Description

|

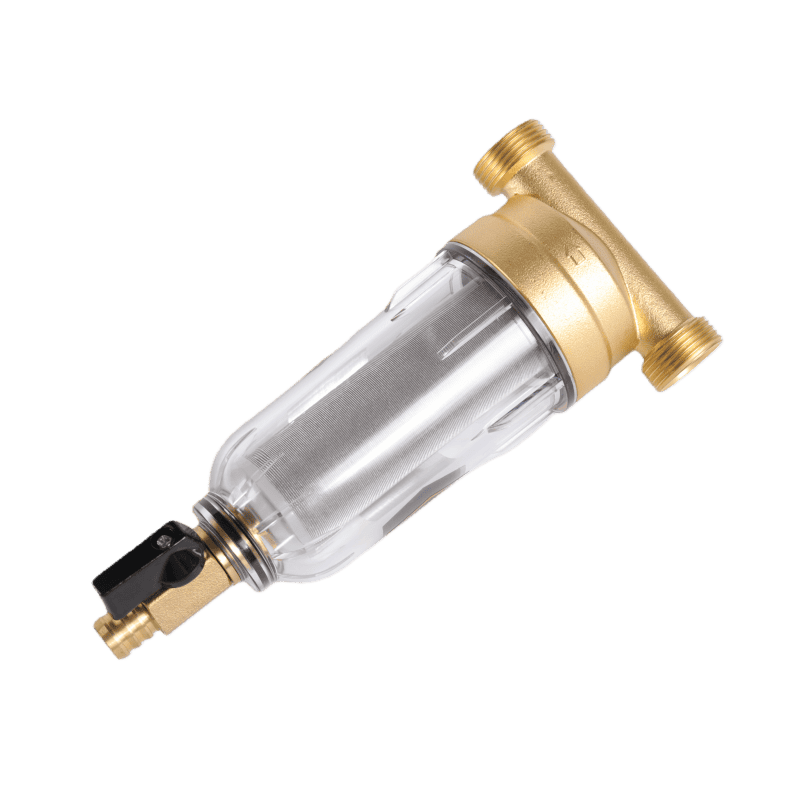

Water Purifier Filter Valve

The 60μm water purifier filter valve can both control the water on and off and catch dirt in the water. It can realize start-stop control, backwashing operation, or branch switching of the water purifier system, thereby avoiding large particle impurities from blocking the water purifier filter element. It helps the filter last longer, cleans the water first, and keeps the clean water flowing in a stable and safe way.

