Description

|

Brass Underfloor Heating Manifold With Ball Valve

The integrated ball valve enables fast on-off control of each branch circuit. It is used to collect and shunt the hot water delivered by a boiler or a heat pump in a radiant floor heating system. By adjusting the opening degree of each branch ball valve with flow control. The flow is accurately distributed to each floor heating circuit pipeline, ensuring that the indoor temperature in different areas meets the design requirements.

|

|

|

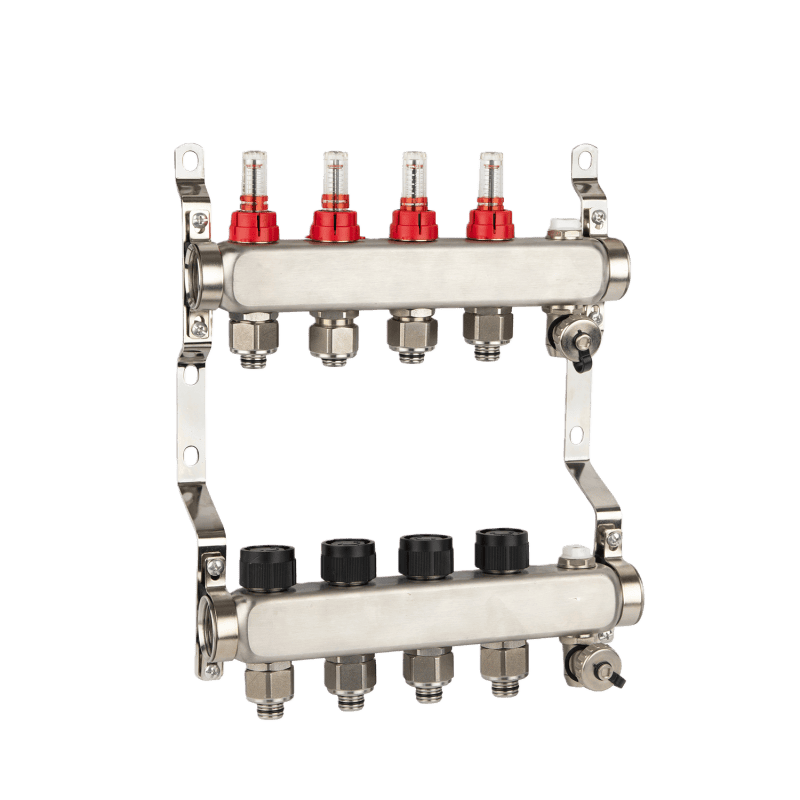

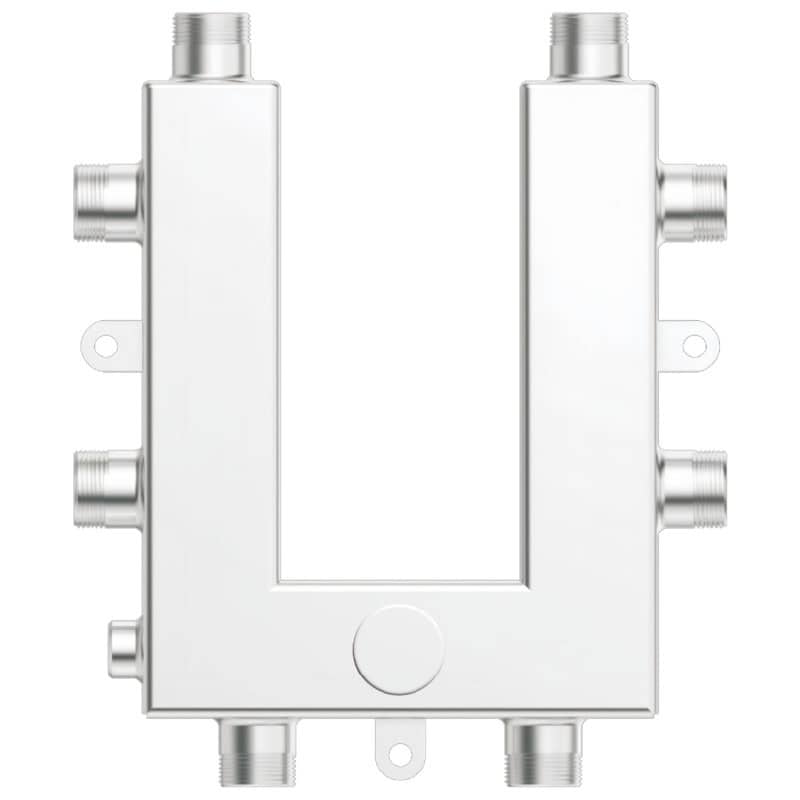

Stainless Steel Distribution Manifold

The stainless steel distribution manifold can work with different fluids and in complex conditions. It is used in heating, water supply, and industrial fluid systems to split or combine the main flow of fluid. It sends the right amount to each branch pipe and makes it easy to control and adjust the flow. And facilitate individual control, flow regulation, and maintenance of each branch.

