Description

|

|

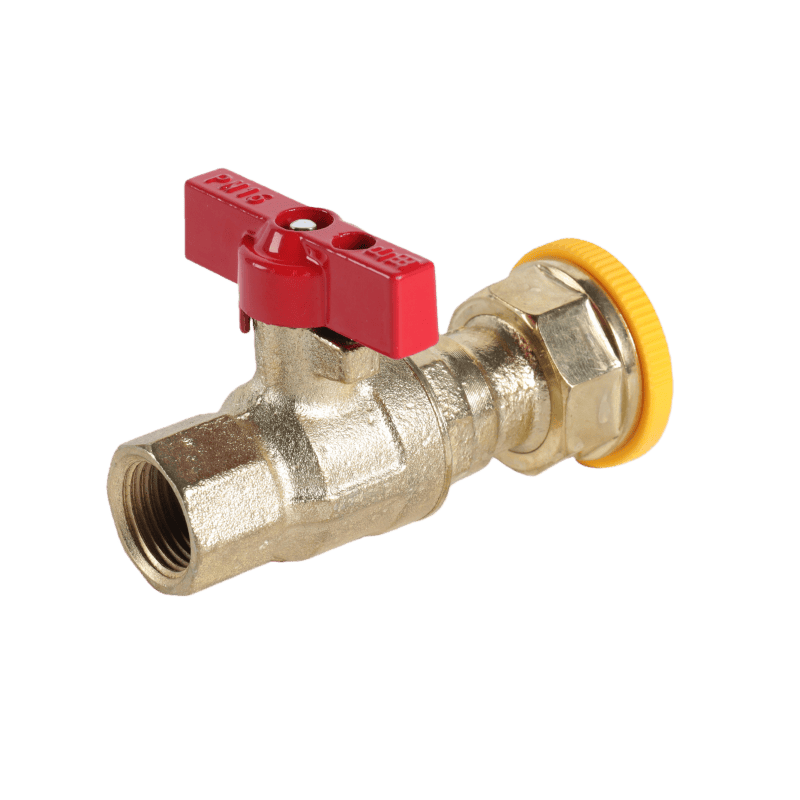

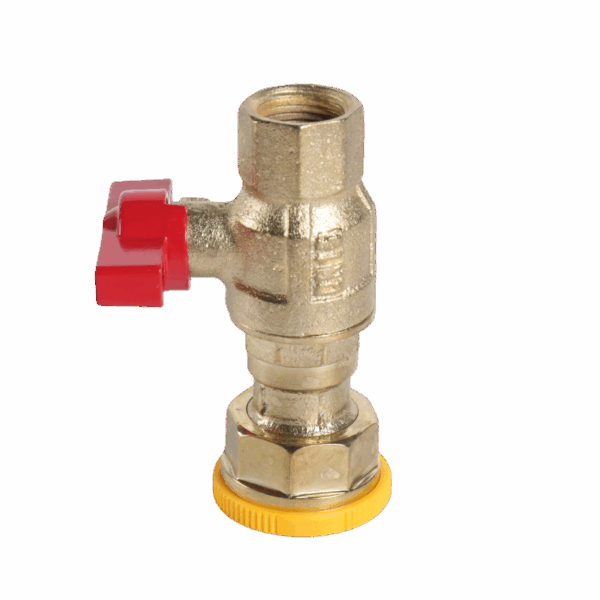

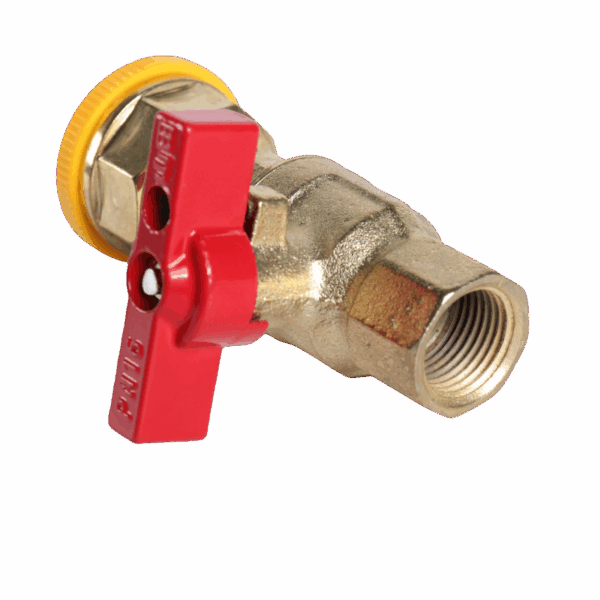

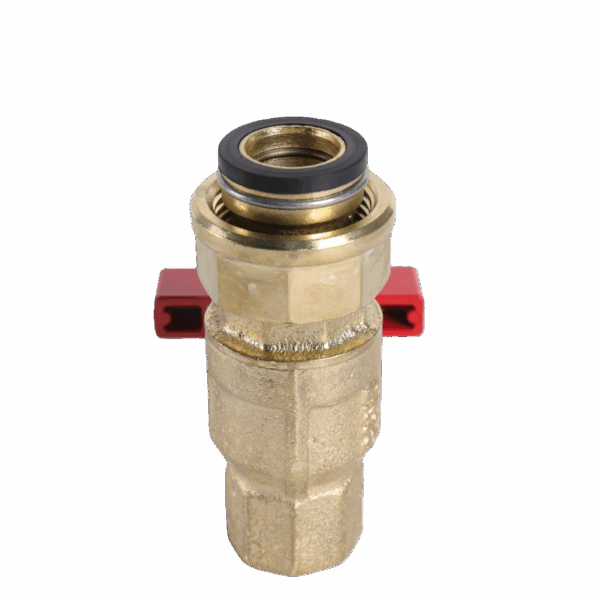

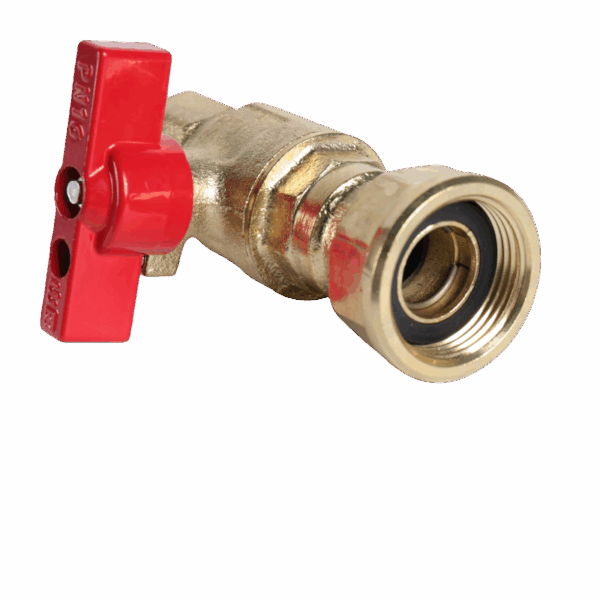

Brass Quick-Opening Ball Valve With Lock

Brass male locking quick-opening ball valves have a handle that opens and closes quickly. The handle also has a lock, which stops it from being opened or closed by mistake or by unauthorized people. These valves are mainly used in small and medium pipe systems, such as water supply, drainage, gas, and HVAC systems. They help make pipe use safer and easier to control.