|

|

|

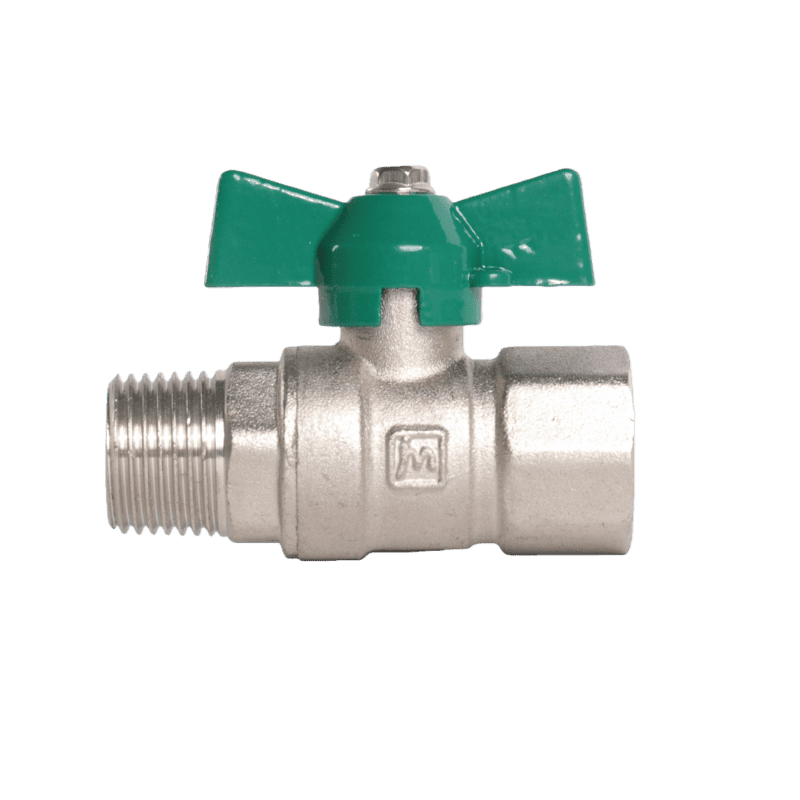

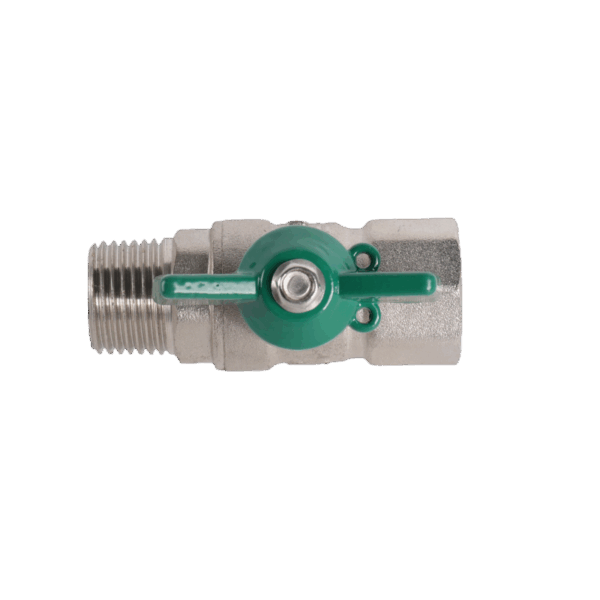

Butterfly Handle Globe Valve

Butterfly handle globe valve works by moving the valve disc up and down along the center line of the valve seat. In this way, it can turn the flow on or off, and it can also adjust the flow size step by step. It is suitable for places where good sealing and accurate flow control are needed. It supports BSP, NPT, and other international standard threads, so it is easy to install in different countries and regions. Because of this, it is widely used in industrial pipelines and home plumbing systems, and is an important basic fitting in piping systems.

