FAQs of Distribution Manifold

1. Is the Distribution manifold suitable for residential and large-scale commercial construction projects?

Yes! Plumberstar’s Distribution Manifolds are fully suitable for residential and large-scale commercial building projects.

1. Wide range of product applications: Plumberstar can customize solutions for customers. These solutions can be used for piping systems and radiant heating circuit manifolds. They can also be used in PEX floor heating projects. These projects often occur in residential and commercial buildings.

2. Clear customer groups: 80% of Plumberstar’s customer groups are wholesalers, construction companies, shopping centers, etc. This can prove that our products are often used in large-scale commercial projects. We have rich experience.

3. Strong production and supply capacity: The factory can ship about 20 containers every month. We have the ability to meet the huge order volume requirements of large distributors and major construction projects. Ensure the stability of the supply chain.

2. Can you manufacture Distribution manifolds with a custom number of loops?

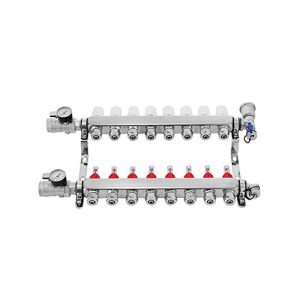

Plumberstar can customize the number of circuits for the Distribution Manifold.

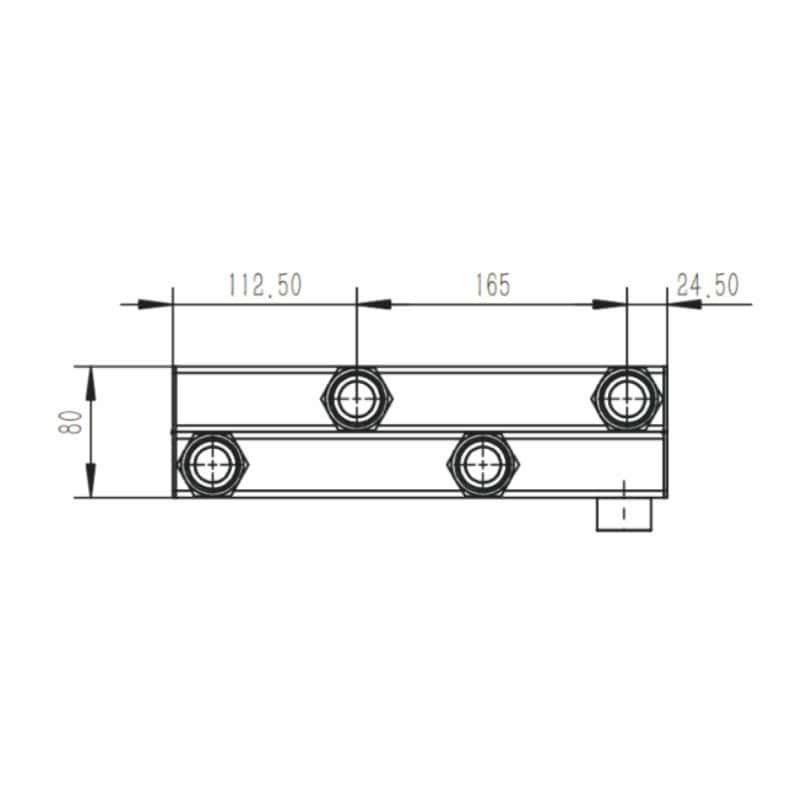

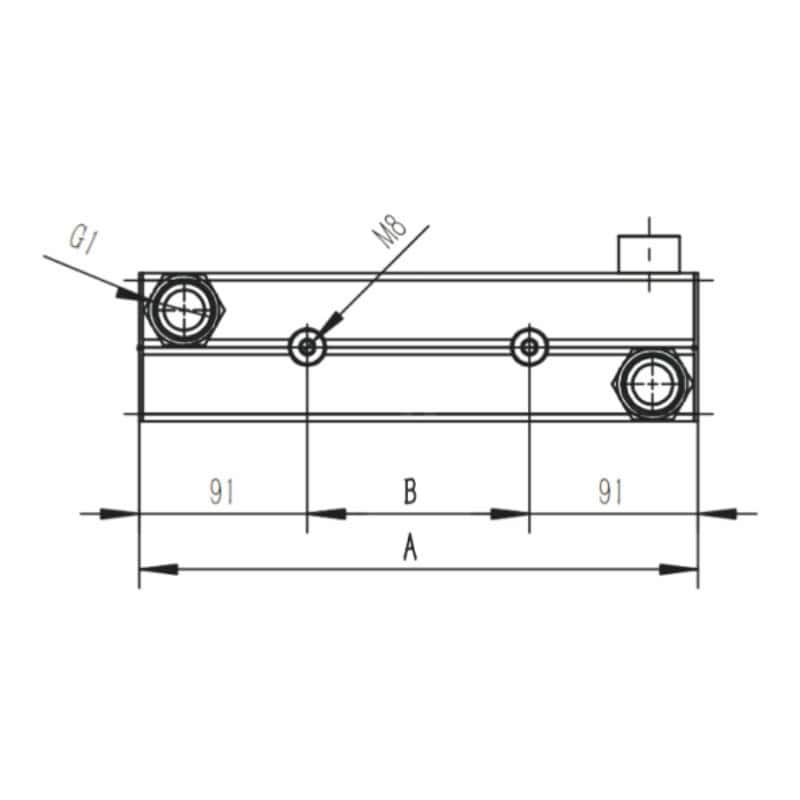

Our factory has specialized technical engineers to provide design solutions for the Distribution Manifold. They will assist in handling product specifications and 3D drawings. Generally, the number of circuits for a manifold ranges from 2 to 12. However, if you want to customize 13 or 15 circuits, we can also design according to your needs. We ensure that the final Distribution Manifold meets the unique project requirements of the customer. Our engineers will provide you with the solution within 7 working days for your selection.

