Description

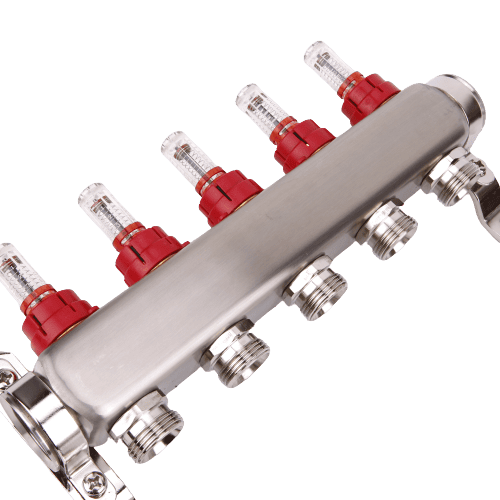

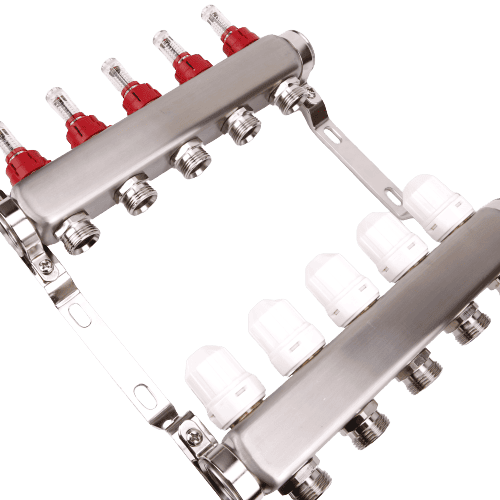

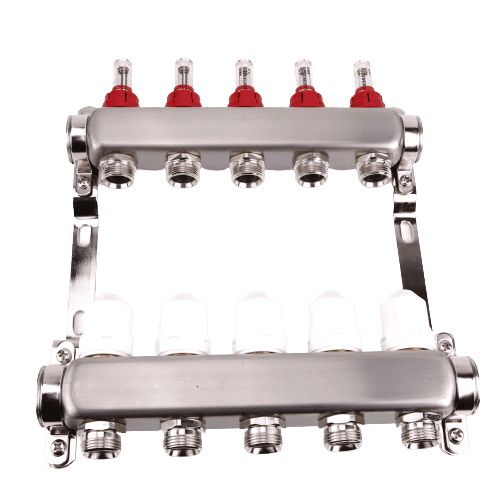

Ground Heating Manifold

JX-0705

- Stainless steel Manifold

- High-Quality SS304 body and manufactured to standard.

- Preassembled and “ready for installation” with all necessary components inbuilt.

- Available in various sizes for any design type or specification.

- It patented pipe connections for various pipes and sizes.

- 3/4″X20; 3/4″x16 adapter

- PEX Manifold adapters with the Manifold are compatible with any PEX tubing – but we have no adapters, Compression type connections & push fittings for ease of installation

- There is an automatic float-type air vent for air elimination purposes. It also includes a cap for pressure testing purposes.

- Manufactured from corrosion-resistant and durable Stainless Steel to last for life

- Compatible with any PEX tubing – no special adapters needed

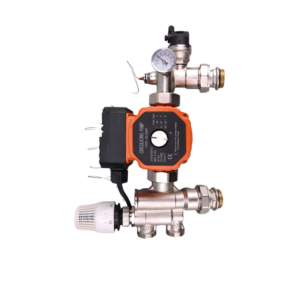

- The function of a manifold is to distribute the correct flow to each loop to meet its specific heating load. This is achieved by balancing each loop to complete the design flow requirement. Customized zoning can be achieved by adding actuators for the different loops controlled by thermostats. Each room would then be a zone, allowing the thermostat to open and close the valve to the room as required. It is possible to control a zone valve or the pump for simpler one-zone systems. Zoning rooms with different loads or seldom occupied allows you to keep those areas at a lower setting, saving energy without sacrificing comfort elsewhere.

- Technology makes our life more accessible nowadays. We can make our houses, offices & factories comfortable in the heating issue. A heating manifold is a control hub for the central heating system. It acts as a central system. It connects the supply & return lines. The primary purpose of the heating manifold is the water distribution of hot & cold pipes. It happens systematically. It means radiant Heating and cooling systems. Supply water enters the Manifold from the heat source. Then it circulates hot water throughout the system. We can adjust a Heating Manifold with the pumped heat source. Most heating manifolds are made of stainless steel. It can be as simple as a copper unit with supply and return ports with a shutoff valve for each supply. Heating Manifolds are simple in nature and function. A manifold is like a crossing where water comes in from one end and goes out from another. Supply water enters into the Manifold. Then it flows through a heating system.

