-style butterfly valve aids in locking to a system without more nuts and bolts. These valves are easy to deal with and remove during maintenance applications. This is the best valve type for high-pressure applications due to the thickness of the body.

Lug-style butterfly valves are made of rigid and robust material. The significant uses of lug-style butterfly valves include industrial applications such as power generation and oil and gas. They are used to process chemicals where high pressure is usually applied.

Differences between Wafer Butterfly Valve and Lug Butterfly Valve

Any valve plays a vital role in the opening and closing of the piping system. Many types of valves play a significant role in industrial applications according to their major differences. There are some differences between the wafer and the lug-style butterfly valve, as follows.

· Working Differences:

Some significant operating differences exist between the wafer and the lug-style butterfly valve. The wafer butterfly valves are brighter and more solid, thus becoming the best option for minor pipelines with minimal space. Due to their simplicity, wafer butterfly valves are easily installed and maintained.

However, lug-style valves are more stable and better for more extensive pipelines or high-pressure applications. The lug-style butterfly valve provides extra support and controls movement under pressure.

Lug butterfly valves contain threaded inserts that allow them to lock onto the pipeline. The choice of a wafer butterfly or a style butterfly valve depends on your requirements and includes factors such as pipeline pressure, flow rate, and pipe size.

· Structure Difference:

The second difference between butterfly and lug-style butterfly valves refers to structural differences. The wafer butterfly valves are typically more solid due to the disc-shaped body and tight seal between the pipe flanges. This kind of valve needs low pressure to operate. They may be speedy and easy to use at coming pipelines as they come in standard size.

Compared to material linking and connection type, their solidness is not as good as lug butterfly valves. Lug-type butterfly valves have two main parts: a body and a disc. The body part connects to pipelines through bolts and nuts, while the disc helps control the flow of liquids or gases.

Such types of valves are suitable for high-pressure applications. This is why they possess an excellent resistance design and strength. However, they offer long-time installation and many more material options than butterfly valves.

· Cost Differences:

Wafer butterfly valves cost less than lug-style butterfly valves. Wafer butterfly valves have four holes, which help to pipe flanges for applications. Wafer butterfly valves are usually made of stainless steel, cast iron, and plastic.

Lugged butterfly valves have a cost that is more effective than wafer butterfly valves. Due to the higher price, they offer a solid connection to the pipeline. Usually, this type of valve can be most challenging to install and maintain. The lug-style butterfly valve is made of metals, such as steel or cast iron.

· Installation Differences:

Wafer butterfly valves are brighter and less expensive than their lug stand parts. Placed between pipe flanges, these valves also use a rubber or EPDM seat to form a solid seal.

Conversely, Lugged butterfly valves are usually made from flexible iron or steel and feature threaded lugs on their flanges for screw links. This design makes them suitable for end-of-line facility applications.

· Operation Differences:

Although wafer butterfly valves are connected with two piping flanges, they do not have feature connection lugs. This type of valve can fix the flange standards used in many industrial applications due to rubber and EPDM valve seats. This valve can work electrically and pneumatically for extra suitability and dependability.

Lug-style butterfly valves have feature-threaded lugs outside the valve. These lugs attach to piping flanges with the help of locked connections. This design helps one side of the piping system to divide without affecting the other.

· Maintenance Difference;

Wafer butterfly valves contain four holes that help with the pipeline related. They bolt between two flanges within the pipework. They have a rubber or an EPDM valve seat if an effective seal between them and their construction.

Lugged butterfly valves are made with metal such as cast iron or steel. Their feature threaded selected lugs are situated on their flanges for bolt relations. Lugged butterfly valves are usually used in high-pressure industrial applications and can work using electric or pneumatic actuation.

Conclusion

Both butterfly valves, wafers, and lug-style butterfly valves help control the fluid flow in the piping system. Wafer butterfly valves are solid and brighter, which is best for small pipes with limited space. They can be easy to install and maintain but are less secure than a lug butterfly valve. Lug butterfly valves are more stable and robust for large piping systems and high-pressure applications. This type of valve is more complex and expensive than wafer butterfly valves.

A style butterfly valve is the best choice for the fluid control solution. Before choosing between a wafer and a lug butterfly valve, you must consider many factors, including pressure, temperature, size, and installation and maintenance requirements.