|

|

|

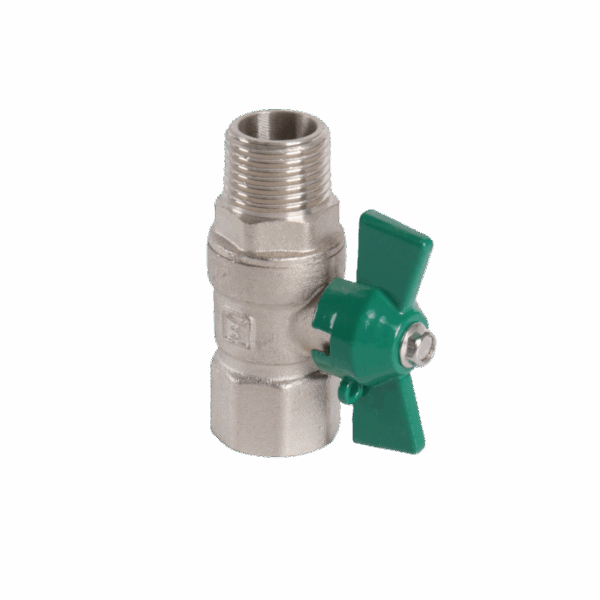

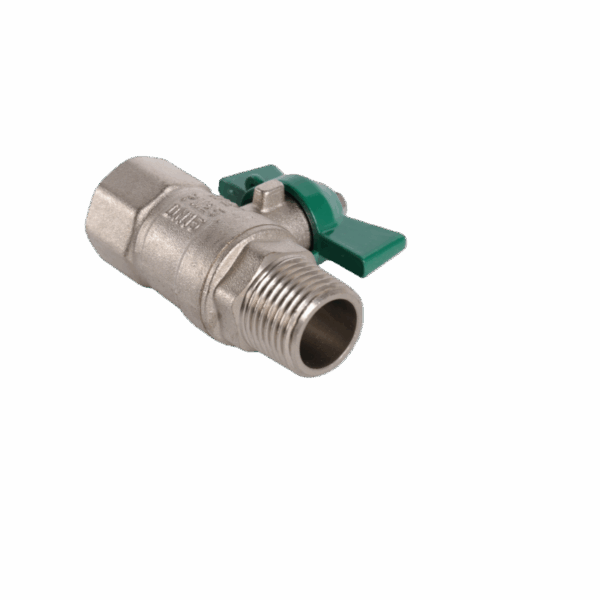

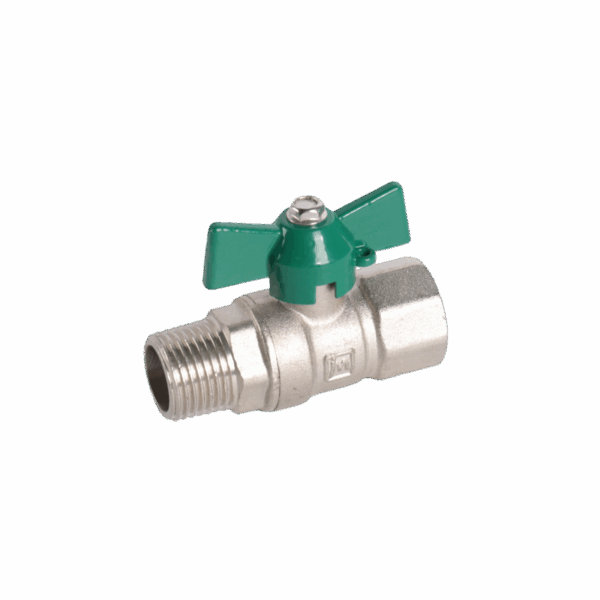

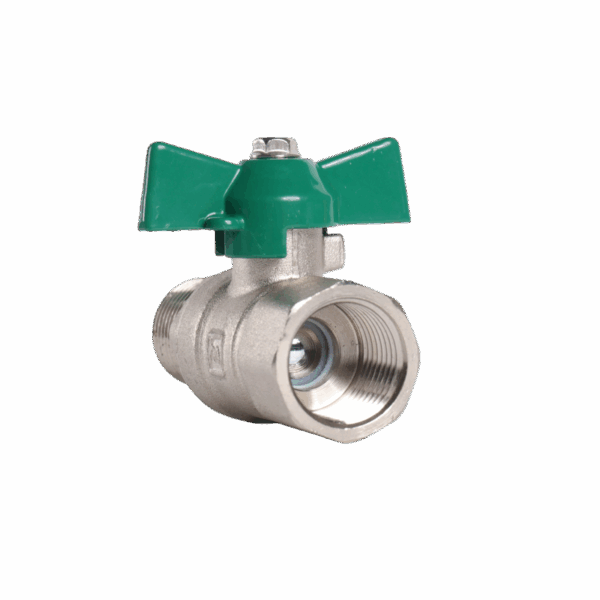

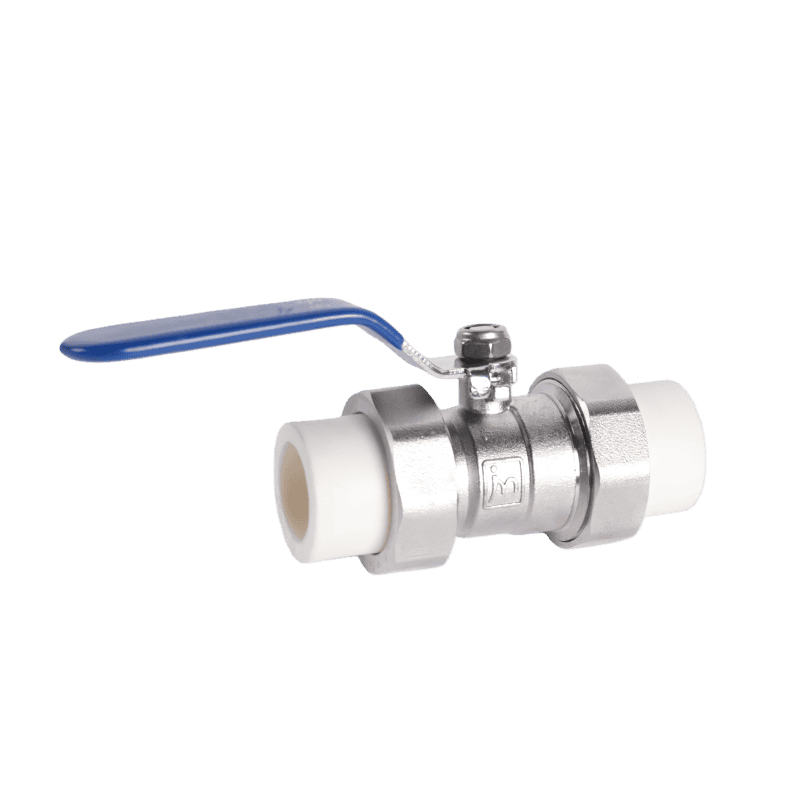

PPR Stainless Steel Ball Valve

The PPR brass ball valve is achieved through the rotation of the brass spherical spool to achieve rapid medium on-off. When the handle is turned, the valve can open or close quickly, making it easy to use. This valve is widely used in home and commercial hot and cold water systems, water supply and drainage projects, and some chemical liquid pipelines. It is especially suitable for flow control in PPR piping systems.

