Description

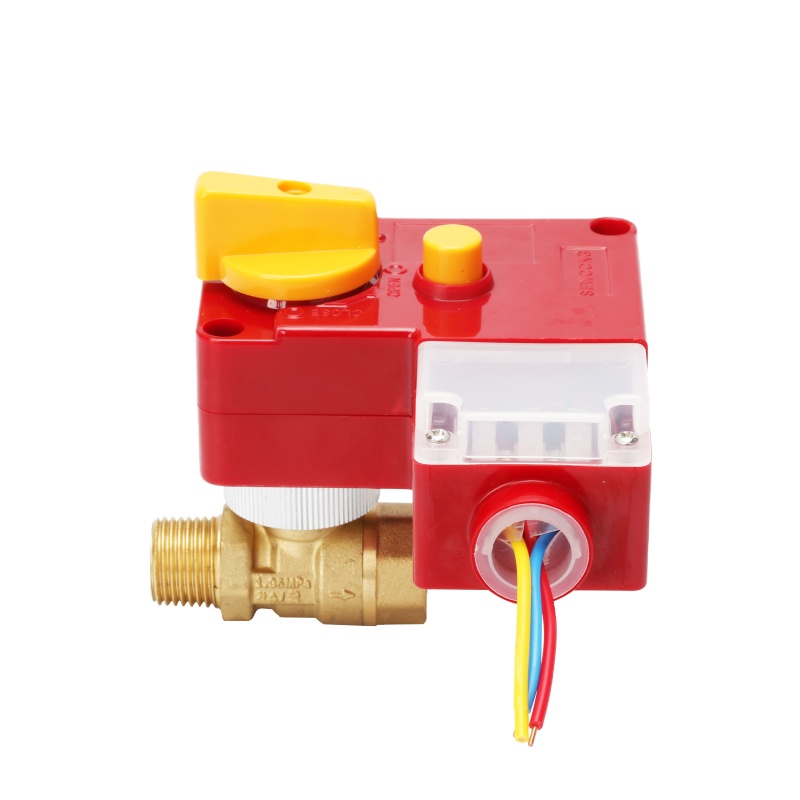

Electric Actuator Ball Hydrant Valve for Firefighting Hydrant System

JX-0328

Descriptions: Brass Forged Electric Ball Valve for Firefighting System

Material: H58-3/CW617N

Size: MF 1/2″ for the Firefighting system

Color: Brass Natural Color/Nickel Plated

Working Medium: Water

Working Voltage: DC24V

Working Pressure: 0~16 bar

Max Working Temprature: 90 °C

Operation Time: 3 ~5 seconds

Torque: 3Nm

- Body Brass

- Cap Brass

- Connection Brass

- Ball Brass

- Gasket NBR

- Seal PTFE

- Handle Steel

- Actuator ABS+Metal

Integrated manual and automatic open/close designs make your fire control operation more convenient & more innovative. Small open torque, 100000 times lifetime.

Low noise, 24V human safe voltage

Valves are used in many engineering contraptions, from water motors to engines, pumps, and the mile-long list. But the thing with valves is that they need to be operated mechanically. Well, advancement did sprinkle its goodness in the suitable ole valves, and now there are motorized ball valves available that are so much more efficient.

So, what exactly is a motorized ball valve? A motorized ball valve, also known as an actuated ball valve, is equipped with a motor. The reason behind it is pretty simple. The motor makes up for manual labor used to open and close a valve, and all of the work can be done by an electric signal that triggers the valve to operate, as needed in any machine.

Features:

A motorized ball valve can be broken down into two parts connected by a channel rod called the steam. The first part is called the valve body, and that’s pretty much the same as any other mechanical valve. The assembly has a steel ball encased in a seat, which allows for the uninterrupted spinning of the ball when the machine is operated. The electrical part of the valve is where the motor is attached with an electrical circuit and two wires to provide the necessary supply for the motorized ball valve to work its magic. The electric motor and the mechanical ball valve are connected to the steam.

Are you looking for a motorized ball valve on your plumber’s recommendation but don’t know what it is? These little plumbing gadgets consist of an electric actuator (motor) connected to a rotating ball valve. Depending on the control signal, the motor automatically opens or closes the valve by rotating the ball.

What are motorized ball valves used for?

The motorized ball valves control the flow of media (gas or liquid) with a rotating ball connected to an actuator. These valves have a plethora of uses — from the plumbing system in your house to the giant labs in chemical industries, from the water fountains of your area’s park to the large ships in the Pacific Ocean.

Why should you go for our motorized ball valves?

Here’s why you should choose to buy our motorized ball valves:

Robust design with durability

Power efficiency

Anti-corrosive

Easy installation

Most affordable price

Two-years Warranty

Our top-rated products

Here are some of our best-selling motorized ball valves:

| Features | |

| Power | Solenoid |

| Media | Water |

| Port Size |

1/2″-2″ |

|

Working pressure |

≤2.5Mpa |

|

Valve material |

BRASS

|

|

Thread end |

ISO228 |

|

IP class |

Ip56 |

|

Torque |

5Nm,5Nm,5Nm,5Nm |