3. Can the material of the Distribution Manifold be changed?

Of course, the material of the Distribution Manifold can be replaced. Our standard custom Distribution Manifolds are usually made of 304 stainless steel. However, our factory offers a “free raw material selection” service. We can provide a variety of materials, such as 304/316L stainless steel, brass, bronze, lead-free brass, and copper. We can discuss the specific selection together. Of course, you can also obtain free samples first before deciding whether to place an order.

4. Does the Distribution Manifold have ISO9001 certification?

Yes! Our Distribution Manifold has ISO 9001 certification. The quality management system of our factory has not only obtained ISO 9001 certification, but also passed UL and RoHS certifications. Therefore, our products are also sold to regions such as the United States and Europe. This breaks international trade barriers. They are widely used in local heating, ventilation, and air conditioning projects as well as smart home water systems. They have become the preferred supply chain products for many overseas partners.

5. What is the defect rate of the Distribution Manifold made in your factory?

Plumberstar’s Distribution Manifold has a defect rate below 0.1%.

Our factory is fully certified to ISO 9001, UL, and RoHS standards throughout the entire production cycle. This includes selecting stainless steel raw materials, CNC machining, integrated assembly, and multiple rounds of quality inspection tests covering pressure resistance, sealing performance, and flow balance verification. All products undergo a 100% comprehensive inspection before leaving the factory.

Moreover, we have implemented a traceable quality management system. Each manifold is marked with a production batch code. Even if a defective product is indeed found, we can rely on the production batch code to track the entire process from raw material procurement to after-sales service, identifying which link went wrong. We can also investigate and recall products based on the production batch code. This strict quality control provides strong support for long-term customer cooperation in the global market.

6. What is your process for calibrating the flow meters on the manifolds?

The flow meters we assign to manifolds are calibrated through a rigorous multi-stage process. This process complies with international metrology standards, ensuring high-precision flow measurement for hydraulic balancing in heating systems. The detailed workflow is as follows:

- Pre-calibration preparation: Before calibration, each flow meter undergoes a structural integrity check. The manifold components are pressure-tested to eliminate leaks. Then, the manifold is connected to a standardized calibration device equipped with a high-precision reference flow meter and a constant temperature water circulation system to simulate the operating conditions of actual heating systems.

- Multi-point accuracy calibration: We perform calibration at 5-7 typical flow points. These flow points cover the entire operating range of the flow meter. Simultaneously, the readings of the manifold flow meter and the reference flow meter are recorded, and the deviation is calculated. The allowable error range is strictly controlled within ±2%. This threshold meets the requirements of EU and North American heating system standards.

- Temperature compensation verification: Since the heating water temperature can affect the accuracy of flow measurement, we conduct additional calibrations at three key temperatures common in heating systems (40°C, 60°C, 80°C).

- Post-calibration confirmation and documentation: Each qualified flow meter is marked with a calibration certificate number. We maintain complete test data, operator information, and test dates for each manifold. This record is available free of charge.

- Regular recalibration guarantee: We also implement a regular calibration audit system for production line equipment. All reference flow meters are sent to accredited laboratories for recalibration every year. Moreover, we conduct internal verification of the calibration process every quarter to maintain long-term accuracy and stability.

7. What are the payment terms for the Distribution Manifold?

Our available payment methods include: T/T, L/C, DP/DA. Customers can choose their payment method flexibly. The standard terms are as follows:

1. Telegraphic Transfer (T/T): A 30% deposit is paid after order confirmation, and the 70% balance is paid against a copy of the bill of lading. This is the most commonly used term for our large-volume orders.

2. Letter of Credit (L/C): For large-volume purchases (≥500 sets), irrevocable sight letters of credit are acceptable. The letter of credit needs to be issued by a well-known bank recognized by both parties.

3. Documents against Payment/Documents against Acceptance (DP/DA): Applicable to long-term cooperative customers with a good credit record. Approval from our financial department is required.

8. Can the Distribution Manifold be shipped directly to my warehouse in Germany?

Absolutely. We can ship the Distribution Manifold you ordered directly from our factory to your warehouse in Germany.

Our end-to-end service is specifically designed for this purpose. We will coordinate and arrange for efficient direct transportation from the factory to your facility, or even to your doorstep. Whether your order is FCL or LCL, we can accommodate it.

We also offer shipping terms such as DDU and DDP. We can handle the logistics through to your designated location in Germany. Our products comply with CE, ACS, and other EU requirements. Therefore, the procedures for the European market have been simplified. You can rest assured that you can leave the complexities of international transportation to us.