|

|

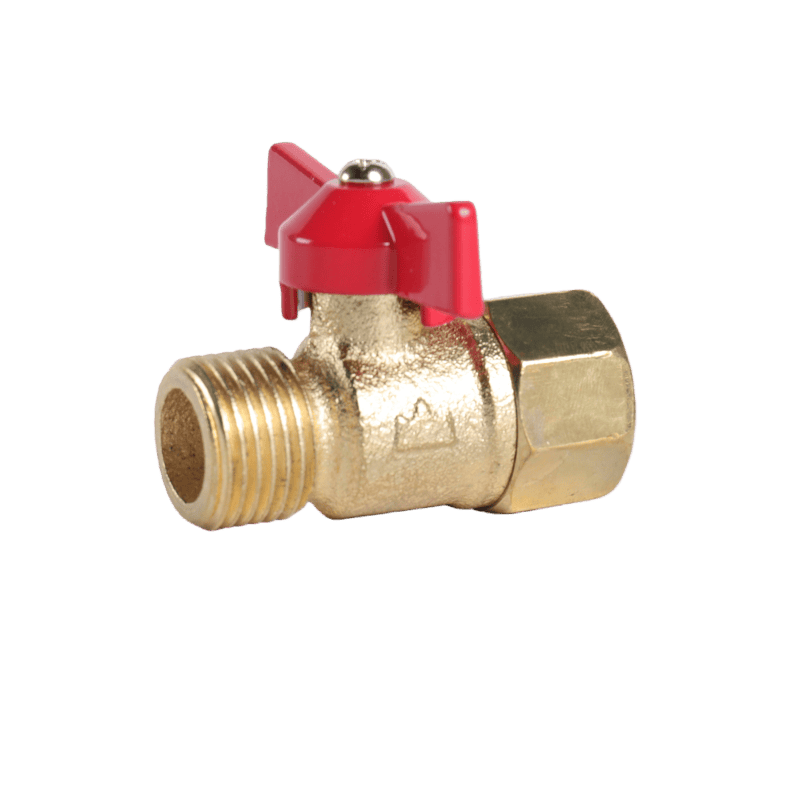

Compact HPVC Ball Valve

Compact HPVC ball valves are made to save space. The valve body is small, so it can be easily installed in narrow or crowded pipe areas. Even though the size is small, it still has good sealing and smooth water flow with low resistance. This valve works well in places where the installation space is limited, and the fluid may be corrosive. It is suitable for small and medium-sized piping systems to control different media efficiently. Because it is lightweight and environmentally friendly, it also meets the needs of international and cross-border projects.