|

|

|

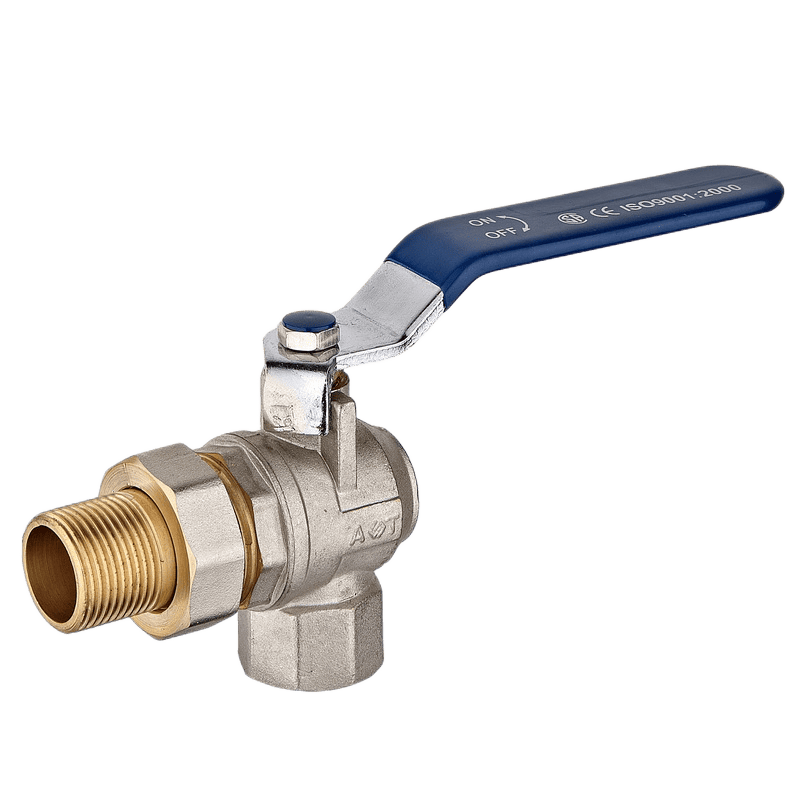

M x F Gas Butterfly Handle Ball Valve

M x F Gas butterfly handle ball valves are made of materials suitable for gas media, usually brass or cast steel. It is mainly used in the middle and low-pressure pipeline nodes of the gas transmission system, as well as in pipeline control position scenes, and can achieve 90-degree fast on-off of the gas passage. The threaded interface adapts to the standardized connection of most gas pipelines.

|

|

|

Male x Female Miniature Brass Globe Valve

Male x Female miniature brass globe valves are small in size and fit well in tight spaces. They can turn the fluid on or off and also control the flow smoothly. They are mainly used in small pipe systems with small diameters and low pressure, making fluid control easy and flexible.

|

|

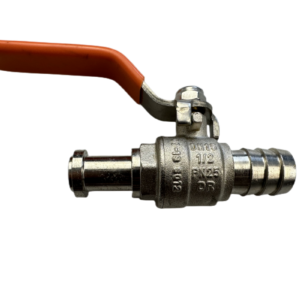

FIP Full Port Lead Free Brass Ball Valve

The FIP full-bore lead-free brass ball valve has an inside channel that is almost the same size as the pipe. This lets the fluid flow easily with very little resistance. It is made from environmentally friendly material and is good for systems that need a high flow rate. The valve can open and close quickly and is suitable for low to medium-pressure pipes carrying clean fluids.

|

|

|

Male Three-way Brass Ball Valve

The FIP full-bore lead-free brass ball valve has an inside channel that is almost the same size as the pipe. This lets the fluid flow easily with very little resistance. It is made from environmentally friendly material and is good for systems that need a high flow rate. The valve can open and close quickly and is suitable for low to medium-pressure pipes carrying clean fluids.

|

|

Y-Type Filter Ball Valve

The Y-Type Filter Ball Valve is a two-in-one valve. It can turn the pipe on or off and also filter dirt at the same time. It uses a Y-shaped filter and a ball valve inside. This helps stop dirt from going into the pipes and protects the equipment from damage or blockage. Rotating the ball valve handle can quickly control the on-off of the pipeline. The interface is of standard thread or flange specification and can be directly connected in series in the pipeline.

|