Description

|

Straight-Through Female Joint

The structural characteristics of the straight-through female thread joint are that both ends or one end have a female thread interface, and the internal flow channel features a linear design, which enables a non-bending butt joint in the pipeline system. It is a basic connector in industrial and civil piping systems. Applications include the linear extension of pipelines, the fixed connection of equipment and pipelines, the docking of branch pipelines, and the rapid connection during maintenance and replacement.

|

|

|

Water Meter Coupling

The water meter connector is a specialized fitting for water meter and pipe system design, featuring either a threaded connection or a compression connection structure. It is compatible with various water meter interface specifications and pipe sizes. The purpose is to establish a sealed connection between the water meter and the inlet and outlet pipelines, while also considering the convenience of installation and the flexibility of disassembly, which facilitates future maintenance, calibration, or replacement of the water meter.

|

|

|

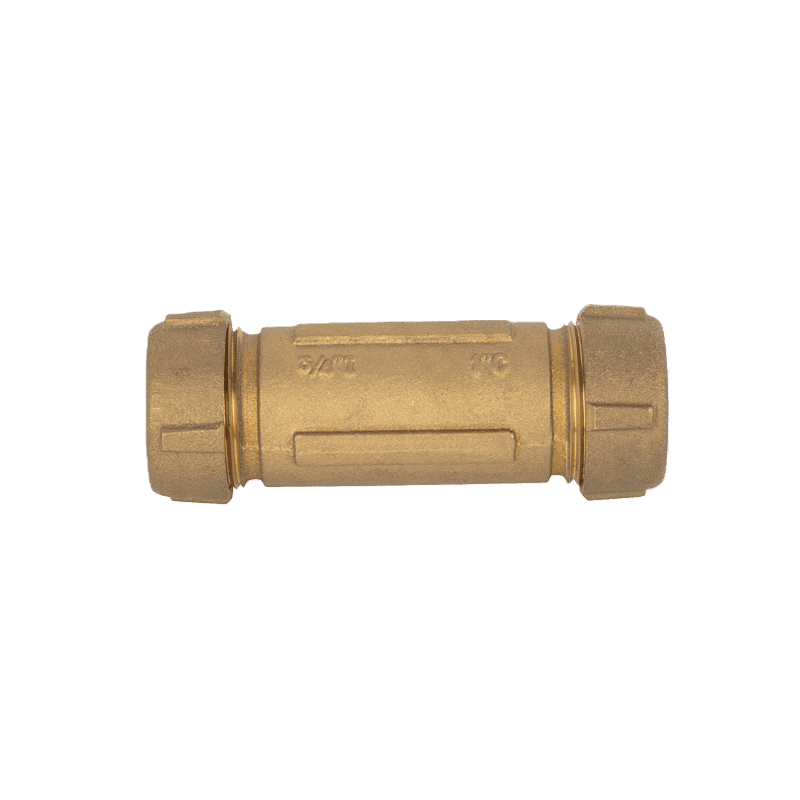

Brass Sleeve Coupler

Brass sleeve coupling structure with hollow sleeve as the main body, through key connection, set screw, or interference fit, to achieve a rigid connection of two coaxial transmission shafts. It is used in general machinery, fluid equipment, instrumentation, water supply and drainage systems, and industrial automation equipment, including transmission torque, compensation for shaft installation deviation, and ensuring the concentricity and stability of equipment operation.

|

|

Lead-Free Push-Fit Coupling

The advantage of the Lead-Free Push-Fit Coupling is its push-in, quick-fit design, which eliminates the need for welding, threading, or special tools and automatically locks the seal by inserting the pipe into the joint. Widely used in scenarios with high environmental requirements for materials, including the rapid connection of pipelines, system expansion, equipment connection, and maintenance replacement.

|

|

|

Push Fit Male Coupling

Push-Fit Male Coupling is a high-efficiency pipe fitting that combines a quick plug connection with a male thread structure. No welding, threading, or special tools are required. The pipe insertion joint can be quickly locked by an internal sleeve or a sealing ring, and the male thread end can be directly matched with the pipe, valve, or equipment interface that has an internal thread.

|

|

Push-In 90 Degree Elbow Coupling

The Push-Fit 90-Degree Elbow Coupling is a core fitting for pipe connections that integrates push-in quick-fit construction with a 90-degree bend flow design. The advantage is that no welding, thread winding, or special tools are needed; just push the pipe directly into the joint, and the 90-degree elbow construction can accurately change the pipe direction, adapting to installation scenarios with limited space or vertical turning.

|