Description

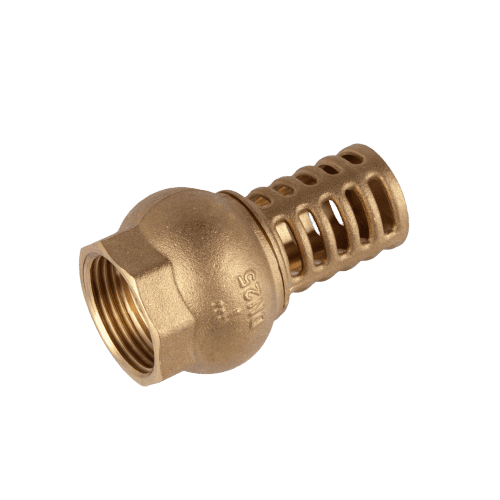

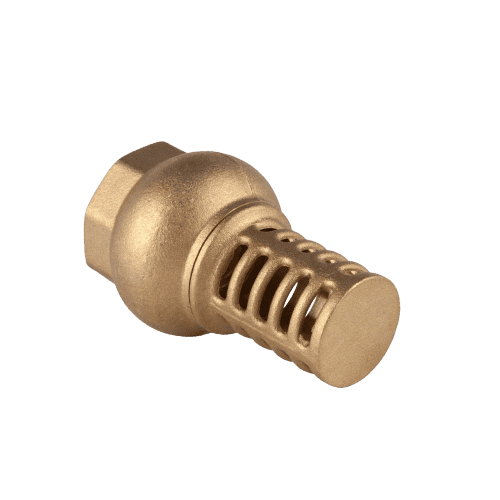

Water Brass Foot Valve

JX-0757

- Brass Air Vent

- Material: Brass

- Type: Foot Valve

- To fit an existing pump, allow the hose to be dropped into the water storage.

- Size:1/2″-2″

- Maintaining the foot valve below the water’s surface ensures the floating debris does not enter the pump.

- The foot check valve is suitable for suction lines on top-offtake tanks (where an anti-siphon valve is absent)—brass valve body, with NBR, sealing disc.

These foot valves are often used in dispensing pump systems, particularly with Centrifugal pumps, to prevent the pump from de-priming during rest. Suitable for use with water, oil, diesel, and many other none toxic acid-free fluids.Specifications:

– Size: 1″, 5/4″ (1 1/4″), 6/4″ (1 1/2″) or 2″;

– Body and strainer in brass;

– Strainer washer in fiber;

– Plate in brass;

– Washer in NBR;

– Minimum and maximum working temperatures: 0 – 90 ℃. - To protect piping materials and systems from air (oxygen) corrosion.

- To prevent water splashing at the faucet due to the existence of air.

- To prevent noise from the air ingress into cold/hot water supply systems, air conditioning systems, and other systems.

- For the smooth startup and stable operation of water supply and other systems/devices through air discharge at the initial water conveyance.

What is a foot valve?

This foot valve holds the prime in the pump while filtering large debris from lakes, wells, ponds, etc. Long-lasting, spring-loaded foot valves are manufactured with high-quality brass. Features include a perforated steel screen strainer, poppet with Buna-NO-ring, stem guide, and wide channel for maximum flow.

A brass Foot Valve is an important part of your plumbing system. It can help regulate water flow in your home, whether you’re using the sink, toilet, or dishwasher. When it comes time to replace or repair a brass foot valve, you must know how they function and what replacements are available on the market today.

The brass Foot Valve is located at the bottom of your plumbing system and regulates water flow. When you turn on the faucet, the valve opens, allowing water to flow into the pipes. Once the faucet is turned off, the valve closes and stops the water flow. This helps to keep your home’s plumbing system running smoothly and prevents flooding or leaks.

If you’re looking to replace a brass foot valve in your home, a few different options are available today. You can choose from manual or automatic valves, depending on your needs. Manual valves require you to open and close them, while automatic valves do it automatically. You can also choose between straight-pattern or angle-pattern valves, depending on the configuration of your pipes.

When it comes time to replace or repair a brass foot valve in your home, choose a valve compatible with your plumbing system. There are a variety of valves available on the market today, so be sure to do your research before making a purchase. With the suitable valve, you can keep your plumbing system running smoothly for years.

Design: How it Works

Design: How it Works is an in-depth look at the mechanics of a particular product type, in this case, the Water Brass Foot Valve. This product controls water flow and provides a secure seal for pipes that transport water. It helps prevent backflow and contamination, making it an essential component of any water system. By understanding how these valves work, designers can determine their suitability for a particular situation.

The Water Brass Foot Valve utilizes two main components: a valve body and a foot disc. The valve body is typically constructed from brass or stainless steel, while the foot disc may be rubber or similar. When pressure is applied to the foot disc by incoming water, it forces open the valve’s passageway allowing fluid to flow through it.

Benefits: Why Use It?

Water brass foot valves are a valuable tool for controlling the flow of water systems in various environments. These valves can offer significant benefits over traditional models, whether in an industrial setting, residential application, or commercial operation. Users can enjoy improved performance, greater energy efficiency, and cost savings over time by utilizing the right valve and installation methods. Take a closer look at why you should use water brass foot valves.

First and foremost, these valves are designed to withstand extreme pressure levels while providing superior performance compared to plastic or rubber versions. This makes them ideal for heavier hydraulic applications where high-pressure systems require reliable control that is not susceptible to leakage from wear and tear. Additionally, these devices feature simple construction, making them easier to install than more complex models.

Materials: What is it Made Of?

A Water Brass Foot Valve is an essential plumbing hardware used to control water flow in a pipe. It is important in preventing reverse flow and maintaining pressure within system pipes. This valve is typically made of two main materials: brass and rubber.

Brass has been used for centuries as a durable material, making it perfect for foot valves. It’s resistant to corrosion when exposed to water so the valve will last for years without damage. Rubber seals are also used inside the valve, ensuring a tight seal between the brass body and parts that attach it to other pipes or fixtures. The rubber material helps ensure no leaks occur while allowing easy movement of air bubbles through the system.

Sizing Considerations for Water Brass Foot Valves

When selecting a water brass foot valve, it’s important to consider the size of the valve and what application it is being used for. The size of the valve will determine how well it can handle the pressure and flow rate needs of a particular system. It is important always to select a valve larger than the required pipe size to reduce stress on the piping system.

The right size is also determined by considering factors such as water pressure and velocity and other variables like temperature, sediment content, and pH levels. If too small of a valve is used, there can be an increase in noise levels or even possible damage to the valves due to over-pressurization.