FAQs of Hydraulic Arrow with Manifold

1. Can the number of outlets for the Hydraulic Arrow with Manifold be customized?

Yes, the number of water outlets of the Hydraulic Arrow with Manifold can be customized.

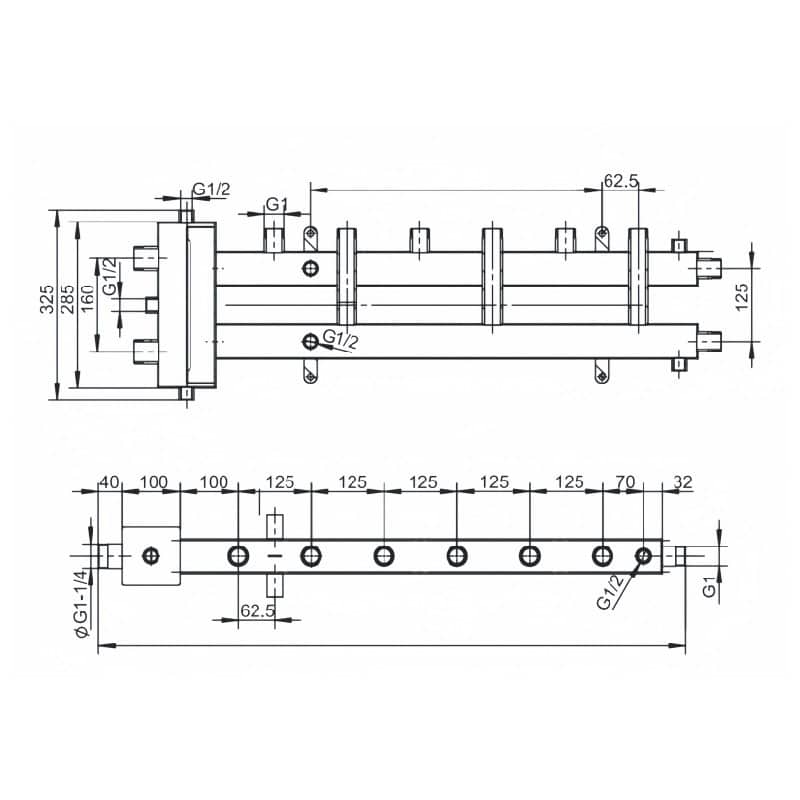

Plumberstar can provide customized heating manifold solutions. Generally speaking, manifold products can offer options ranging from 2 circuits to 12 circuits. Customers can customize them according to their usage needs. This customized design aims to ensure that the manifold can distribute the correct flow rate to each circuit to meet its specific heating load. And customized zone control can be achieved by adding actuators to different circuits.

If customers are not sure how many circuits to customize, our engineers can assist them in formulating specifications and designing 3D drawings. They can also provide multiple design schemes for customers to choose from.

2. How can I get a wholesale price quote for a container load of Hydraulic Arrow with manifolds?

If you wish to obtain a wholesale quotation for a container of Hydraulic Arrow with Manifold, you can follow these steps:

1. You can first make an inquiry to get in touch with us.

• Use the “Get Quote Now” or “Send Inquiry Now” button on the Plumberstar website.

• Send an email to info@plumberstar.com.

• Call directly at +86 159 6864 8802.

2. We need you to provide details of the project, including the approximate quantity for one container, the schedule, the type of sea freight service you need, the destination, and any specific quality control measures, etc.

3. After the above contact, we will provide you with our wholesale quotation based on the quantity of Hydraulic Arrow with Manifold. When the product quantity reaches a certain level, we can offer you tiered discounts.

3. How to package the Hydraulic Arrow with Manifold?

To ensure that the Hydraulic Arrow with Manifold is delivered to customers in perfect condition. We will implement a series of packaging measures to prevent collision, moisture, and displacement of the product.

For corrugated cartons, we will choose those with a specification of 5 layers or more, and for wooden cases, we will use solid wood with a thickness of ≥15mm. Inside the packaging, we will fill buffer materials such as bubble wrap, pearl cotton, and foam blocks. Desiccants will also be placed inside the packaging, and the outer layer can be covered with a waterproof plastic film or a waterproof carton. The product can be fixed on a pallet with packing straps. And stretch film to form “palletized packaging” to avoid tipping during transportation.