-

Each heating system has at least two manifolds: a supply and a return manifold.

- Underfloor Heating Manifold: Underfloor Heating means the distribution of warm water to each underfloor heating zone. For this Heating, you can use a Manifold. It distributes water at the best temperature from the boiler (via a blending valve). Also, from the heat pump. It directs water to each Heating tube maintaining the correct flow rate. These heating manifolds can warm different zones with different temperatures. And It depends on the user’s demand and house supply of Heating. Zones are individual rooms controlled by other thermostats. Underfloor Heating is not like pumping warm water around all the tubes. The flow rate through each tube coil fluctuates based on the heat loss of the zone.

- For this reason, you should maintain the system sufficiently to ensure the flow is okay. A heating manifold acts as the control center of the system. It provides a pump for the correct flow of water into each zone to heat it to the proper temperature. Manifolds circulate heated water from the boiler or other heating source. It then goes through the underfloor circuits. Besides, it also controls the pressure and flow rates. The mixing unit can control circuit temperature as well. The underfloor heating system runs at temperatures ranging from 35 to 50 degrees Celcius. The source cannot supply the water at optimal temperature always. The thermostatic or actuated blending controls can provide. People can use a secondary circulating pump, also.

- How to Install Underfloor Heating Manifold: The design and installation of manifold systems vary. In some cases, a direct piping system is good to use. Using a heat source can accept low-temperature return water without problems. High-temperature return water is not compatible with a direct piping system. There are several types of heat sources. These sources can accommodate a natural piping system, ‘Condensing boiler,’ one of the popular heat sources for a direct piping system. There are also ‘Hydronic heat pumps’ and ‘electric boilers.’ These are fitted with natural systems. Water heaters and solar collection systems are also compatible with direct piping systems. More than one manifold station is suitable for floor coverings. The required temperature for different kinds of floor covering is different. There might have different floor coverings. The temperature of water flowing under tiles will not be the same as that of water flowing under carpets. A different temperature makes a better and more comfortable heat. Tubes used beneath tiles will produce less heat. So, tubing installed under carpeting will have more in comparison. For this type of situation, it is fruitful to use two manifold stations. One will maintain the temperature for the carpeted area and the other for the tiles. Sometimes it is more productive to split the heating system into different parts. Using more than one manifold station is not only for different floor types. Bigger houses split Manifold is also desirable. Because water has to run a long distance. The actuators act as zone valves. This helps the user to use one Manifold to control the temperature in different rooms. It is not much complicated to choose a location for a manifold station. However, this should not be a simple matter. The choice of Manifold Station location is vital thing. The main priority is accessibility. People are usually tended to install wall cavities. They want a location with easy access. Another suitable place to install a manifold station might be a closet. People also tend to hide the station behind a wall covering. In this case, you need a removable access panel. It will allow the Manifold to be accessible. People can place the Manifold somewhere within the basement of the house. One matter of fact is that keeping manifolds nearby can be cost-effective. The Mechanical room is also suitable for installing a Manifold. In this case, it should be in an exposed manner. This makes the valves accessible.

- Ready-made manifolds are available in markets with custom cabinets to install them. These cabinets are alike in infrastructure to the type used for washing machines. The metal cabinet is installed in a stud wall. People should place both the supply and return manifolds within the cabinet. People can put a perforated cover on the front of the cabinet to access the Manifold. A basement, mechanical room, or closet is not a good place to install a heating manifold all the time. The base cabinet of the kitchen or bathroom is the best alternative to it. You can be creative if you want to hide your manifold stations. For example, a window seat can hide a manifold station in the room. To access the Manifold, you can keep the top open or perforated. Plant shelves can spruce up a room and hide a manifold station. A bookcase can also hide a manifold by adding a removable panel. A heated garage is also suitable for manifold placement. Like this, there are several ways to hide a manifold. No need to take pressure to find a desirable location for manifolds. Because there is no specific place to hide the heating components.If manifold points have a tight connection, it is very much critical. If you buy a preassembled manifold, there is no chance to make assumptions about links. Should inspect all existing work and test the manifold connections. Even a tiny leak can do damage. If you put your Manifold out of plain sight, you must remain alert for tiny leaks. It can ruin your business and reputation. It is wise to test thoroughly before concealing a manifold station.