|

|

|

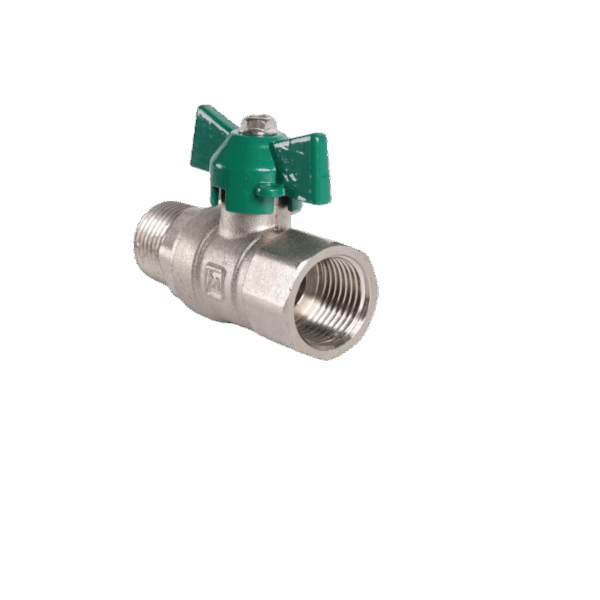

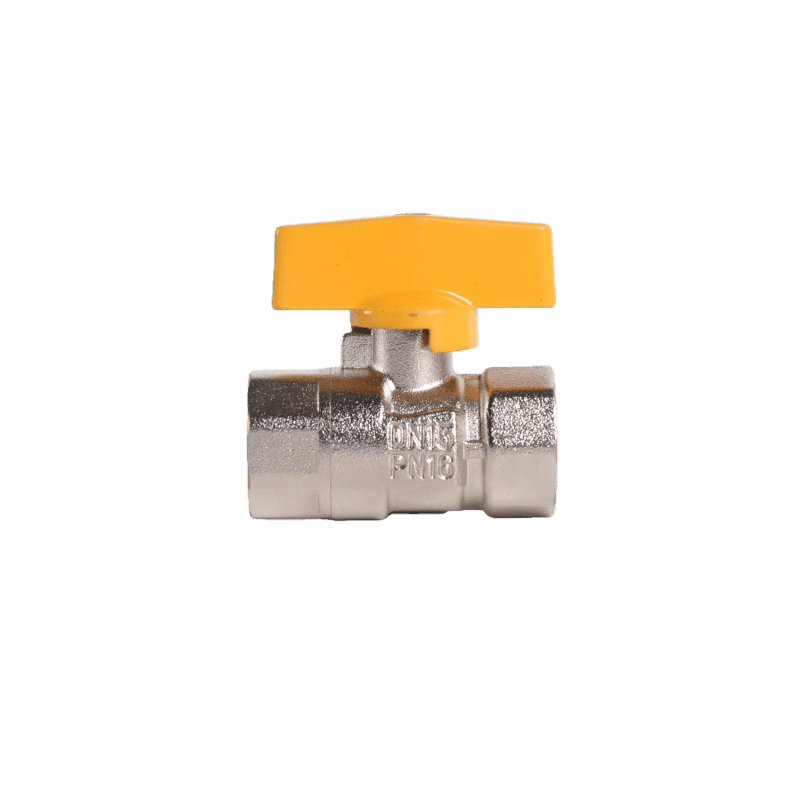

Yellow Wing Handle Ball Valve

The yellow wing handle ball valve is mainly made of brass, which is strong and durable. It uses a yellow wing-shaped handle that is easy to see and easy to hold. The wide handle gives a better grip, so turning the valve is simpler. The bright yellow color helps engineers quickly find and identify the valve in complex pipeline systems. It also helps tell different valve functions apart, making pipeline management and maintenance easier and more efficient.

|

|

High Platform Flanged Ball Valve

The circular pumping station pipe is an important part of a pumping station system. It has a round shape, and it is mainly used to carry and guide water or other fluids in heating and water supply systems. Its circular structure features low fluid resistance, high pressure-bearing capacity, and stable compression and impact resistance. This extension pipe helps increase the distance between system parts. It is very useful when the system layout needs to be changed or adjusted.

|