Description

|

Brass Hydrant Fire Valve

This brass fire hydrant valve is designed for fire water supply systems. It is made of brass and uses a red handwheel to open or close the valve by rotation. The valve can turn the water on and off and also adjust the flow rate. The ports are sized to match standard fire hydrant pipelines, making it a key control valve in fire water systems. An arrow on the valve body shows the water flow direction, helping ensure correct installation and reliable operation during emergencies.

|

|

|

Brass Fire Safety Sprinkler The fire sprinkler head is a key part of automatic fire suppression systems. It’s made to spray water automatically when a fire breaks out. The red liquid inside the glass bulb expands when it hits a certain high temperature. This makes the bulb shatter. Then the water starts spraying right away. It’s installed in places where fire control is a top priority. Like warehouses, industrial buildings, and other similar spots.

|

|

|

Manual Air Vent Valve Brass

A brass air release valve, also known as a vent valve or air bleed valve, is used to manually discharge trapped air in pipelines or equipment. The knurled knob on the top enables manual operation, allowing excess air in the system to be released and preventing air blockage from affecting fluid flow. It is applied in central heating systems and radiators, HVAC systems, water supply pipelines, and water storage tanks.

|

|

Water Hose Buckle Firefighting Interface

This firefighting water hose buckle coupling is a specialized quick-connect accessory. Engineered for fire hose assemblies in fire protection systems. It features corrugated socket ports at both ends. Paired with a buckle-locking design that enables rapid connection to fire hoses. This fast-acting connection mechanism is tailored to the high-efficiency demands of fire emergency response scenarios. It serves as a critical connection component for fire hoses, fire trucks, and other firefighting equipment.

|

|

|

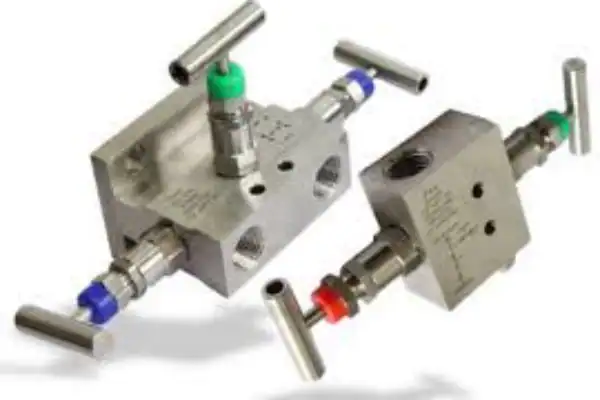

Fire Inspector Test & Drain Valve

This fire inspector test & drain valve is a specialized maintenance auxiliary valve engineered for testing and draining fire sprinkler systems. It integrates multiple ball valves and dedicated drain ports. Operating the red handle enables precise control for pressure testing and functional verification of the fire sprinkler system. As a purpose-built maintenance accessory, it is an essential auxiliary component for reliable fire sprinkler system upkeep.

|

|

Three-way Stop Fire-hydrant Valve This three-way stop fire-hydraulic valve is a specialized flow control valve engineered for fire protection water supply systems. Featuring three integrated connection ports. It enables seamless branching or merging of firefighting pipelines. Making it ideal for multi-branch fire water supply layouts. A top-mounted red handwheel controls the vertical movement of the valve stem via rotation. Allowing precise regulation of the pipeline on-off status and flow rates. As a critical component, it plays an essential role in the fire water supply system operations.

|