At the same time, we will clearly mark some basic information on the outside of the packaging. We will also affix internationally general warning signs and indicate the weight and volume according to the characteristics of the goods. This facilitates carriers in calculating freight, planning container loading space, and avoiding overloading of handling equipment due to unknown weight. In this way, we can try to prevent misdelivery, incorrect pickup, or loading and unloading errors.

4. How to apply for a free sample of Hydraulic Arrow with Manifold?

We offer free samples of Hydraulic Arrow with Manifold! How to apply:

You can contact us directly by sending an email through our official website https://plumberstar.com/. Our professional team of engineers will communicate with you to understand your specific requirements and specifications for the product. After confirming the customer’s needs, we will send you samples that meet the requirements. You only need to pay the shipping cost.

We provide free samples to demonstrate our manufacturing strength and product quality. Whether it’s our manifolds, valves, or other pipe fittings, we are confident in satisfying your customers. Samples will be ready within 15 days.

5. What costs are saved by purchasing the Hydraulic Arrow with Manifold directly from the factory?

By partnering with Plumberstar, you can significantly reduce costs in the following ways:

1. Factory direct sales price: The most direct cost savings come from the “factory direct sales price” we offer. Every penny is spent on the product itself. There is no need to pay extra for intermediate links.

2. Free services: We provide a range of free services. We offer free samples and free sample testing. You can personally inspect the product quality before making a decision. We provide free comprehensive testing for 100% of our products. We also offer free testing reports, including even third-party testing reports. This saves you a substantial amount of money on quality inspection expenses.

3. Reduced operational and risk costs: We support a minimum order quantity as low as 100-500 units. This allows you to manage inventory more flexibly, reducing capital occupation and warehousing costs. Moreover, if any damage occurs during logistics and transportation, we will provide free replacements. We also offer a three-year quality warranty service.

4. One-stop solution to save hidden costs: We provide end-to-end one-stop services from initial design to final delivery. Our technical engineers can assist you in completing specification formulation and 3D/CAD drawing design, which saves you valuable time and the hidden costs of finding and coordinating multiple suppliers.

6. Does your company support private labeling for the Hydraulic Arrow with Manifold for distributors?

Of course, we support it! Providing private brand services to our distributor partners is our core advantage.

- Brand customization: We can directly engrave your brand name on the product.

- OEM/ODM solutions: With nearly 20 years of customization experience, we will provide flexible solutions, including sticker design and mold development.

- Customized packaging: We also offer customized packaging solutions, with options including neutral packaging, cartons printed with your brand, and palletized export packaging. It can be customized according to the standards and requirements of different countries.

We are committed to helping you build and promote your own brand product lines and enhance market competitiveness through these services.

7. Is your quoted price for the Hydraulic Arrow with Manifold an all-inclusive ex-factory price?

Our quotation can be just the ex-factory price of the product, or it can be an “all-inclusive price” that covers all expenses. The choice is yours, and our goal is to provide you with the most convenient and cost-effective solution.

Our offer can be customized according to your specific needs. We offer “Factory Direct” as the basis for all our offers. However, whether the final offer includes other charges depends on the terms of trade we have mutually agreed upon. We support a variety of international trade terms, including: EXW, FOB, DDU, and DDP. During our collaboration process, we define your project details, such as order volumes, quality control requirements, and timelines. We will send you a detailed quotation that clearly sets out the price terms agreed upon between us.

8. Will you keep the molds for the Hydraulic Arrow with Manifold custom project?

We are responsible for the proper storage of the special molds developed for custom projects and ensuring that they are only used for producing your orders. When you place your next order, we can proceed directly to production, saving time and costs. Using the same set of molds also ensures that each batch of your products remains consistent with the previous batch, avoiding issues caused by differences in molds. This is not only for production convenience but also to protect your design investment and commercial interests. We will clearly stipulate the ownership, storage, and usage terms of the molds in the cooperation agreement at the initial stage of the project cooperation to ensure that your rights and interests are fully protected.