Description

Floating Valve

JX-0754

- Brass Floating Ball Valve

- It is made of brass. It has good corrosion resistance and anti-deformation performance, sturdy and durable.

- The body is adopted with high-quality brass material and treated by a hot forging process, making it stable and durable.

- Designed with G3/4 inch thread that is normally used, it can fit many pipe connections With a rubber gasket for better sealing and ensuring no leaking.

- The ball valve is used in pipelines to cut off, distribute and change the flow direction of the medium.

- We have widely used magnetic level switches and liquid level measurements. Its applicable medium is water and can withstand a wide temperature of -10℃ to 120℃.

What is a floating valve?

It’s an adverse condition that can occur at high engine speeds when the poppet valves in an internal combustion engine valve train do not correctly follow the closure phase of the cam lobe profile. This reduces engine efficiency and performance and potentially increases engine emissions. There is also a significant risk of severe engine damage due to valve spring damage and pistons contacting the valves.

Floating Valves are an important part of any water system, whether residential or commercial. They’re beneficial when you need to isolate a section of the pipe. For example, floating valves can come in handy if there is a leak and the area needs to be drained before repairs occur.

There is no one-size-fits-all answer to this question, as the best way to use a floating brass valve will vary depending on the situation. However, in general, it’s a good idea to install the valve as close to the water source as possible. This will help to ensure that the water is efficiently diverted to the desired location.

Additionally, it’s essential to ensure that the valve is installed and functioning correctly. If there is any leakage around the valve, it could cause problems further down the line. So be sure to have a qualified professional install and test your floating valves!

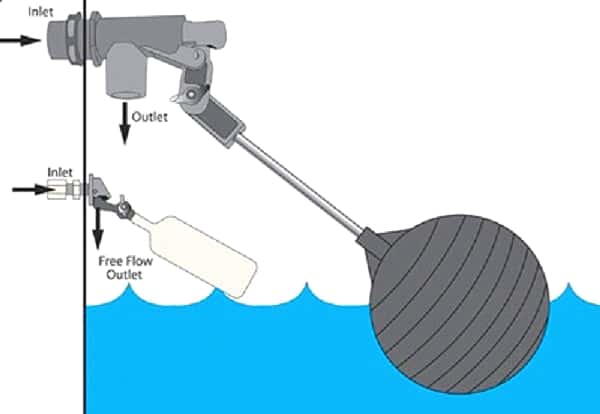

A brass float valve is a device used to control the water level in a storage tank. It works on the principle of buoyancy, where a floating ball rises or lowers with the changing water level, thereby opening or closing a valve to regulate the inflow of water into the tank.

The basic design of a brass float valve consists of a float ball attached to a stem, which moves up and down inside a valve body. The stem is connected to a brass valve that controls water flow into the tank. The valve is typically made of brass or a brass alloy, which provides corrosion resistance and durability.

In terms of size, brass float valves come in a range of thread sizes, depending on the connection size of the storage tank and the flow rate required. Some common sizes are 1/2 inch, 3/4 inch, 1 inch, and 1-1/2 inch.

Installation of a brass float valve is relatively straightforward and requires a few basic tools. It involves cutting a hole in the tank and fitting the valve body into it, securing the valve in place, and connecting the inlet and outlet pipes to the valve. This valve is installed vertically, and level, and the float ball moves freely inside the valve body.

A brass float valve is a simple yet effective device for controlling water levels in storage tanks. Its durability and resistance to corrosion make it a popular choice for water storage systems.

Additional information about brass float valves:

Besides controlling water levels in storage tanks, brass float valves can also be utilized in other related applications, such as managing the water levels in ponds, tanks, rivers, and so on. They are also appropriate for controlling various media types, including liquids and semi-solid materials.

The control accuracy of brass float valves is typically high since they can easily adjust the inlet and outlet flow by adjusting the weight of the float. Additionally, brass float valves are corrosion-resistant and can be used long-term under normal conditions.

If correctly installed and used, brass float valves can control tank systems. However, if not properly installed or used, it can result in problems such as leaks and blockages. Therefore, the manufacturer’s instructions and requirements should be followed when installing and using brass float valves.

A brass float valve for water tanks is a device that regulates the water level inside the tank. It consists of a float ball attached to a stem, which controls water flow into and out of the tank.

The design of a brass float valve typically consists of a body, a float ball, a stem, a seat, and a washer. The body is generally made of brass, which is corrosion-resistant and durable. The float ball is attached to the stem and rises or falls with the water level inside the tank. The stem connects the float ball to the valve body and controls water flow into and out of the tank. The seat is part of the valve body that the float ball seals against to control the water flow. The washer helps to prevent leaks and ensure a tight seal.

The working principle of a brass float valve is based on the buoyancy of the float ball. When the water level inside the tank rises, the float ball rises. As the float ball rises, it opens the valve and allows water to flow into the tank. When the water level inside the tank decreases, the float ball falls and closes the valve, preventing water from flowing out of the tank.

Basic information about brass float valves for water tanks includes:

- The materials used to construct them.

- The size of the valve.

- The connection type.

They are typically available in various sizes to accommodate tank sizes and flow rates. Brass float valves can be threaded or flanged and can be installed in the tank in different ways.

The connection thread sizes when selecting a brass float valve for a water tank. If the valve is too small, it may not be able to handle the flow rate required by the tank. If the valve body and thread are too large, it may not be able to control the water level accurately. Proper installation tips are also crucial to ensure that the brass float valve operates correctly and provides reliable water level control for the tank.

In terms of installations, brass float valves for water tanks can be installed in different ways depending on the application’s specific needs. Some standard installation methods include top-mounted, side-mounted, and bottom-mounted. Top-mounted valves are installed on the top of the tank and are the most common type of installation. Side-mounted valves are installed on the tank’s side and used when the top of the tank is not accessible. Bottom-mounted valves are installed at the bottom of the tank and are used in applications where the water level needs to be maintained at a specific height.

Following the manufacturer’s instructions and guidelines when installing a brass float valve for a water tank is vital to ensure proper operation and avoid problems such as leaks or blockages. It is also important to regularly maintain and inspect the valve to ensure it functions correctly and make any necessary repairs or adjustments.

In conclusion, a brass float valve is a reliable and effective way to control the water level in a water tank. A brass float valve can provide accurate and consistent water level control for many years with proper design, installation, and maintenance.