|

|

|

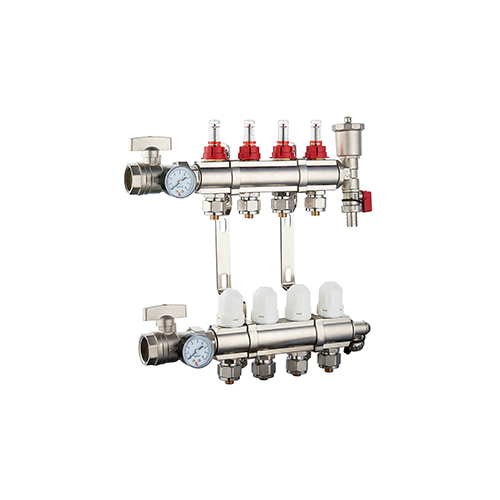

Heating Distributor

The Heating Distributor is the core fluid distribution and control device in the heating system. It adapts to the hot water medium and working environment of the heating system. It is used to collect the hot water from the boiler, heat pump, and other heat source equipment and distribute it evenly to each heating branch indoors. At the same time, it can accurately control the hot water flow of each branch through the matching valve or flow regulator.

|

|

Steel Boiler Manifold

Garden Hose 2-Way Splitter is a garden water supply accessory installed at the outdoor faucet or faucet interface. Its function is to divide a single inlet into two independent outlets. Each outlet is typically equipped with an independent switch to control the water flow separately. It is primarily used to meet the multi-channel water supply needs of gardens, courtyards, and other outdoor areas.

|

|

|

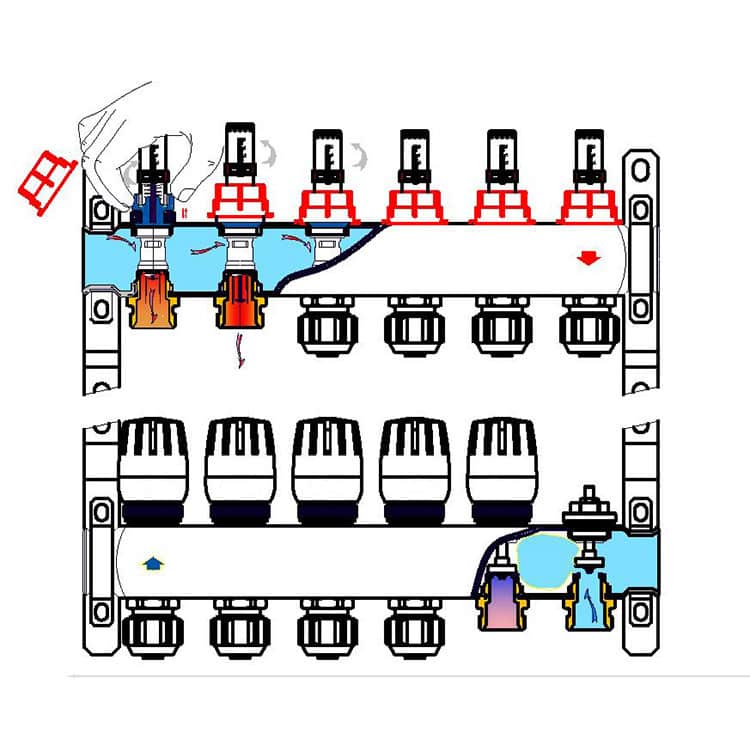

Hydraulic Balance Manifold

The Hydraulic Balance Manifold is a core regulating device specially designed for a fluid system. It is usually composed of the main pipe body, multi-branch interface, flow balance valve, and monitoring component. Stainless steel or brass is mostly selected to adapt to the working environment of the heating and water supply system. Its core function is to realize the hydraulic balance of each branch in the system and solve the problem of excessive or too small flow in some areas caused by uneven fluid distribution.

|

|

Annular Hydraulic Distributor

An Annular Hydraulic Distributor is a fluid distribution and regulation device with an annular structure design. The annular structure can realize a 360° uniform flow distribution of fluid, and adapt to complex pipeline layouts. It sends water or other fluids from the main pipe to each branch quickly and evenly in heating, water supply, and industrial systems. The flow and pressure of each branch can be controlled accurately using matching adjustment parts.

|